Manipulator automatic dispensing mechanism

A technology of automatic glue dispensing and manipulator, which is applied in the direction of manipulator, smoke and dust removal, chemical instruments and methods, etc. It can solve the problems of inconvenient application and control adjustment, peculiar smell cannot be removed in real time, and affect the air quality of the working environment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

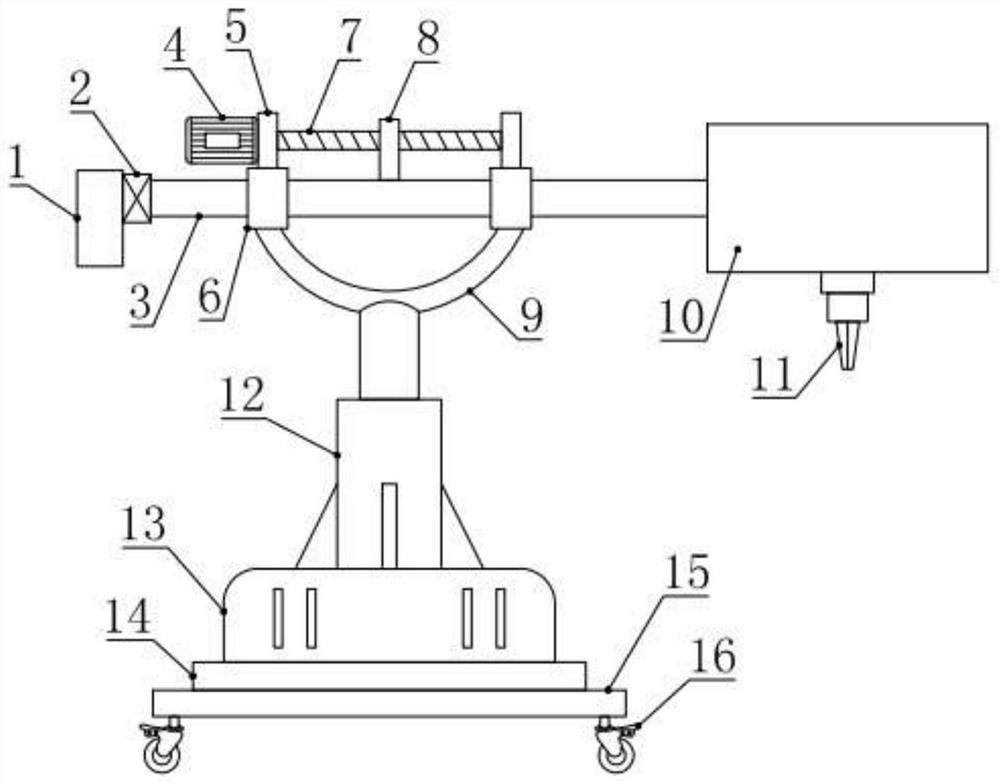

Embodiment 1

[0025] see figure 1 , in the embodiment of the present invention, an automatic dispensing mechanism of a manipulator includes a base plate base 15, a support base 14 is installed and fixed on the base base base 15, a rotary table 13 is installed on the support base 14, and the rotary table 13 can relatively support Seat 14 rotates, and the specific rotation driving structure of turntable 13 adopts the prior art and is not specifically limited; the first telescopic cylinder 12 is installed and fixed on the turntable 13, and a U-shaped cylinder is fixed on the upper end of the first telescopic cylinder 12. Bracket 9, the two ends of U-shaped brace 9 are respectively installed and fixed with a support sleeve 6, cooperate and slide in two support sleeves 6 and be provided with horizontal tube 3, also be installed on two described support sleeves 6 The drive assembly that drives the horizontal tube 3 to move along the support sleeve 6, a dispensing box 10 is installed at one end of...

