A kind of preparation method of FRP sand pipe

A technology of FRP with sand and glass surface, which is applied in the field of FRP pipes, can solve the problems of high production cost and large resin consumption, and achieve the effect of enhancing mechanical properties and preventing cracking and shrinkage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

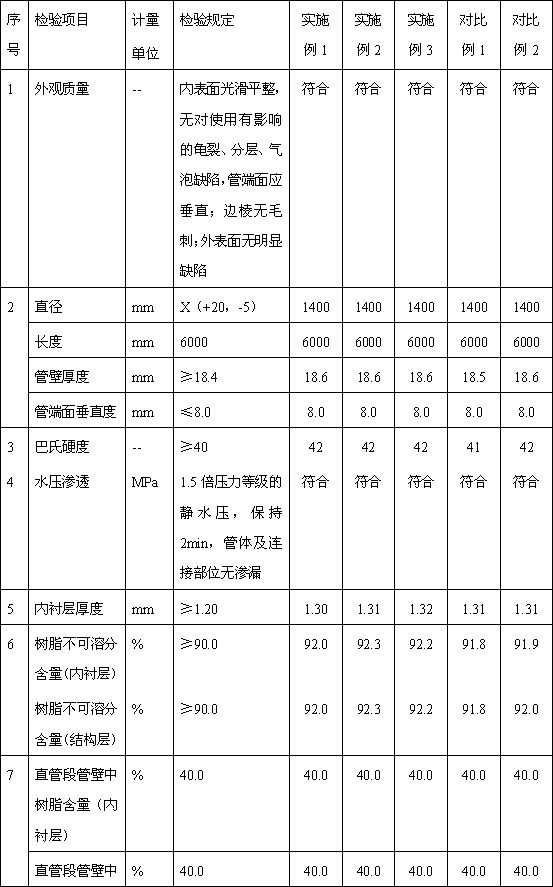

Examples

Embodiment 1

[0045] A preparation method of a glass fiber reinforced plastic sand-filled pipe, comprising the following technical steps:

[0046] 1) Lining:

[0047] Prepare materials according to the type and specifications of the designed materials. The materials should be stacked neatly, safely and cleanly, and the materials should be strictly prevented from getting wet. The storage distance of accelerators and curing agents should not be less than 5 meters;

[0048] Remove the sundries on the surface of the mold, make the outer surface of the mold smooth and smooth, check whether the mold structure is in good condition, and whether the welding seam of the shaft head is open. , the thickness is in line with the design requirements, the mold needs to be waxed once for the first time or for several consecutive uses, and the waxing frequency is increased when demolding is difficult;

[0049] Prepare 50mm specification film according to pipe diameter requirements;

[0050] Apply the film,...

Embodiment 2

[0073] A preparation method of glass fiber reinforced plastic sand-filled pipe, compared with Example 1:

[0074] In the lining production of step 1), prepare a 200mm specification film according to the pipe diameter requirements;

[0075] Described accelerator is cobalt water, curing agent is methyl ethyl ketone peroxide, resin is selected from unsaturated polyester resin, wherein inner lining resin is selected from bisphenol A type unsaturated polyester resin, accelerator, curing agent and resin The mass ratio is 0.3:3:100;

[0076] Other steps are the same as in Example 1.

Embodiment 3

[0078] A preparation method of glass fiber reinforced plastic sand-filled pipe, compared with Example 1:

[0079] In the lining production of step 1), prepare a 100mm specification film according to the pipe diameter requirements;

[0080] Described accelerator is cobalt water, curing agent is methyl ethyl ketone peroxide, resin is selected from unsaturated polyester resin, wherein inner lining resin is selected from polyester resin or vinyl ester resin, the quality of accelerator, curing agent and resin The ratio is 0.3:2.5:100;

[0081] Other steps are the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com