The moving contact supply device of the motor starter protector moving contact welding machine

A technology of starter protector and supply device, which is applied to welding equipment, auxiliary devices, auxiliary welding equipment and other directions, can solve the problems of inability to operate, difficult positioning and correspondence, and difficulty in starting the protector moving contact welding machine. The effect of reducing work intensity, saving labor resources, and good relay conveying effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In order to be able to understand the technical essence and beneficial effects of the present invention more clearly, the applicant will describe in detail below by way of examples, but the description of the examples is not intended to limit the solution of the present invention. Equivalent transformations that are only formal but not substantial should be regarded as the scope of the technical solutions of the present invention.

[0022] In the following description, all concepts related to the directionality or orientation of up, down, left, right, front and rear are referred to unless otherwise stated or otherwise stated. figure 1 The position state is based on the reference, so it cannot be understood as a special limitation on the technical solution provided by the present invention.

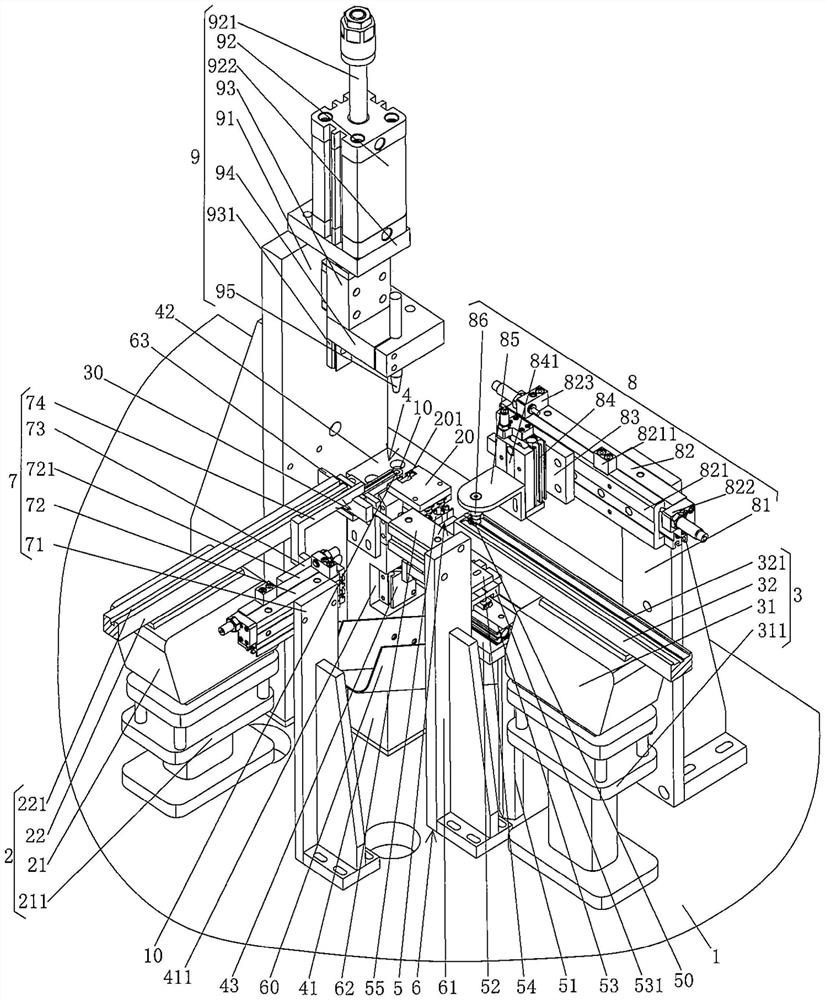

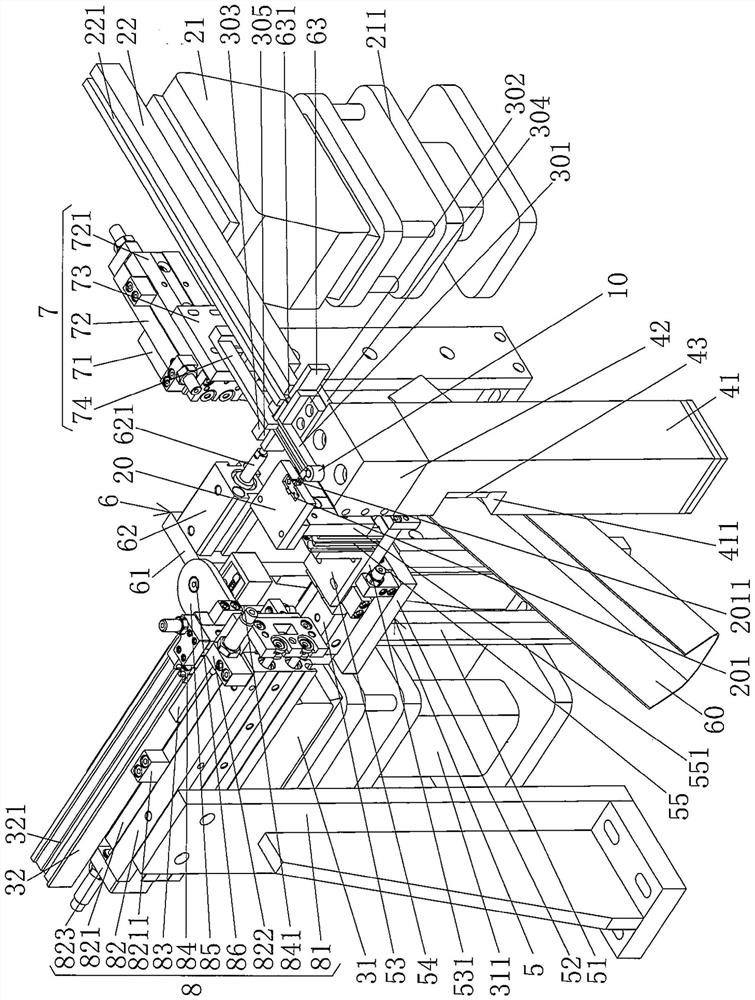

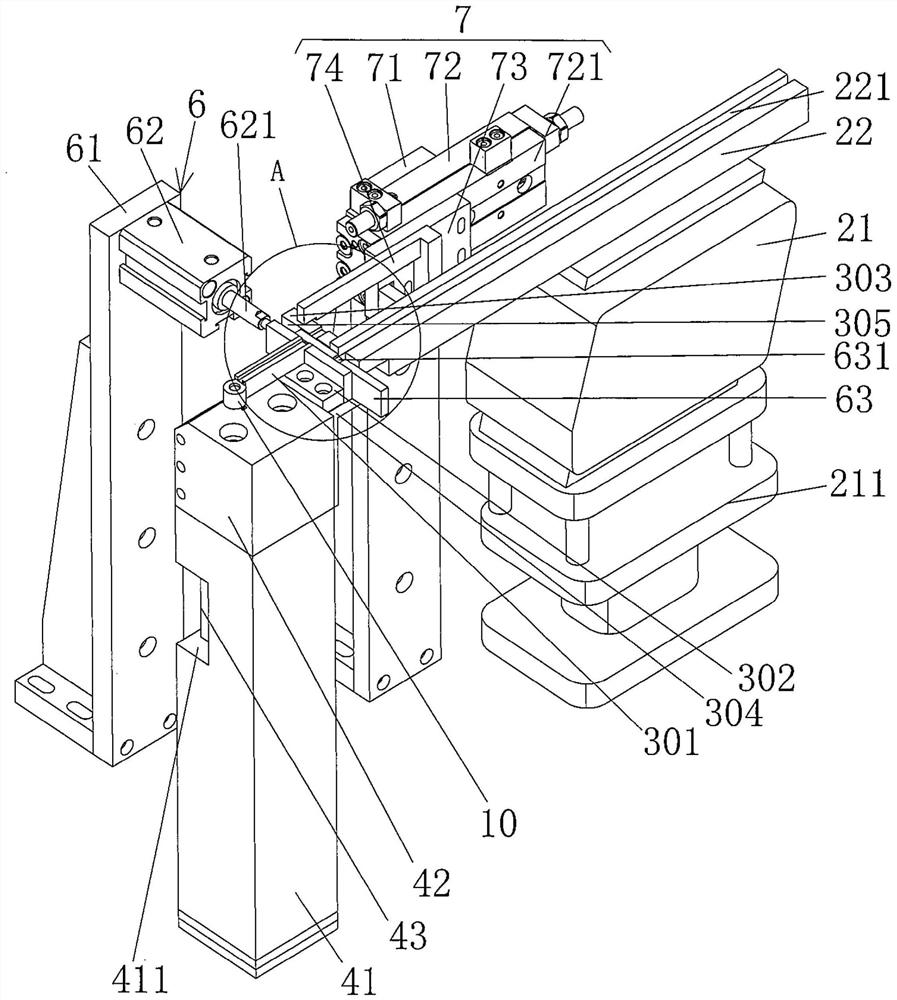

[0023] See figure 1 , showing a workbench 1, a movable contact welding die carrying mechanism 4 arranged on the workbench 1, and a movable contact welding die carrying mechanism ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com