Building construction formwork convenient to disassemble

A technology that facilitates building construction and disassembly. It is applied in the direction of construction, building structure, formwork/formwork/work frame, etc. It can solve the problems of wasting materials, limited single angle, wasting manpower, etc., and achieves long service life and simple operation. , The effect of saving materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

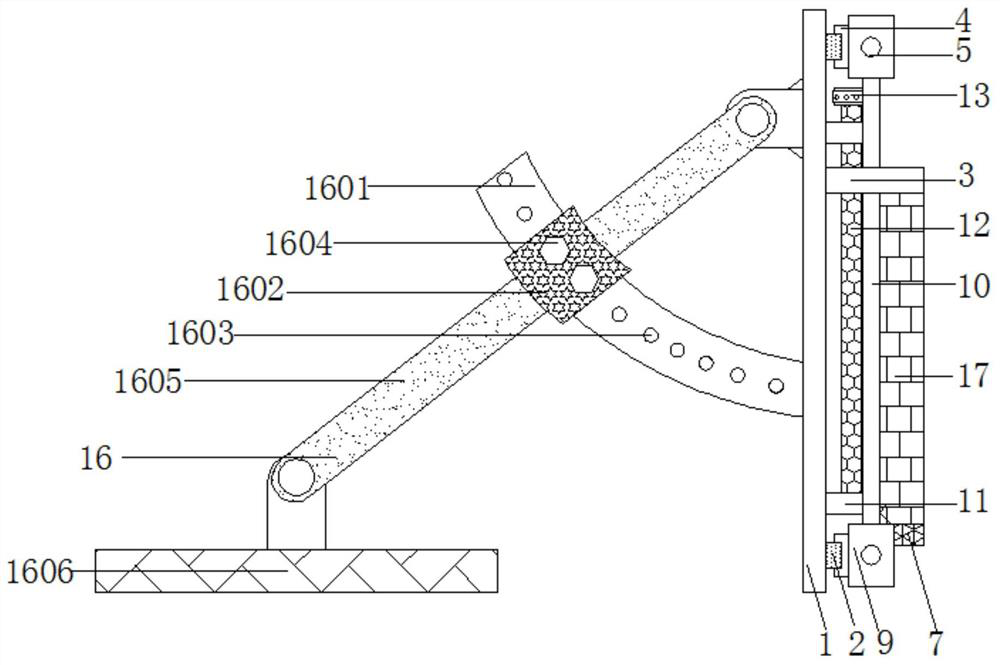

[0025] Such as figure 1 As shown, the template for building construction that is easy to disassemble includes a base 1 and an adjustment mechanism 16. The adjustment mechanism 16 includes an arc-shaped slide plate 1601, an arc-shaped chute 1602, a second threaded hole 1603, a bolt 1604, a connecting rod 1605 and a support 1606 The bottom of the outer wall on the left side of the base 1 is fixedly connected with an arc-shaped slide plate 1601, the left end of the arc-shaped slide plate 1601 is sleeved with an arc-shaped chute 1602, and the upper and lower outer walls of the arc-shaped chute 1602 are fixedly connected with a connecting rod 1605, and the connecting rod 1605 points The upper and lower parts are fixedly connected with the arc chute 1602, the top of the connecting rod 1605 is connected to the left outer wall of the base 1 through the rotating shaft, and the bottom end of the connecting rod 1605 is connected with the support 1606 through the rotating shaft; A number ...

