Automatic test device for idling test run of water-turbine generator set

A generator set and automatic test technology, which is applied to hydroelectric power generation, measuring devices, engine components, etc., can solve the problems of large manpower input and low work efficiency, and achieve the effects of labor saving, high work efficiency and easy fixing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

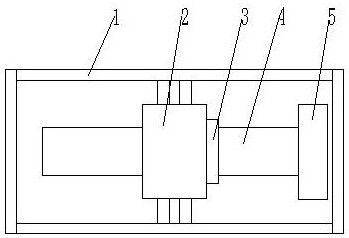

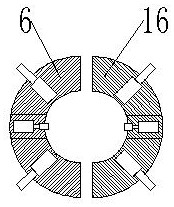

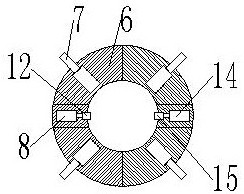

[0048] Such as Figure 1-7 As shown, an automatic test device for idling trial operation of a hydroelectric generator set; comprising a machine pit 1 and a hydroelectric generator set arranged in the machine pit 1, the hydroelectric generator set including a hydroturbine runner 5; the hydroturbine runner 5 is provided with a rotating shaft 4; the rotating shaft 4 is provided with a rotating shaft measuring device 2; the measuring device 2 is arranged at the corresponding bearing 3; the rotating shaft measuring device 2 is provided with a first electric telescopic rod 7; the rotating shaft The inner side of the measuring device 2 is provided with a second electric telescopic rod 8 and a third electric telescopic rod 14; the second electric telescopic rod 8 is provided with a dial indicator 12 on the output shaft, and the dial indicator 12 is used to measure the power generation of the water turbine. The vertical vibration data of the turbine and the generator set; the output sha...

Embodiment 2

[0057] Such as Figure 1-7 As shown, an automatic test device for idling trial operation of a hydroelectric generator set; comprising a machine pit 1 and a hydroelectric generator set arranged in the machine pit 1, the hydroelectric generator set including a hydroturbine runner 5; the hydroturbine runner 5 is provided with a rotating shaft 4; the rotating shaft 4 is provided with a rotating shaft measuring device 2; the measuring device 2 is arranged at the corresponding bearing 3; the rotating shaft measuring device 2 is provided with a first electric telescopic rod 7; the rotating shaft The inner side of the measuring device 2 is provided with a second electric telescopic rod 8 and a third electric telescopic rod 14; the second electric telescopic rod 8 is provided with a dial indicator 12 on the output shaft, and the dial indicator 12 is used to measure the power generation of the water turbine. The vertical vibration data of the turbine and the generator set; the output sha...

Embodiment 3

[0072] During the experiment, in order to be able to automatically measure the bearing oil temperature, bush temperature, and shaft vibration and swing data, save labor and improve work efficiency, the present invention also discloses an automatic test for the idling test operation of a hydroelectric generator set. The method includes the following steps:

[0073] S1: Put the rotating shaft measuring device on the rotating shaft and fix it with the machine pit;

[0074] S2: Adjust the angle of the dial indicator and the rotational speed measuring instrument so that the dial indicator and the rotational speed measuring instrument are facing the axis of the shaft;

[0075] S3: The hydraulic turbine generator set slowly opens the guide vane opening to about 5%-6%. After the standby unit starts to rotate, the device will close the guide vane opening to 0%, and the unit is still in a creeping state;

[0076] S4: Data measurement, the rotating shaft measuring device measures the oil tempera...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com