Assembling device and assembling method thereof

An assembly device and assembly method technology, which is applied in the field of parts assembly, can solve the problems of complex hardware and software structures of mechanical fingers and assembly fixtures, and are difficult to implement, and achieve the effect of simplifying process organization and supporting tooling and fixtures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

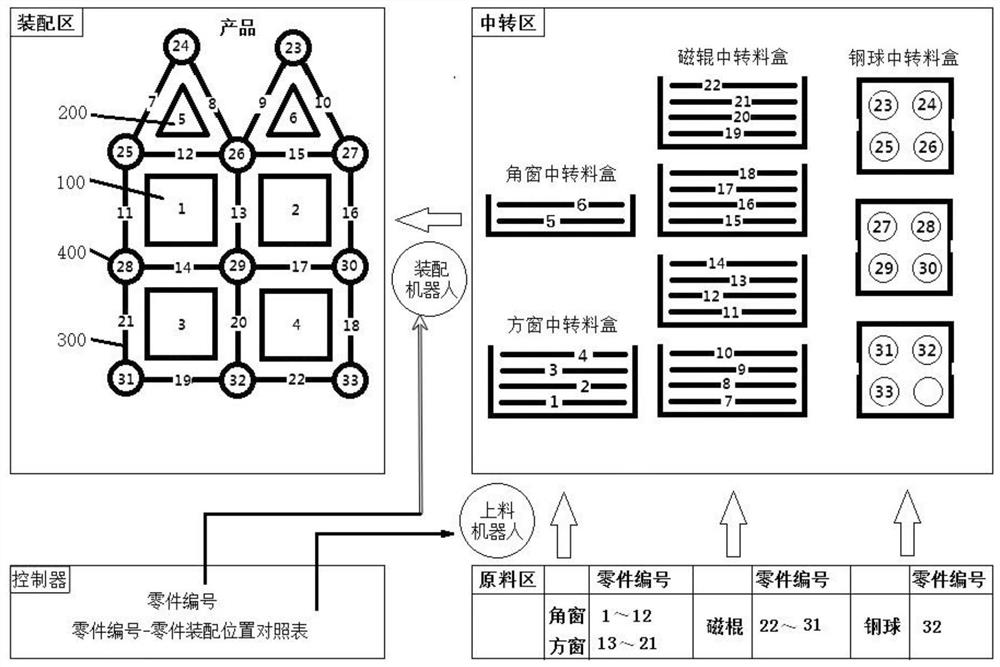

[0030] Such as figure 1 As shown, in one embodiment of the present invention, the assembly device includes a loading robot, a transfer box, an assembly robot and a controller;

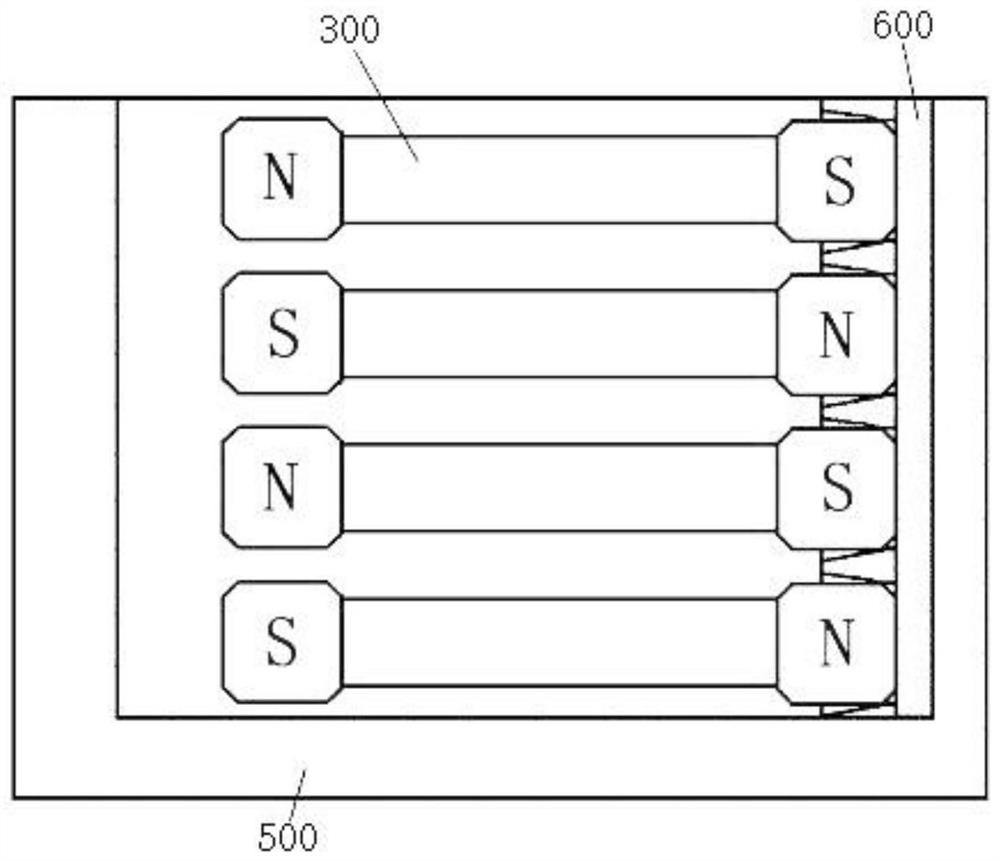

[0031] The controller is equipped with an analysis module, a material discharge control module and an assembly control module, and the analysis module is electrically or signally connected to the discharge control module and the assembly control module; the analysis module analyzes the product into parts according to the customized information, and the The assembly position is numbered, and the part number corresponding to each assembly position number is obtained, and a comparison table between the part number and the part assembly position number is established. The analysis module is also equipped with a basic information sub-module and an input sub-module. The basic information sub-module and the Analysis module electrical connection or signal connection, one or more sets of product assembly models...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com