An elevator lifting safety operation system

A technology for safe operation and elevators, applied in elevators, elevators in buildings, transportation and packaging, etc., can solve the problems of no vertical anti-pinch protection device, serious casualties, hidden safety hazards, etc., to achieve good teaching effect and guarantee Safety of life and effect of improving safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

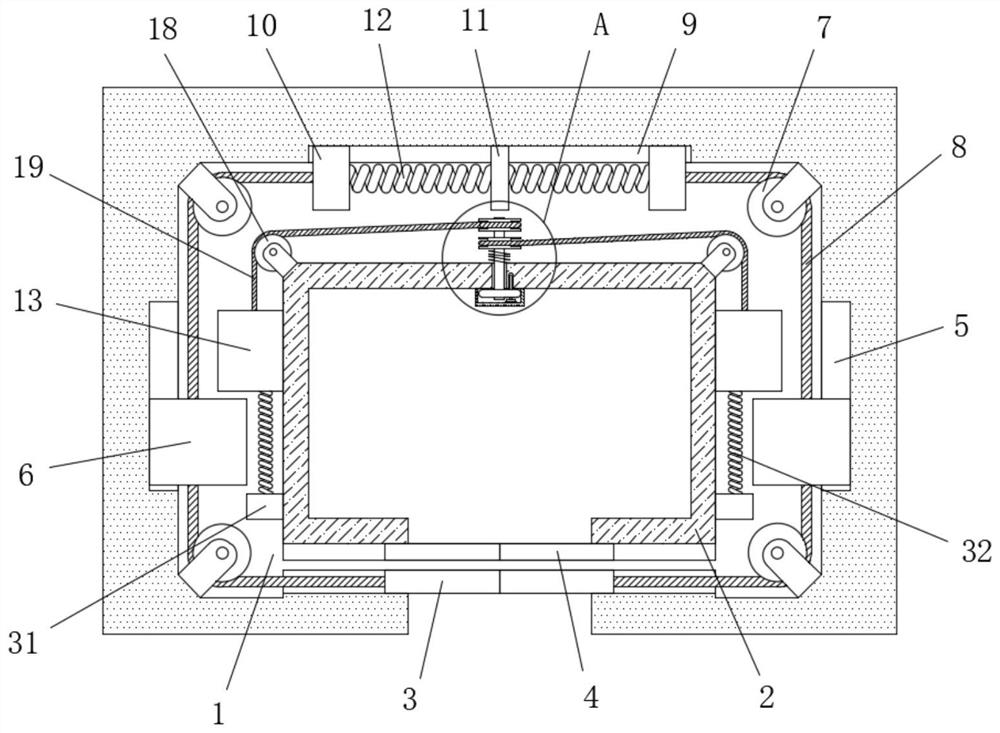

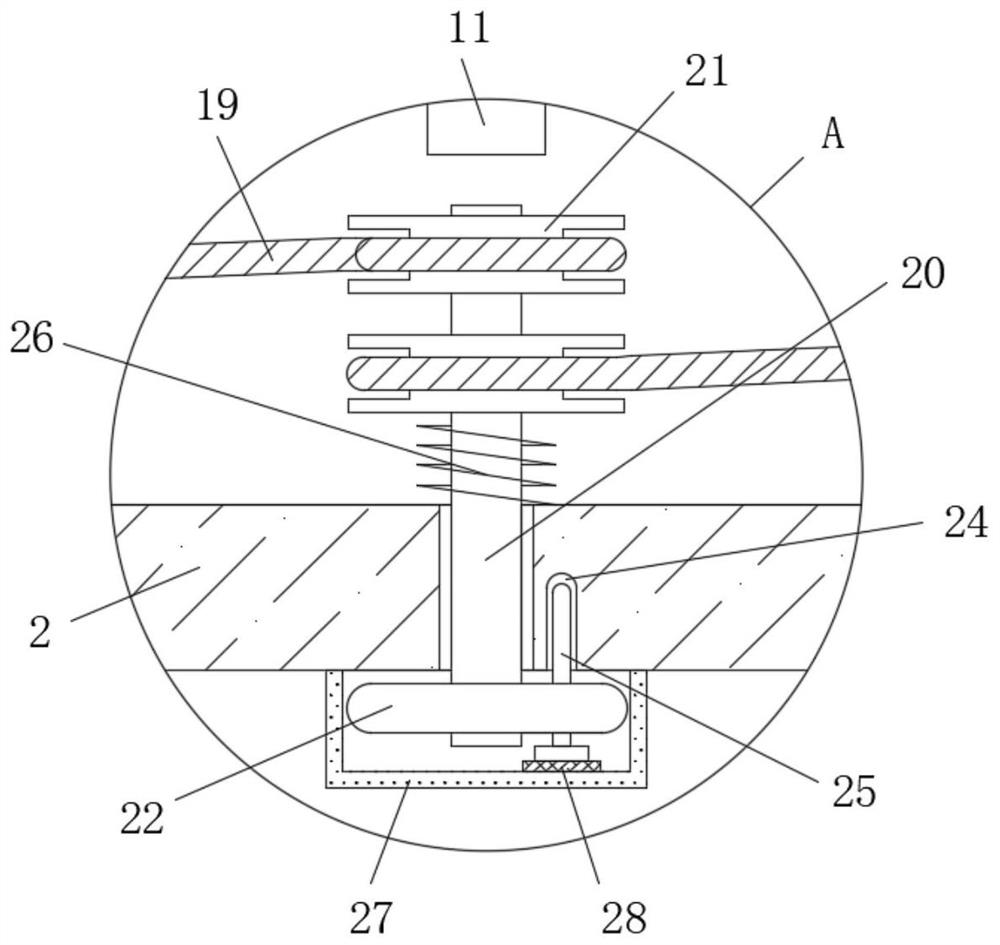

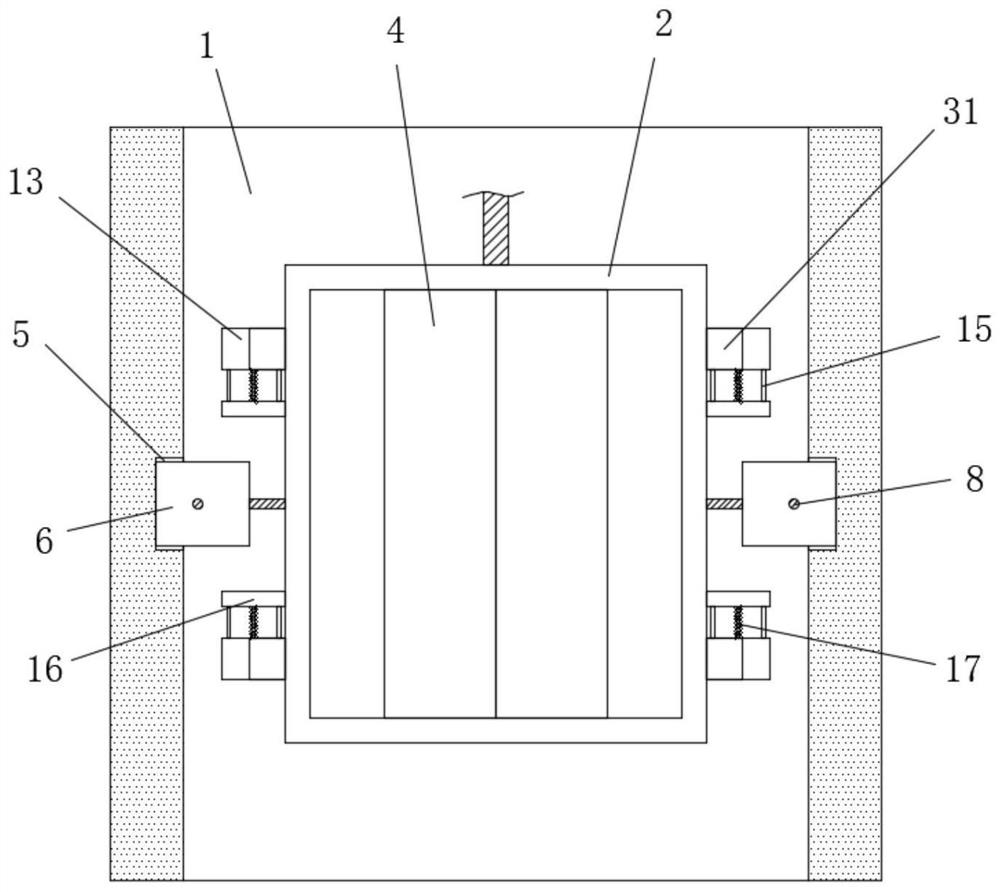

[0032] Refer Figure 1-9An elevator lifting and landing safety operation system includes a lift connection to the car 2 in the wellway 1, and one side of the wellway 1 is provided with a door door 3, and the side of the car 2 is provided with a parallel door 4 corresponding to the layer door 3. The inner wall of the wellway 1 is asymmetrically disposed with two first slide 5, and the two first slots 5 are symmetrically slided with two stops 6, and the two stoppers 6 are close to each other. The inside of the wellway 1 is extended, and the four corners of the inner wall of the wellway 1 are rotated, and the first guide wheel 7 is connected, and the inner wall of the outer portion of the wellway 1 away from the door 3 is provided with a second slider 9, and the second slide 9 is symmetrical. Sliding has two slider 10, and both of the two slider 10 extend to the inside of the wellway 1, and the block 6 is fixed to each other, and there is a first steel rope 8, two first steel rope 8 O...

Embodiment 2

[0034] Based on the first embodiment, the second chute 9 is fixedly connected to the first fixing block 11 between the two slider 10, and the first fixed block 11 is different from each other. A side of the block 10 is fixed to each other, and the same first tension spring 12 is attached, and the two sets of buffer components include the two sets of buffer components including the two sets of buffer assemblies. 13 The four angles of the four angles of each side is slid in the plurality of cylindrical grooves 14, and the sliding rod 15 is slidably connected, and the ends of the four sliding rods 15 on the same limit block 13 extends to the limit. The outer side of the block 13 is fixedly connected, and the same movable block 16 can be connected to the movable block 16 to a stable limit connection through the slider 15, and the movable block 16 is symmetrically fixed to each other. The buffer spring 17 can function on the movable block 16 to the cushioning movement by the buffer spr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com