Pit digging device for agricultural planting

A technology for digging and agriculture, which is applied in the field of digging devices, and can solve the problems of time-consuming and labor-intensive manual digging, affecting planting time, time-consuming and labor-intensive problems, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

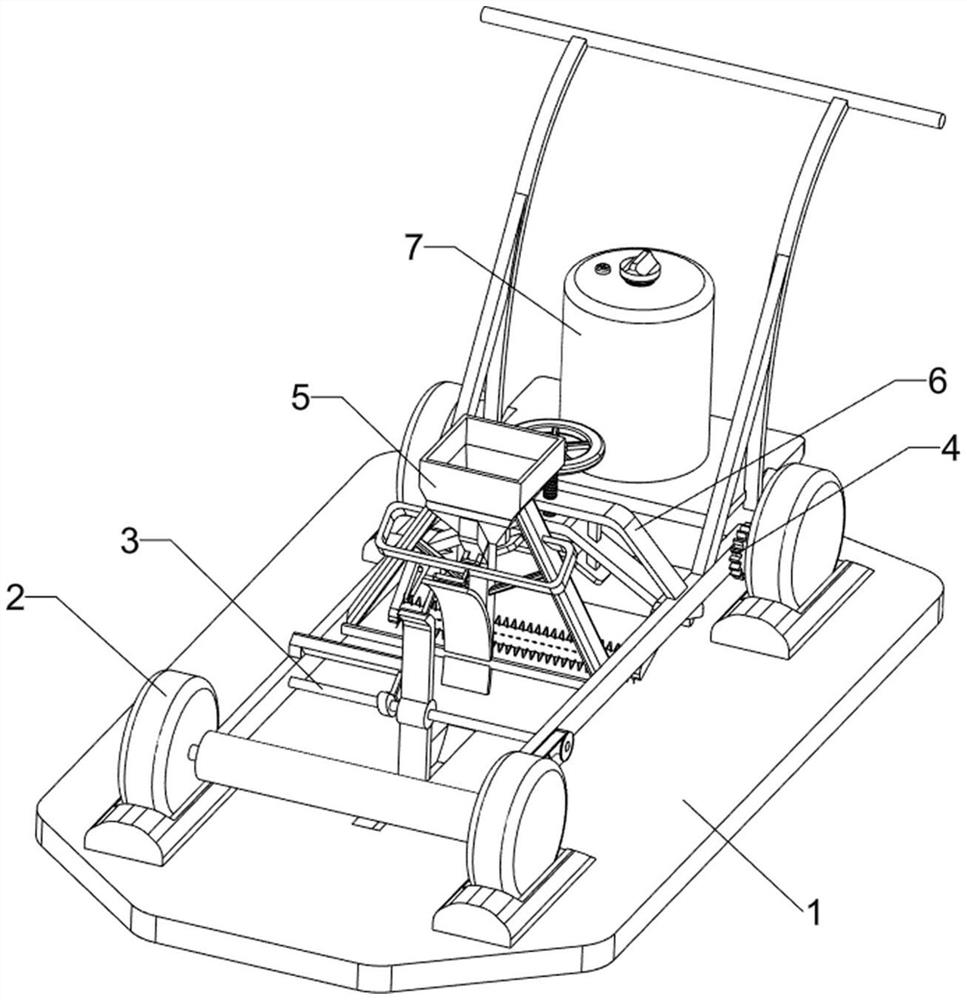

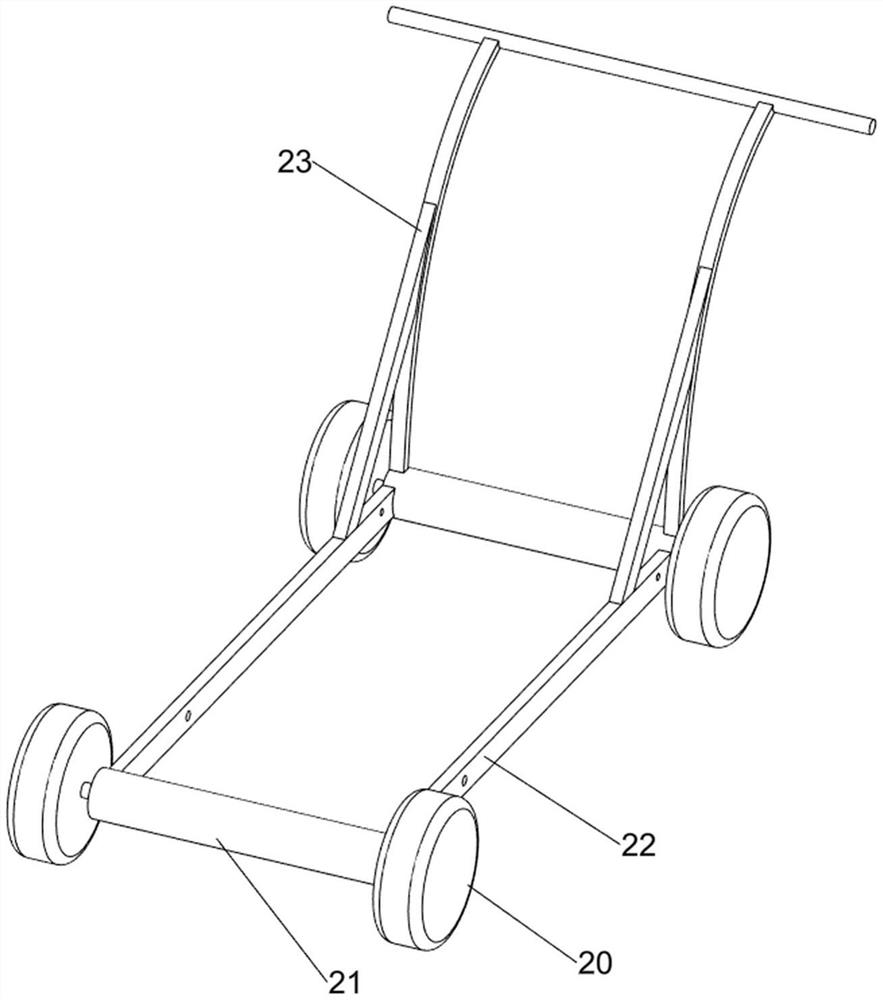

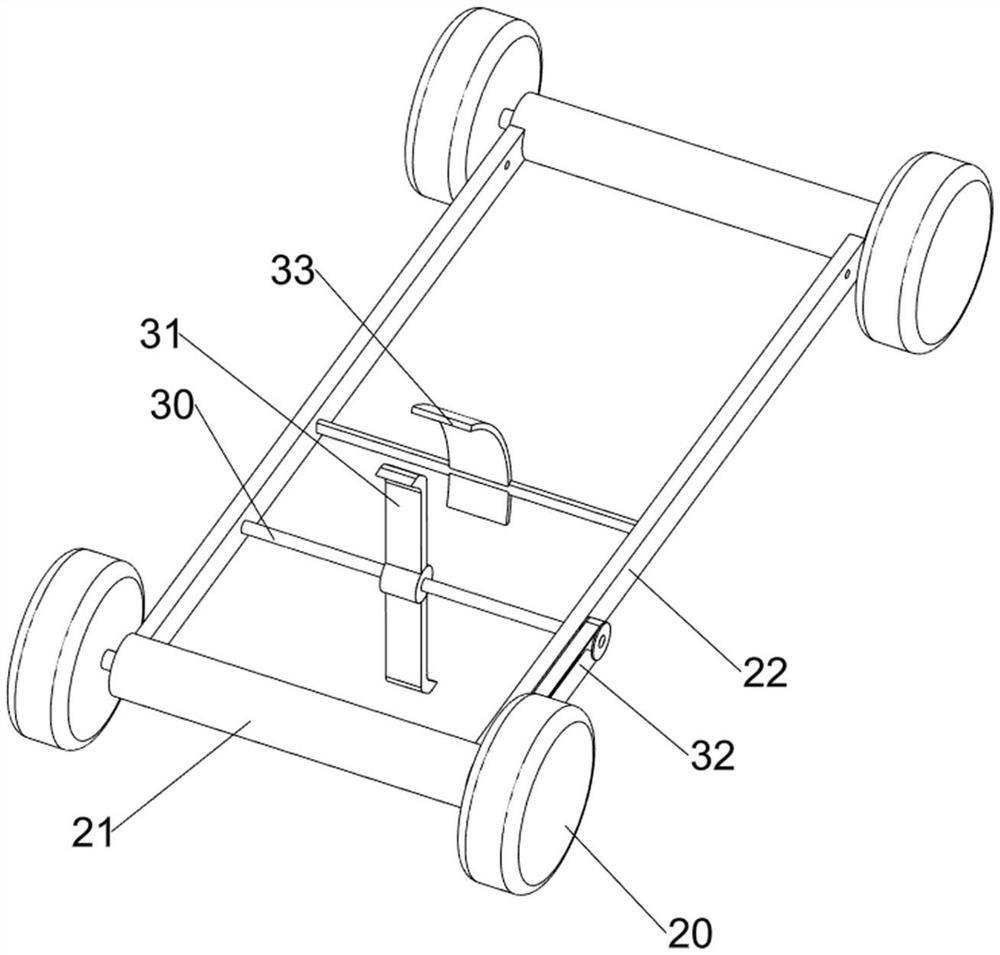

[0033] A planing device for agricultural planting, such as figure 1 , figure 2 and image 3 As shown, it includes a base 1, a moving mechanism 2 and a digging mechanism 3, the base 1 is placed with a moving mechanism 2, and the moving mechanism 2 is provided with a digging mechanism 3.

[0034] The moving mechanism 2 includes a roller 20, a first mounting block 21, a first connecting block 22 and a second connecting block 23, there are two first mounting blocks 21, and a first connecting block 22 is arranged symmetrically between the first mounting blocks 21 , the left and right sides of the first mounting block 21 are rotatably provided with rollers 20, the rollers 20 cooperate with the base 1, and the top of the first mounting block 21 on the rear side is provided with a second connecting block 23.

[0035] Planing hole mechanism 3 comprises rotating shaft 30, rotating block 31, transmission assembly 32 and baffle plate 33, and rotating type is provided with rotating shaf...

Embodiment 2

[0038] On the basis of Example 1, such as Figure 4 , Figure 5 , Figure 6 , Figure 7 , Figure 8 , Figure 9 , Figure 10 , Figure 11 and Figure 12 As shown, a booster mechanism 4 is also included, and the booster mechanism 4 includes a second mounting block 40, a biaxial motor 41, a first gear 42 and a second gear 43, and a second mounting block is provided between the rear sides of the first connecting block 22. Block 40, the middle part of the second mounting block 40 is provided with a biaxial motor 41, the left and right sides of the output shaft of the biaxial motor 41 are provided with a first gear 42, and the inner side of the rear side roller 20 is provided with a second gear 43, and the same side is equipped with a second gear 43. The first gear 42 and the second gear 43 mesh with each other.

[0039] People start the biaxial motor 41, the output shaft of the biaxial motor 41 will drive the first gear 42 to rotate, the first gear 42 will drive the second...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com