Axial flow compressor S2 inverse problem design method based on dimensionless load control parameters

An axial flow compressor, dimensionless parameter technology, applied in computer-aided design, design optimization/simulation, calculation, etc., can solve the problem of space load matching design axial flow compressor S2 inverse problem, shorten the design cycle, improve the The effect of aerodynamic design accuracy and aerodynamic performance improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention is described in more detail below in conjunction with accompanying drawing example:

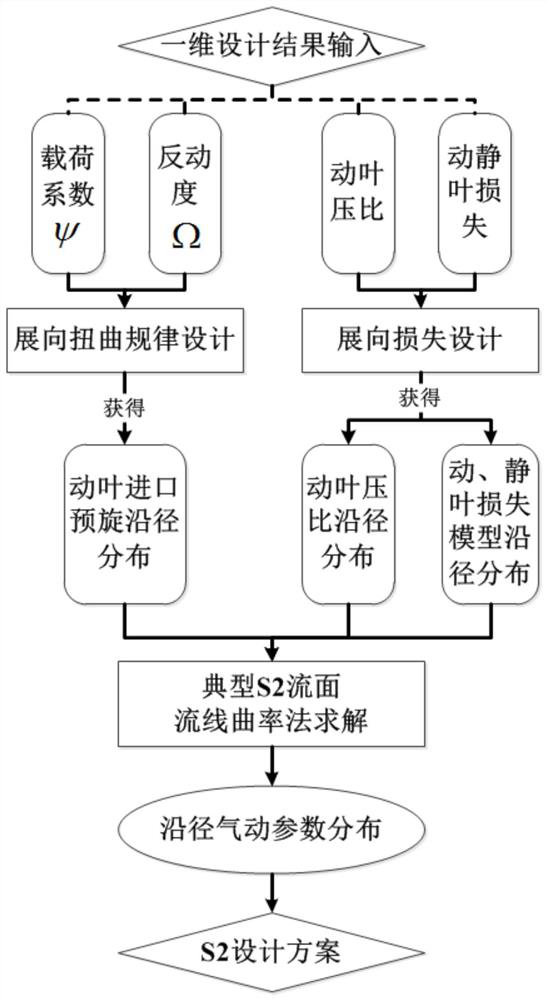

[0029] combine figure 1 , a kind of axial flow compressor S2 inverse problem design method based on dimensionless load control parameters of the present invention is realized through the following steps:

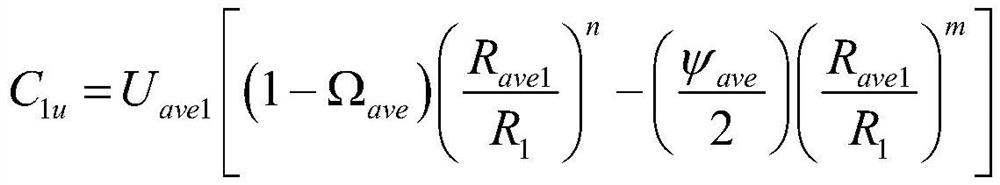

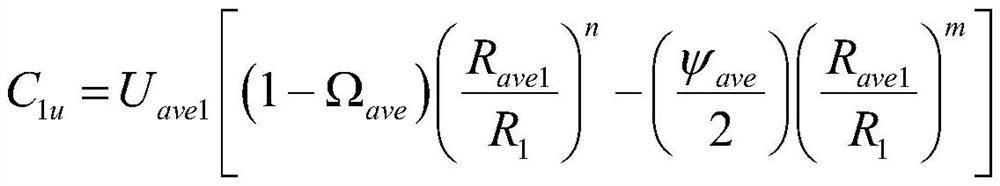

[0030] Step 1: Design the spanwise twisting law. Two dimensionless parameters, load coefficient ψ and reaction degree Ω, are used as load control parameters. The load coefficient ψ and the reaction degree Ω pass through the circumferential speed U of the rotor blade and the absolute tangential speed C of the inlet and outlet of the rotor blade 1u and C 2u Calculation:

[0031] Load factor: A dimensionless parameter characterizing the load capacity of an axial compressor stage;

[0032] reactionary degree: It is a dimensionless parameter that characterizes the load distribution between moving and stationary blades in an axial flow compressor stage.

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com