Satellite assembly process reconstruction system and method based on multiple assembly sequences

An assembly process and assembly sequence technology, which is applied in manufacturing computing systems, instruments, data processing applications, etc., can solve the problems of incomplete materials at the satellite assembly site, long temporary repair period, etc., and achieve the effect of supporting the flexibility of process switching

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

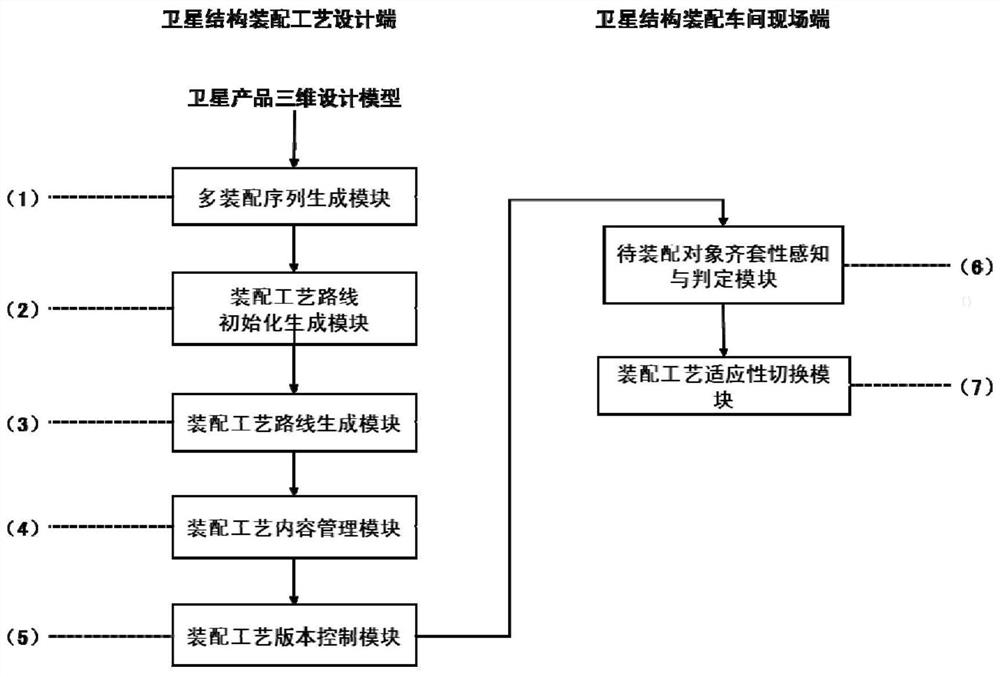

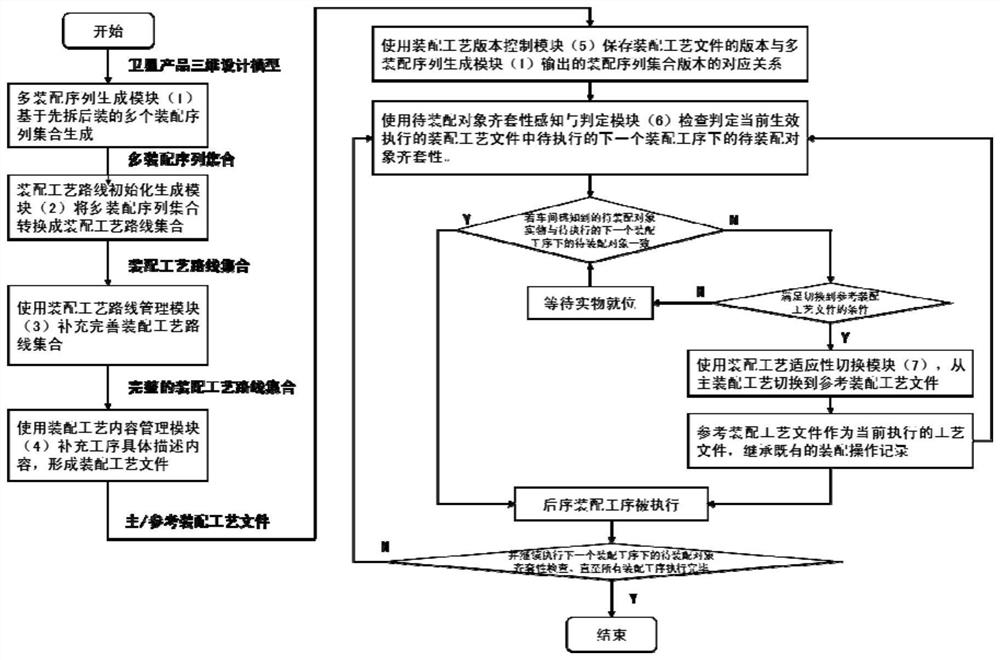

[0035] Such as figure 1 and figure 2 As shown, a satellite assembly process rapid reconfiguration system based on multiple assembly sequences, the system includes multiple assembly sequence generation module (1), assembly process route initialization generation module (2), assembly process route generation module (3), assembly Process content management module (4), assembly process version control module (5), completeness perception and judgment module of objects to be assembled (6), assembly process adaptability switching module (7).

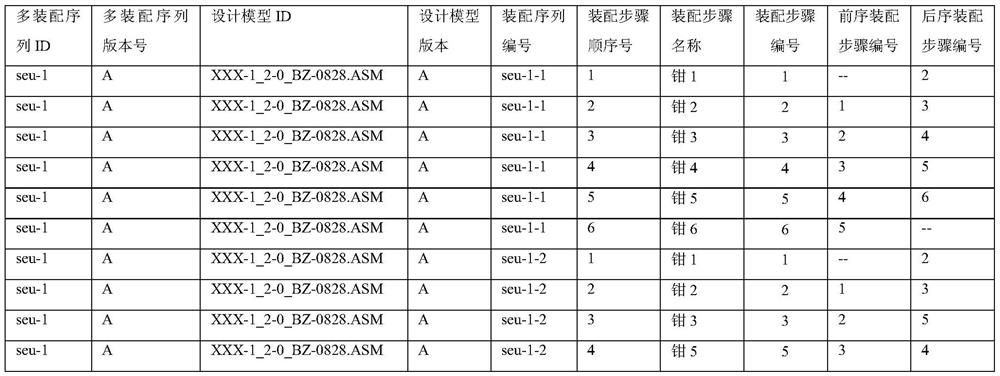

[0036] The multi-assembly sequence generation module (1) is used to analyze the PROE-based 3D design model XXX-1_2-0_BZ-0828.ASM of satellite products, and obtain all feasible assembly sequence sets of satellite products based on the assembly sequence generation method of first disassembly and then assembly SEU={seu-1}, the assembly sequence set includes multiple assembly sequence ID=seu-1, multiple assembly sequence version number=A, assembl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com