Method for operating an elevator system comprising a specification of a predetermined travel route, elevator system, and elevator controller for carrying out such a method

A technology for elevator systems and driving routes, applied in the field of elevator controllers and elevator systems, capable of solving the problems of increased number of errors, increased complexity of operation and use, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

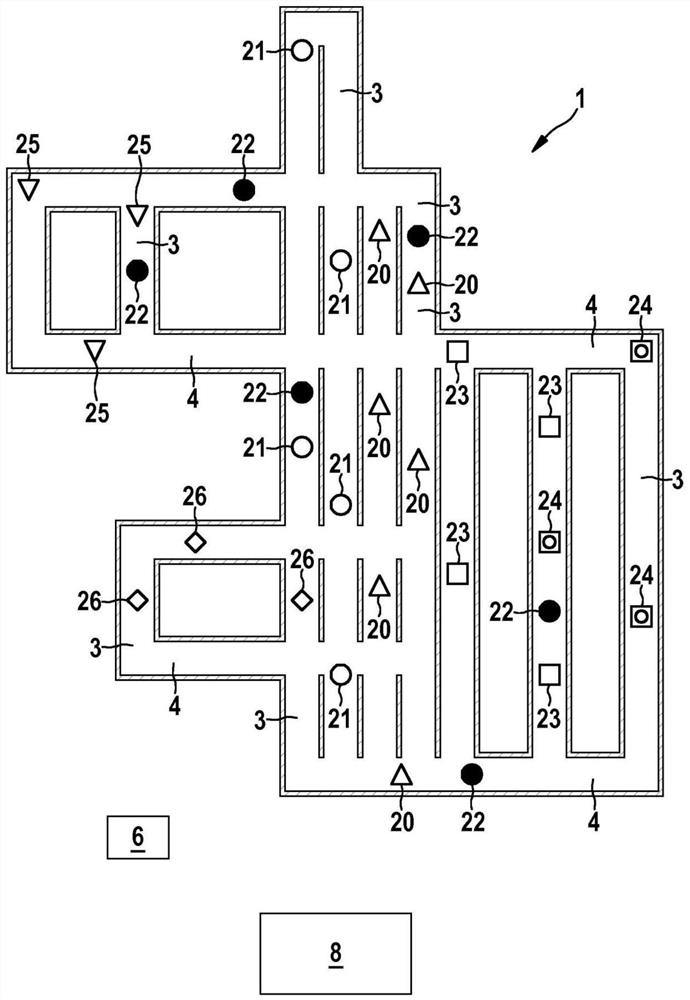

[0041] exist Figure 1a In , an elevator system 1 shown as an exemplary embodiment comprises a hoistway system having a plurality of vertical elevator shafts 3 and horizontal elevator shafts 4 . Furthermore, the elevator system 1 comprises a plurality of elevator cars 20 , 21 , 22 , 23 , 24 , 25 , 26 . Here, the elevator cars 20 , 21 , 22 , 23 , 24 , 25 , 26 of the elevator system 1 can move independently in the elevator shafts 3 , 4 . In particular it is provided that the elevator cars 20 , 21 , 22 , 23 , 24 , 25 , 26 are moved in the elevator shafts 3 , 4 by means of a linear motor drive system. Here, it is in particular provided that the elevator cars 20 , 21 , 22 , 23 , 24 , 25 , 26 can be changed from one elevator shaft 3 , 4 into the other elevator shaft 3 , 4 . For this purpose, a so-called hoistway change unit is specially provided, which Figure 1a not explicitly shown in. Furthermore, the elevator system 1 comprises an elevator controller 6, which in Figure 1a is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com