An extrusion production line for pipe production

A production line and pipeline technology, applied in the field of pipeline production equipment, can solve problems such as large staff head, pipeline damage, pipeline cracks, etc., and achieve the effects of good collection, reduction of excessive deformation, and neat deformation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The following is attached Figure 1-4 The application is described in further detail.

[0035] The embodiment of the present application discloses an extrusion production line for pipeline production.

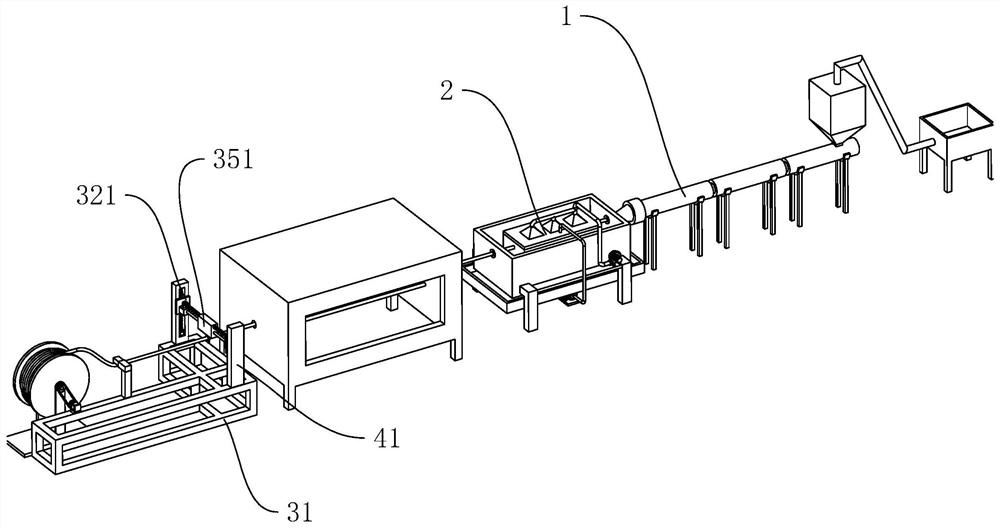

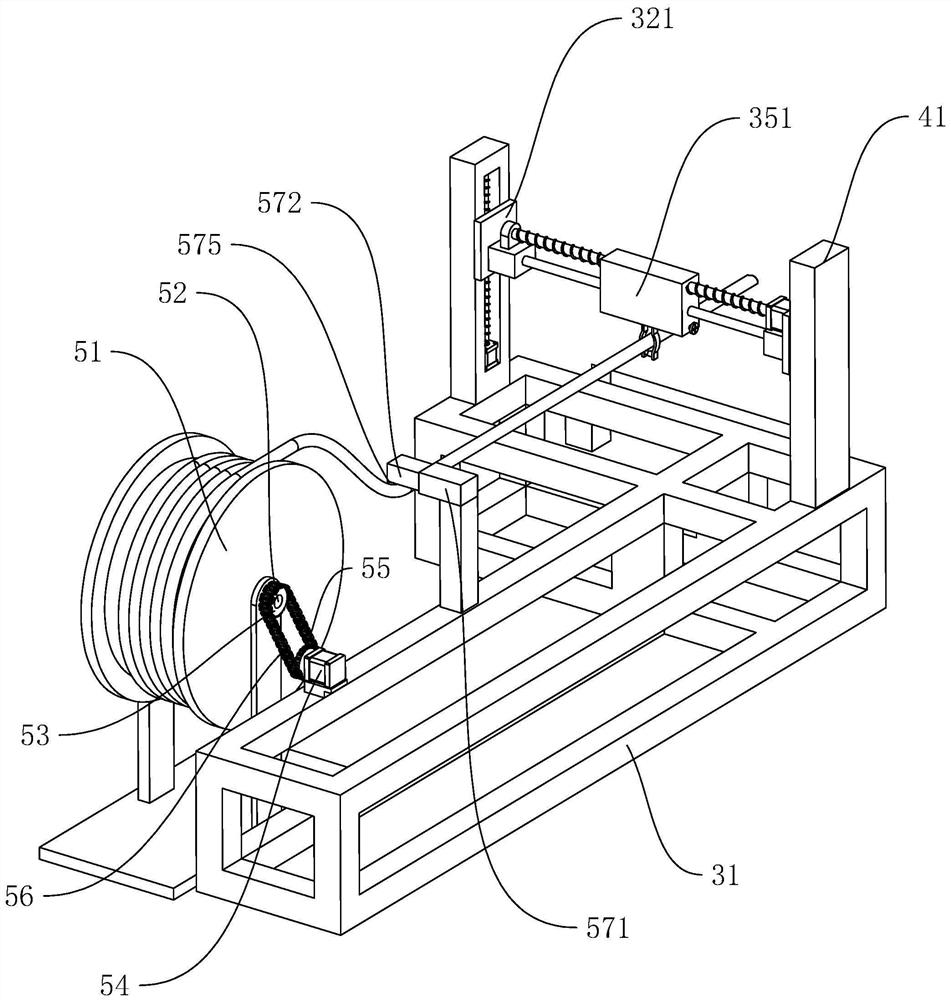

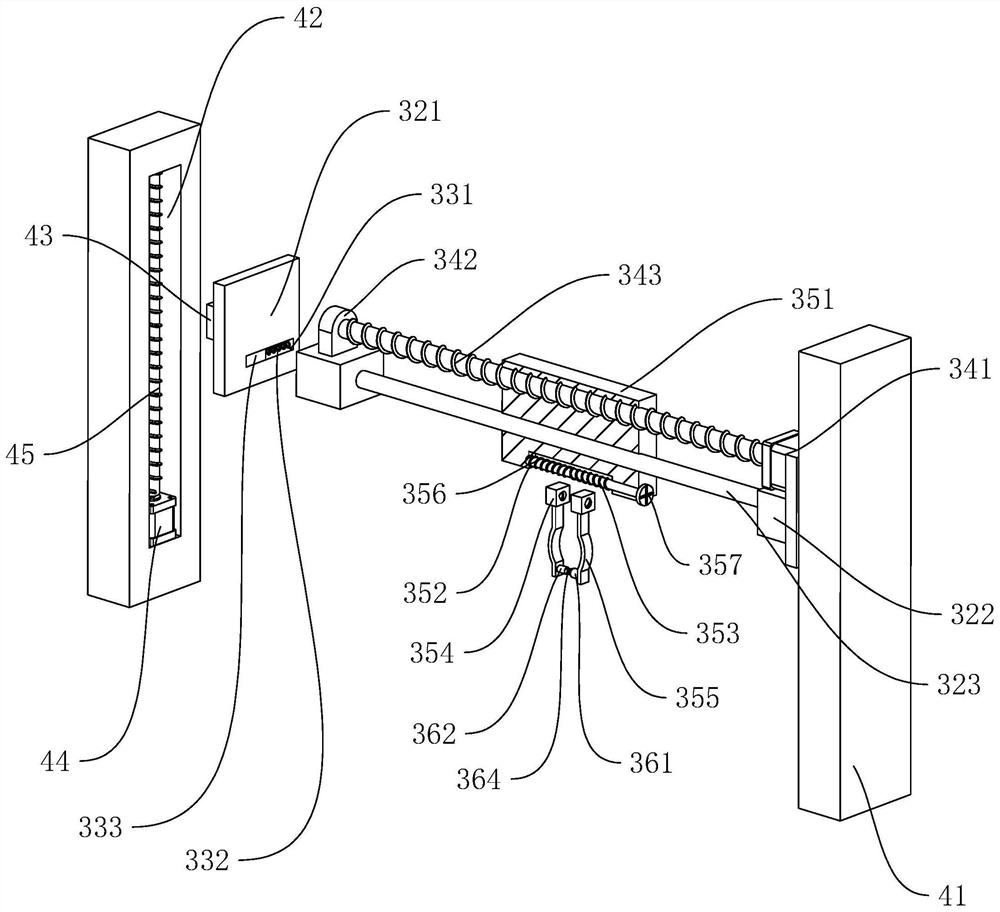

[0036] refer to figure 1 , figure 2 , an extrusion production line for pipeline production, including an extruder body 1, a cooling box 2, and a traction assembly sequentially arranged in a working environment, wherein the input end of the extruder body 1 is connected to the screw feeder The output ends are connected, the screw feeder inputs the color masterbatch, melts and extrudes the color masterbatch through the extruder body 1, and forms a preliminary pipeline shape, the input end of the cooling box 2 and the output of the extruder body 1 The ends are connected so that the initially formed pipeline is cooled by the cooling box 2 to form a formed pipeline. The output end of the cooling box 2 is connected to the input of the traction assembly. The formed pipeline ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap