A kind of aftertreatment temperature control device and method for diesel engine-in-the-loop

A temperature control device, diesel engine technology, applied in the direction of engine testing, measuring device, machine/structural component testing, etc., can solve problems such as EIL test deviation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0097] The best implementation is as follows:

[0098] Control according to the target speed:

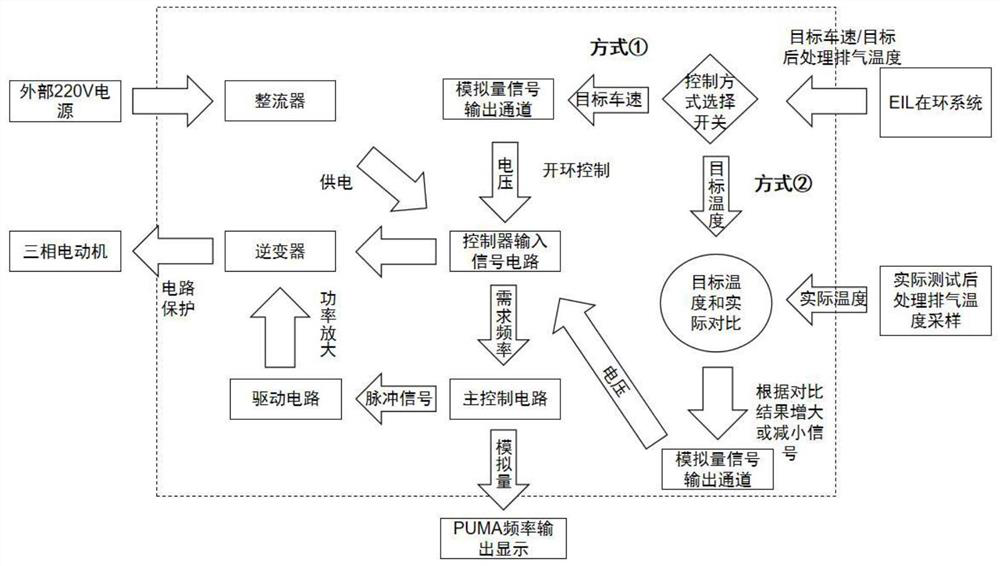

[0099] 1. Test the wind blowing through the windward facing exhaust pipe and after-treatment system at different vehicle speeds during the taxiing process of a similar vehicle (for taxiing standards, refer to Appendix C of GBT 27840-2011).