Embodiment 2

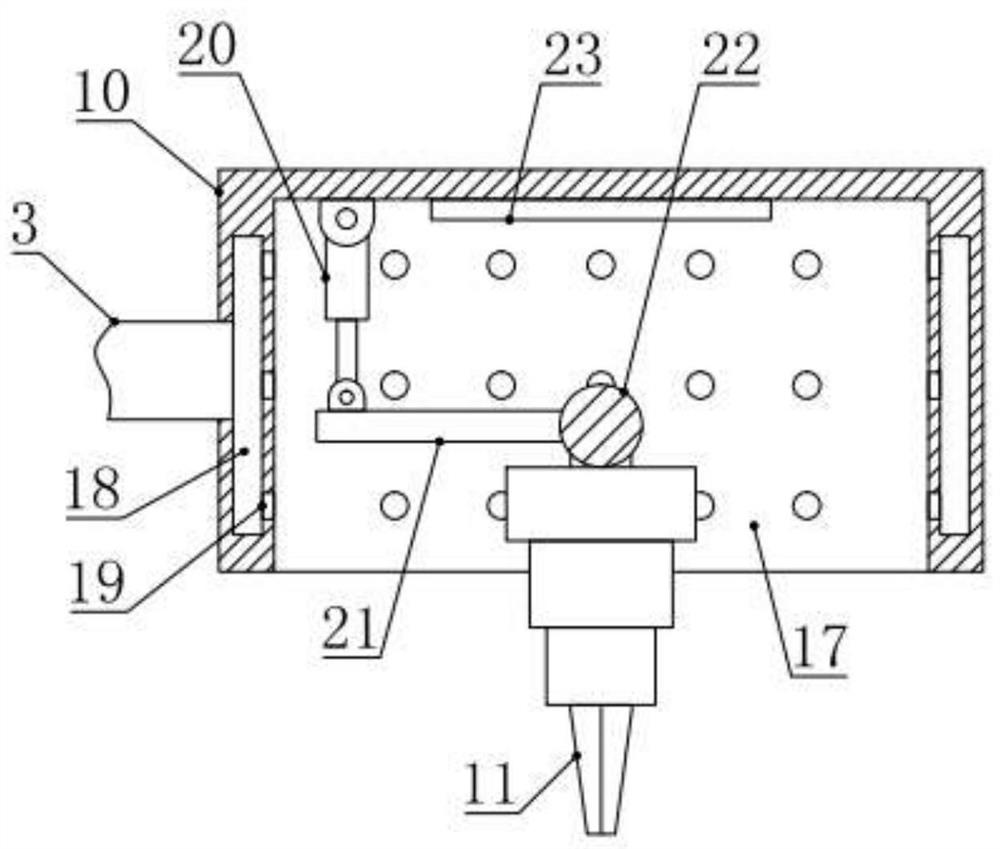

[0028] see Figure 1-4 , the difference between this embodiment and embodiment 1 is:

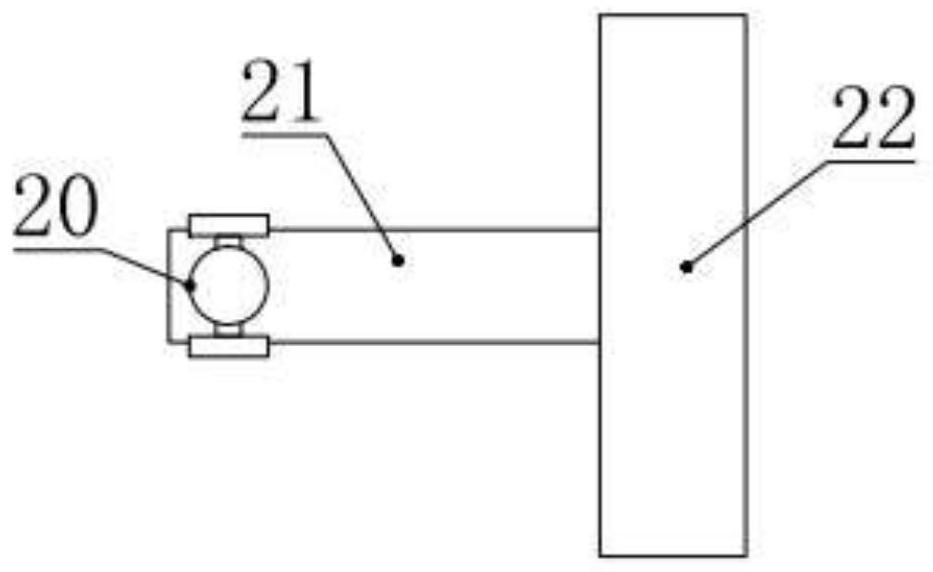

[0029] In this example, if figure 2 with 3 As shown, the dispensing box 10 is provided with an installation cavity 17 with a lower opening, and the outside of the installation cavity 17 is also provided with an annular cavity 18 in the side wall of the dispensing box 10, and one end of the horizontal tube 3 communicates with the annular cavity 18, The inner side of the annular cavity 18 is also provided with some exhaust holes 19 communicated with the installation cavity 17, through the work of the exhaust fan 2, because the horizontal pipe 3 is communicated with the exhaust holes 19 through the annular cavity 18, a negative air flow can be generated at the exhaust holes 19. The pressure can suck the peculiar smell; further, a lighting lamp 23 is also installed on the top of the installation cavity 17, and the lighting lamp 23 is used for auxiliary lighting to improve the quality of dispe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com