Monitoring method of welding device

A technology for welding devices and welding points, applied in auxiliary devices, welding equipment, auxiliary welding equipment, etc., can solve the problem of poor real-time detection of welding temperature, failure to detect the position of welding workpieces on both sides of the weld, and the inability to realize the fusion of hot-melt welding materials and Weld fullness and other issues to achieve the effect of ensuring fullness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0056] In order to more clearly and clearly illustrate the specific implementation purpose and implementation manner of the present invention, the technical solutions of the present invention will be fully described below, and the described embodiments are a part of the embodiments of the present invention, rather than all the embodiments. On the premise that no creative work is made, all other embodiments based on the described embodiments of the present invention belong to the protection scope of the present invention.

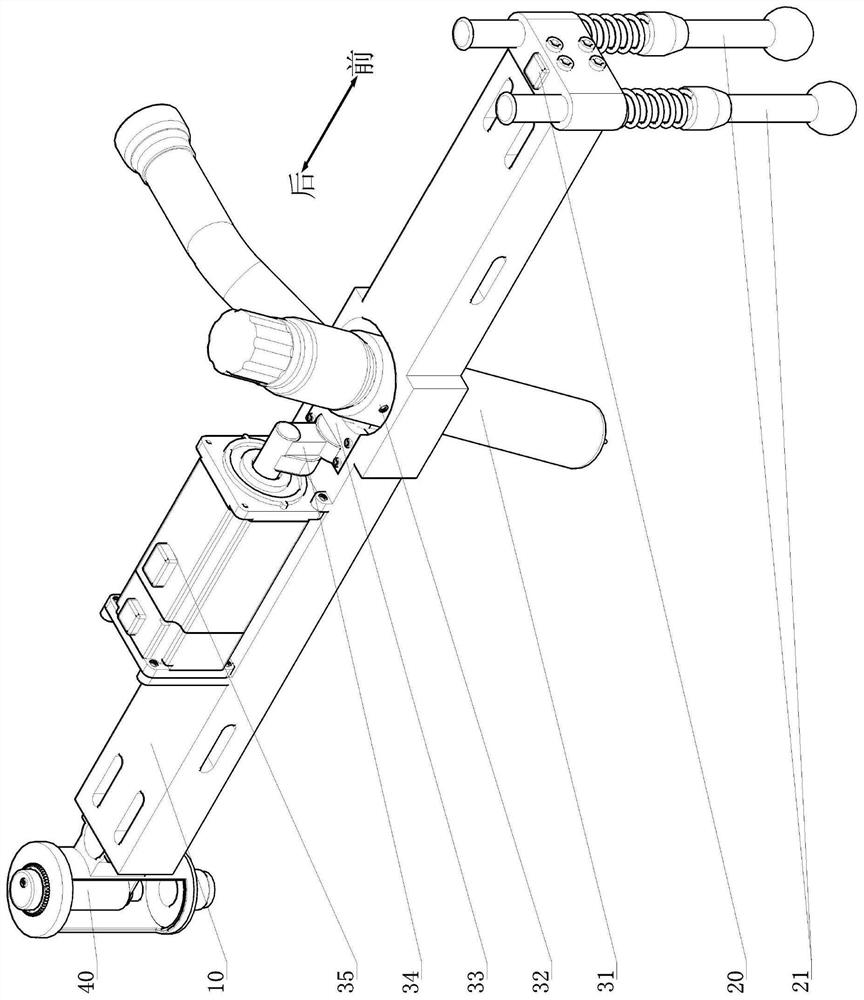

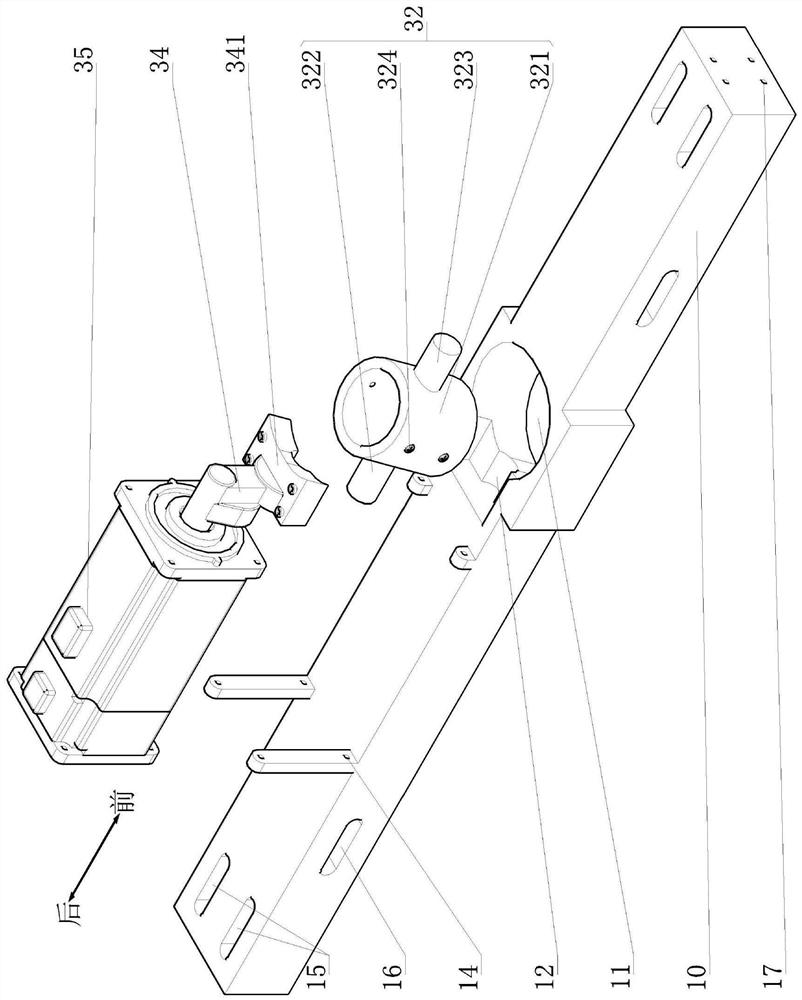

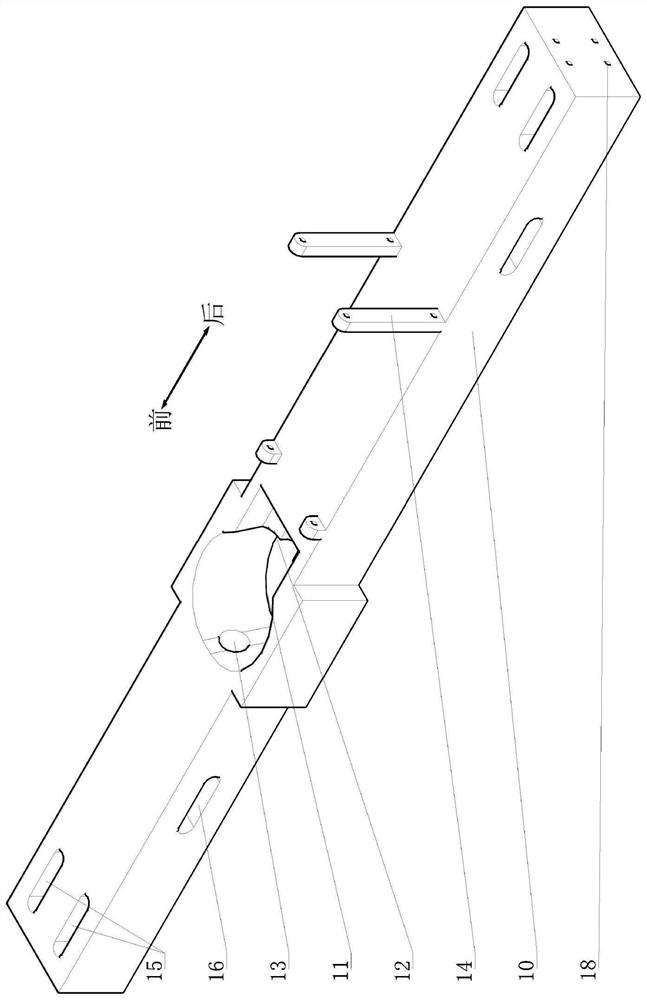

[0057] The present invention is a monitoring device for a welding device, such as figure 1 , figure 2 , image 3As shown, it includes a fixing arm 10 to be fixed on the welding device, the middle part of the fixing arm 10 is provided with a through slot 11 along the up-down direction, and the fixing arm 10 behind the through slot 11 is provided with a clamping slot 12, The fixed arm 10 in front of the through slot 11 is provided with a horizontal screw ho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com