Embodiment 2

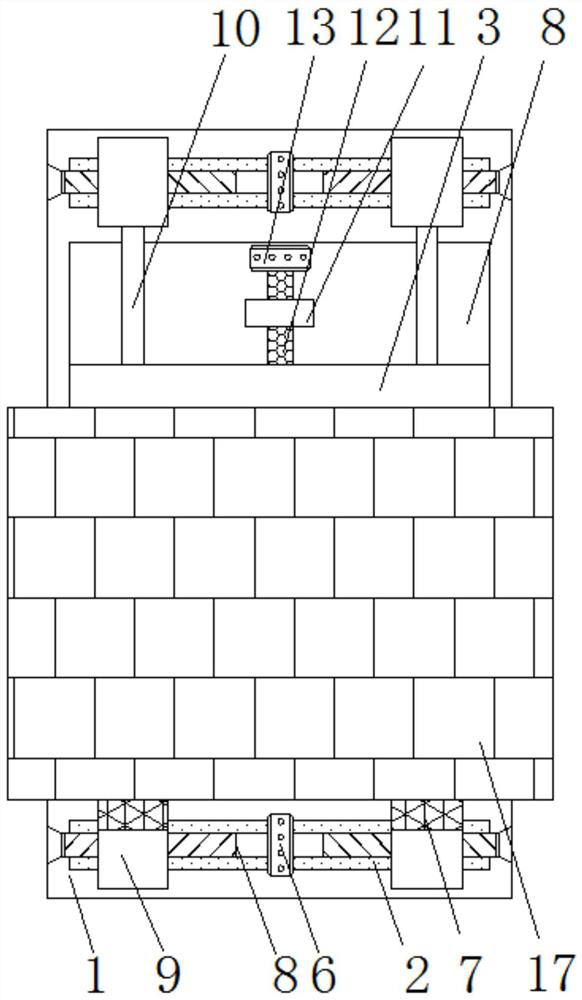

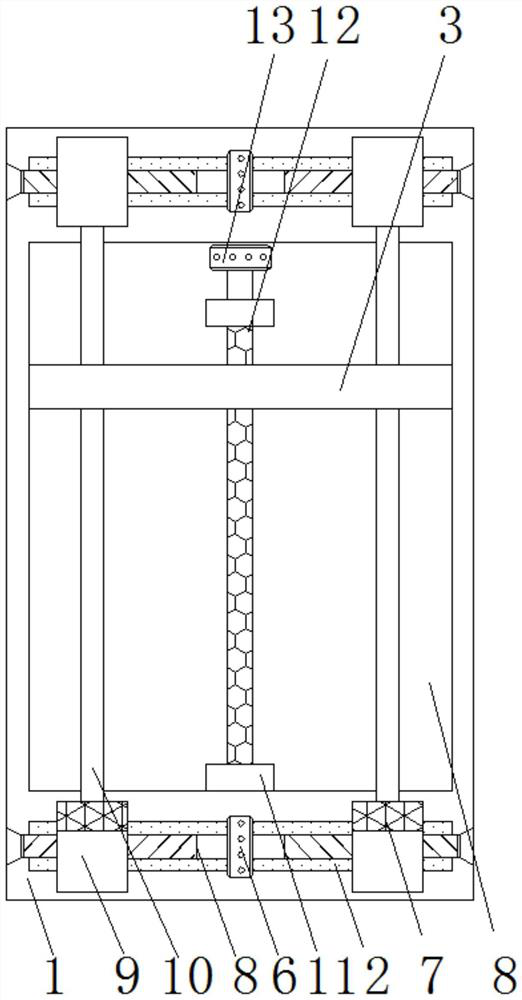

[0028] Such as Figure 1-4 As shown in the template for building construction that is easy to disassemble, the upper and lower ends of the base 1 are fixedly connected to the slide rail 2, the left and right ends of the slide rail 2 are slidably connected to the slider 4, and the outer wall of the slider 4 is fixedly connected to the block 9. A splint 7 is fixedly connected above the outer walls of two groups of squares 9, a major axis 10 is fixedly connected between each group of vertical squares 9, and a first screw rod 5 runs through and connected between each two groups of horizontal squares 9. The upper and lower ends of a screw rod 5 run through and pass through the middle of the block 9, and the middle end is provided with a first adjustment handle 6; the top of the base 1 is slidably connected with a moving plate 3, and the left and right ends of the moving plate 3 are connected to the long axis 10 Through the connection, and the middle end is connected with the second...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com