An all-in-one machine for concrete pouring and vibrating for bridge piers

A technology of concrete and all-in-one machine, applied in the direction of bridges, bridge construction, bridge parts, etc., can solve the problems of time-consuming and laborious disassembly and assembly, increase construction costs, and cannot adjust the position, and achieve convenient adjustment, reduce construction costs, and reduce construction workload. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

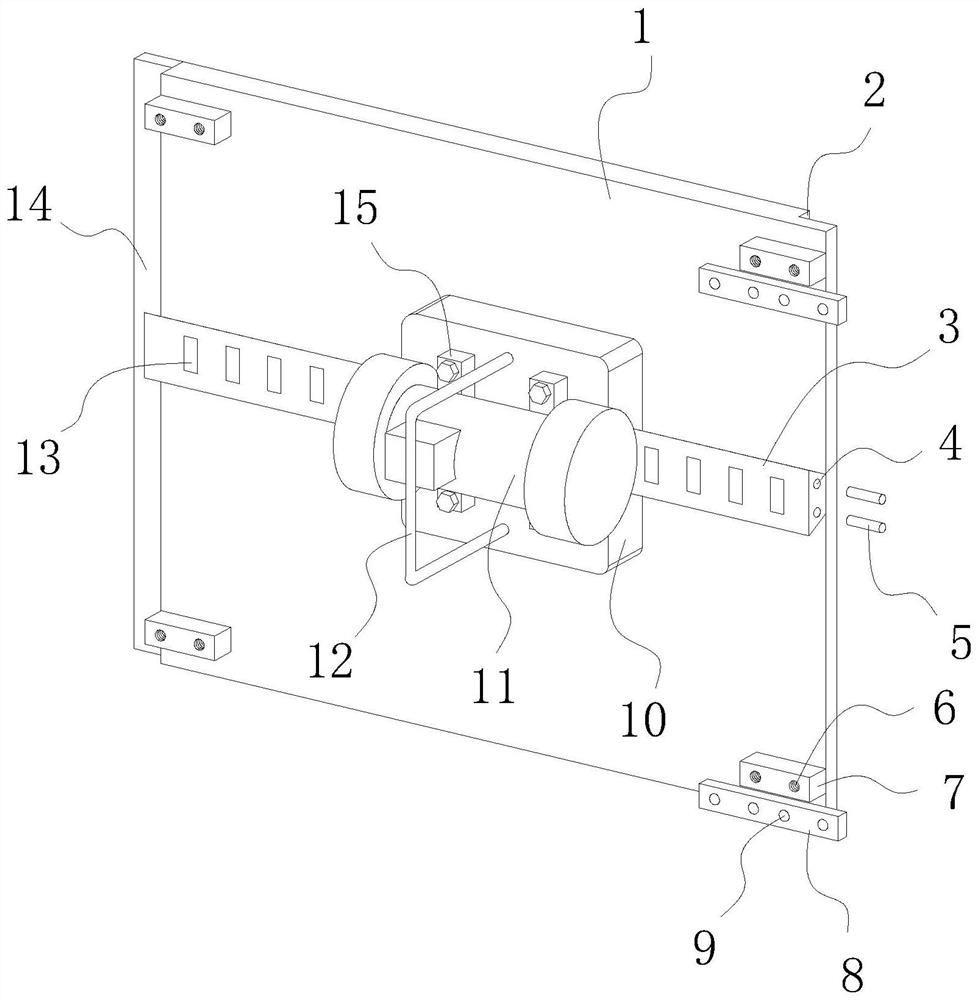

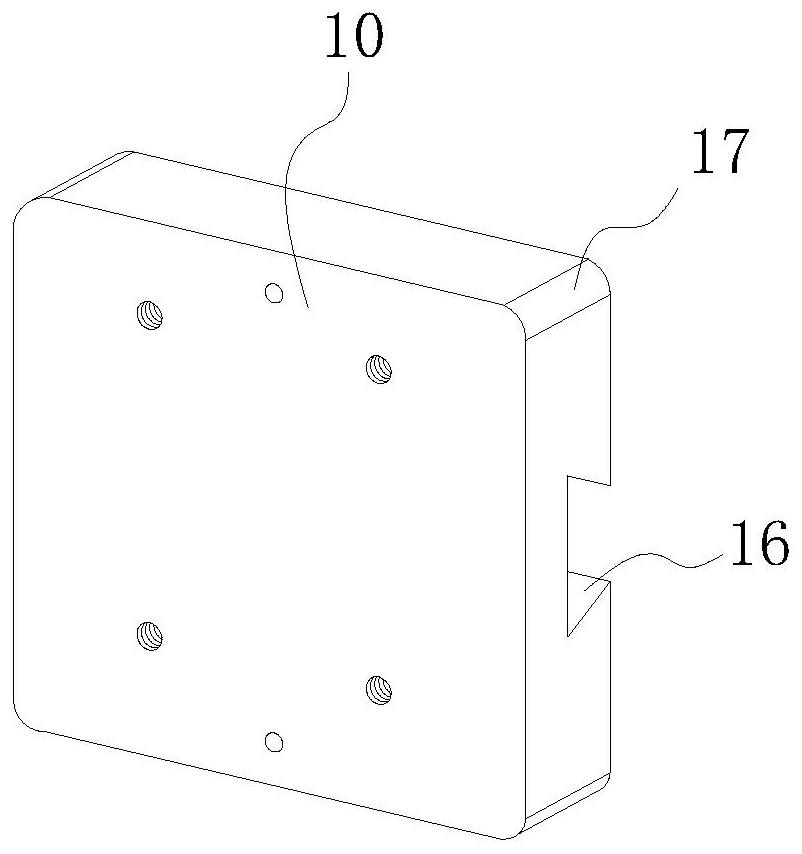

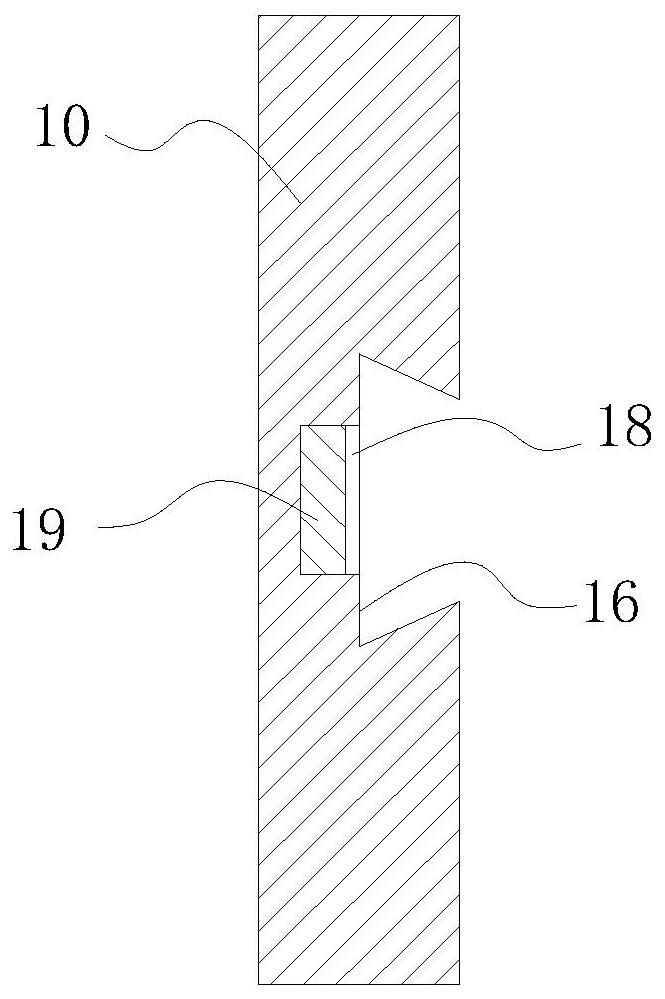

[0039] Specific implementation method: insert the dovetail tenon strip 3 on the concrete formwork 1 into the dovetail tenon groove 16 on the sliding plate 10, and install the vibration motor 11 on the sliding plate 10 to realize the plugging of the vibration motor 11 and the concrete formwork 1 , adjust the position of the vibrating motor 11 along the dovetail tenons 3, realize the convenient adjustment of the relative position of the vibrating motor 11 and the concrete formwork 1, without adopting the method of arranging multiple vibrating motors 11 on the concrete formwork 1, which is conducive to reducing the construction workload , reduce construction costs.

[0040] Several ash storage holes 20 are evenly opened on the dovetail tenon bar 3, and then the sliding plate 10 enters the dust and other small debris in the dovetail tenon groove 16 during the sliding process, and then the sliding plate 10 is extruded into the ash storage holes 20, Thereby, the purpose of temporari...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com