A device and method for screening needle-shaped crushed pebbles

A screening device and needle-like technology, which is applied in chemical instruments and methods, sieves, solid separation, etc., can solve the problems of subjective misjudgments by testers, long test periods, inaccurate test results, etc., and eliminate human visual inspection. Error, shorten the test cycle, reduce the effect of test time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

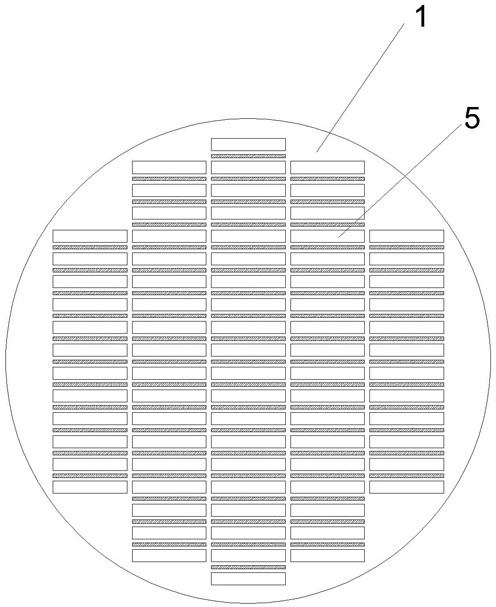

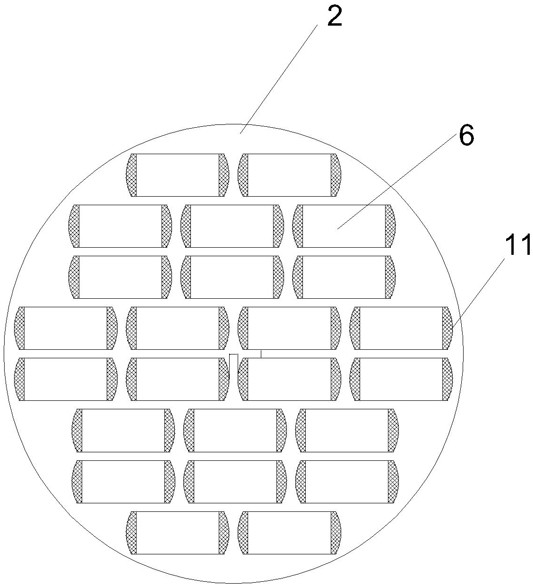

[0027] A needle-shaped crushed pebble screening device provided in this embodiment includes a sheet-shaped screen 1, a needle-shaped screen 2, a screen wall 3, and a screen support 4. The screen wall 3 and the screen support 4 are fixedly connected. The screen 1 and the needle screen 2 are replaceably placed on the screen support 4. The inner diameter of the upper opening of the screen wall 3 is slightly larger than the diameter of the sheet screen 1 and the needle screen 2. The lower part of the screen support 4 The inner diameter of the upper opening of the screen wall 3 is the same, which is convenient to be combined with the screen bottom tray 9. The sheet screen 1 is provided with screen through holes 5, and the needle screen 2 is provided with screen needle through holes 6.

[0028] The number of through-holes 5 of the sieve screen 1 is made according to the nominal size of the stone according to Table 7.9.3-2 in (JGJ 52-2006). The width of the lower part of 5 refers to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com