Full-automatic corrugated paper flattening machine

A corrugated paper and flattening machine technology, applied in the direction of mechanical processing/deformation, metal processing, etc., can solve the problems of inability to adjust the height of the flattening, unable to achieve automatic flattening, trouble, etc., to achieve the effect of easy collection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

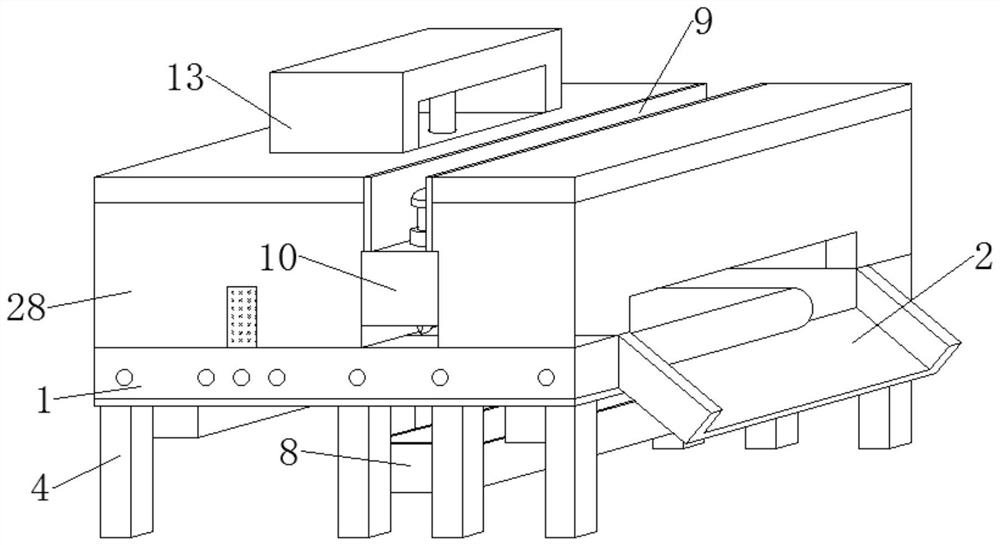

Embodiment 1

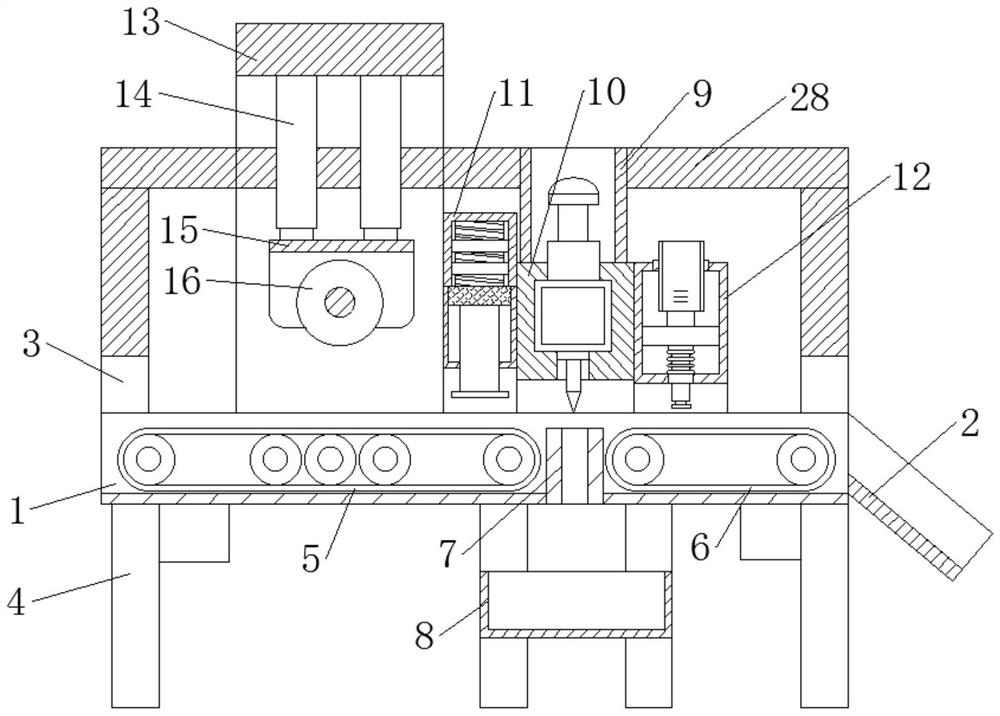

[0030] see Figure 1-6 , a fully automatic corrugated paper flattening machine, comprising a track 1, a plurality of support legs 4 are fixedly connected to the lower end of the track 1, a conveyor belt 5 is installed on one side of the track 1, and a conveyor belt 2 6 is installed on the other side of the track 1, and the track One end of 1 is fixedly installed with a discharge chute 2, and the outer side of the upper end of the track 1 is fixedly connected with a protective shell 28, and the end of the protective shell 28 far away from the discharge chute 2 is provided with a feed port 3, and the upper end of the protective shell 28 is equipped with a support seat 13, Two hydraulic rods 14 are fixedly connected at the top of the support seat 13, and the lower end of the hydraulic rod 14 is fixedly connected with a fixed seat 15, and the fixed seat 15 is rotatably connected with a pressure roller 16, and three driven rollers are installed in the conveyor belt one 5.

