A mobile garbage disposal system and method using a gas-powered vehicle

A technology of waste treatment system and flue gas treatment system, which is applied in combustion methods, combustion product treatment, motor vehicles, etc., to achieve the effects of reducing operating costs, shortening warm-up time, and reducing environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

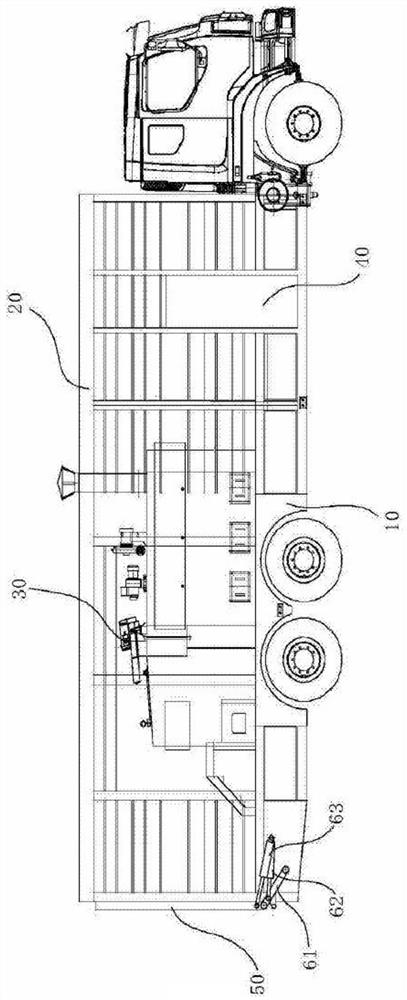

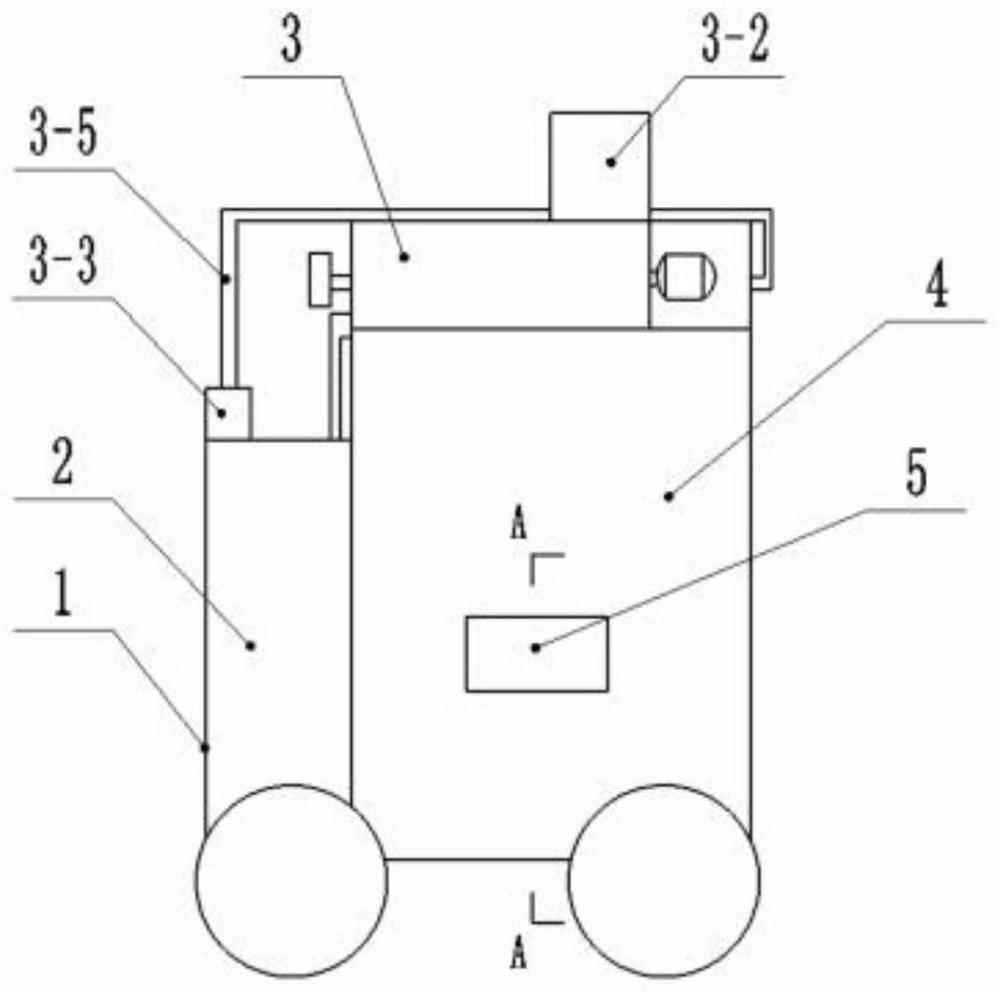

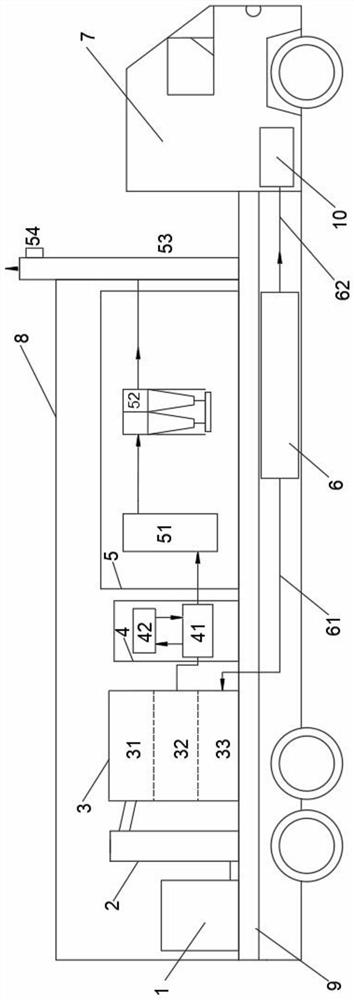

[0030] The mobile garbage disposal system adopting gas-powered automobile of the present invention, as image 3 As shown, it includes a pulverizer 1, a lifting device 2, a three-stage garbage incinerator 3, a flue gas cooling system 4, a flue gas treatment system 5, a gas storage tank 6, a car body 7, a container 8 and a placement plate 9. Wherein, the three-stage garbage incinerator 3 includes a drying bin 31, a pyrolysis bin 32, and a combustion bin 33; the flue gas cooling system 4 includes a heat exchanger 41 and a cooling liquid circulation system 42; the flue gas treatment System 5 includes acid removal device 51, bag filter 52, chimney 53 and flue gas online monitoring system 54; the pulverizer 1, lifting device 2, three-stage garbage incinerator 3, flue gas cooling system 4, flue gas treatment The system 5, the gas storage tank 6 and the container 8 are all fixedly installed on the placement plate 9.

[0031]During operation, a large amount of rubbish and ash produced...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com