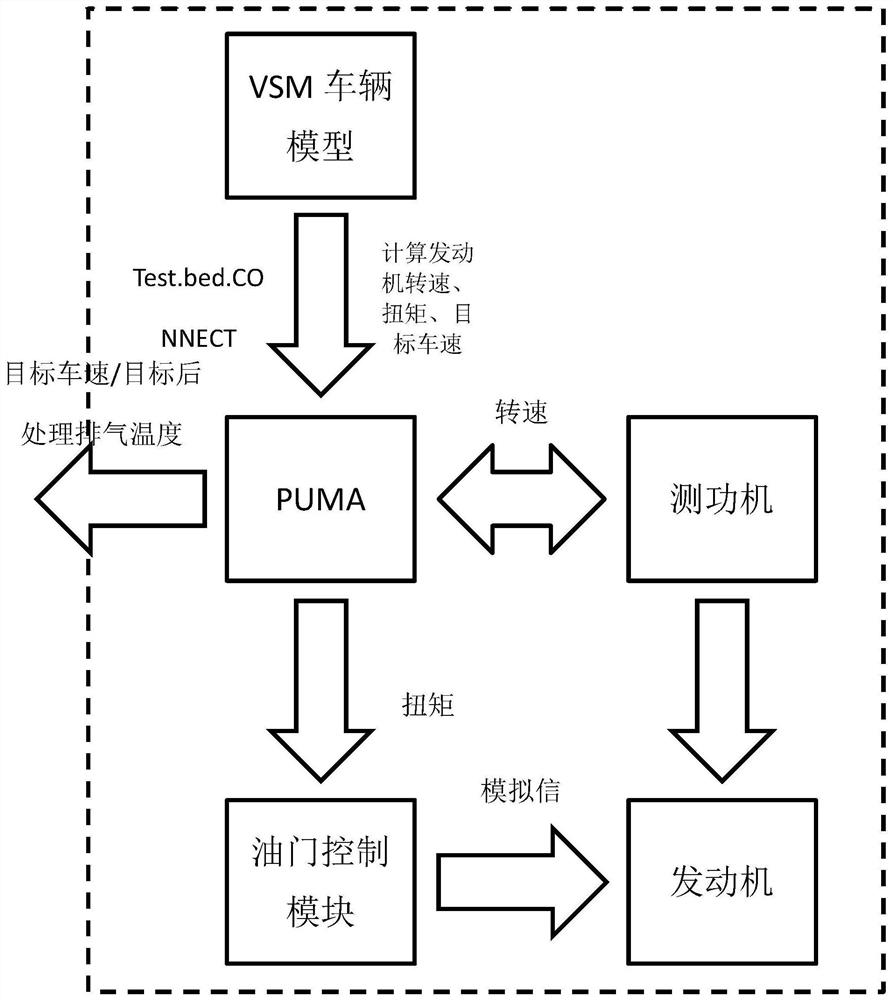

[0100] 2. Build the vehicle model and driver model in the EIL system.

[0101] 3. Select the target vehicle speed control method in the post-processing temperature control device, modify the program formula of the fan control on the bench according to the air volume tested by the whole vehicle, and realize the simulation of the wind blowing of the post-processing system when the whole vehicle is driving on the bench. .

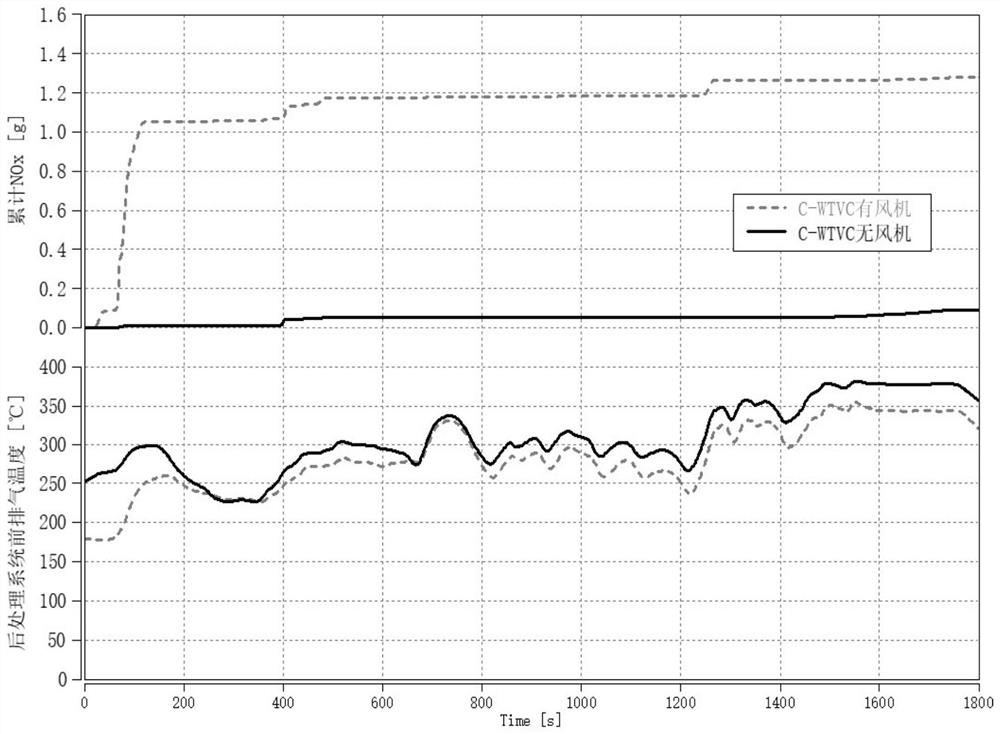

[0102] 4. While keeping the fan to follow the target speed change, combine the EIL system on the engine bench to test the vehicle operating conditions (C-WTVC, Chinese operating conditions, PEMS, etc.).

[0103] 5. Increasing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com