[0031] ...

Embodiment 2

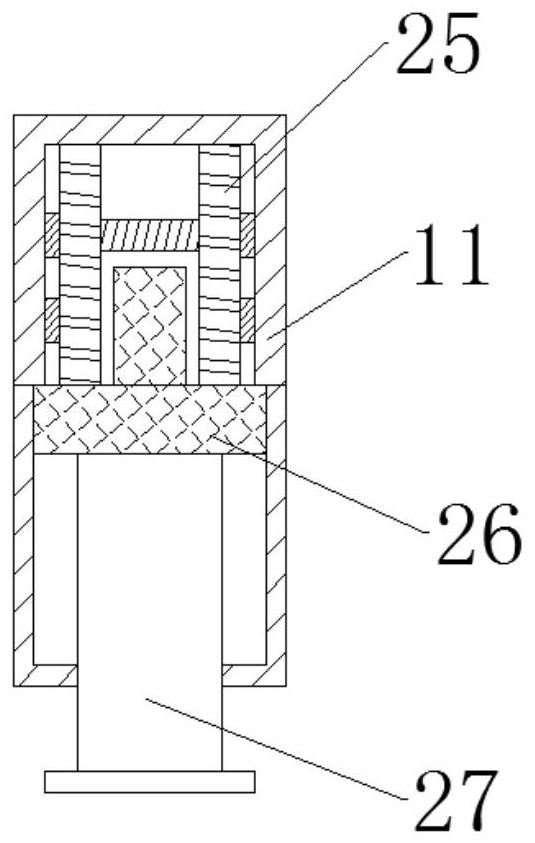

[0034] Based on Example 1, such as Figure 1-6 , the upper end of the protective case 28 away from the end of the support seat 13 is provided with a push rod groove 9, the lower end of the push rod groove 9 is fixedly connected with the cutting device 10, the two side walls of the cutting device 10 are fixedly connected with the inner side wall of the protective case 28; one end of the cutting device 10 is fixed A pressing device 11 is connected, and the other end of the cutting device 10 is fixedly connected with a fixing device 12; the cutting device 10 is movably connected with a sliding seat 21, and the upper end of the sliding seat 21 is fixedly connected with a middle part fixedly connected with a limit seat, and the inside of the limit seat is movably connected Push rod 22 is arranged, and the upper end of push rod 22 is arranged on the inside of push rod groove 9, and telescopic rod 23 is movably connected in slide seat 21, and telescopic rod 23 is fixedly connected wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com