A kind of equipment for applying mud to tiles for building construction

A technology of building construction and ceramic tiles, which is applied in the direction of construction and building construction, can solve the problems of only intermittent pasting and cumbersome cement operations, and achieve the effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0021] first embodiment

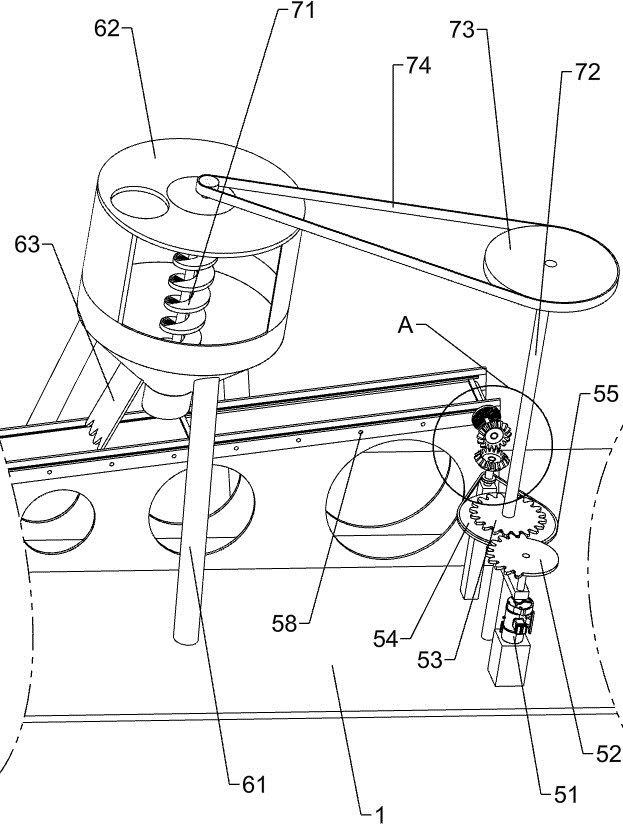

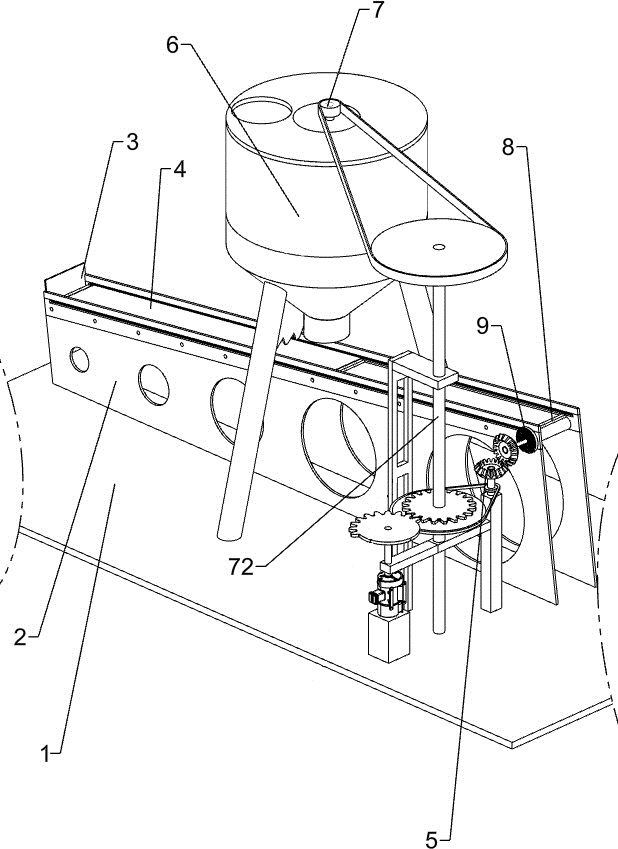

[0022] A kind of equipment for applying mud to ceramic tiles for building construction, such as figure 1 with figure 2 As shown, it includes a working plate 1, a side plate 2, a baffle plate 3, a stopper 8, a drive assembly 5 and a charging assembly 6. A baffle plate 3 is slidably connected to the top rear end, a driving assembly 5 is connected between the side plate 2 and the working plate 1, a stopper 8 is installed on the driving assembly 5, and a charging assembly 6 is installed in the middle of the working plate 1.

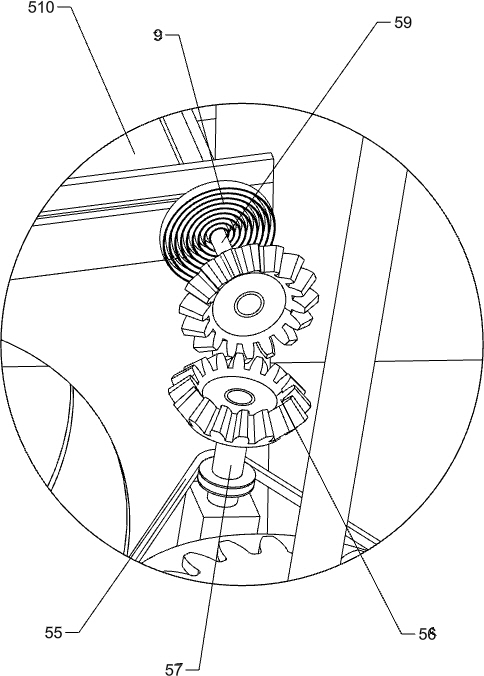

[0023] The driving assembly 5 includes a motor, a half gear 52, a circular gear 53, a first pulley 54, a first conveyor belt 55, a bevel gear 56, a first rotating shaft 57, a cylinder 58, a second rotating shaft 59 and a large belt 510, and the top of the working plate 1 The left front side is equipped wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com