Gas mass flow controller and flow calibration method thereof

A technology of gas mass flow and flow control device, which is applied in the direction of mass flow measurement device, test/calibration volume flow, liquid/fluid solid measurement, etc., can solve the problems of poor real-time and accuracy of calibration, affecting economic benefits, wasting time, etc. , to achieve the effect of convenient real-time online calibration, good real-time performance and accuracy, and avoid excessive pressure fluctuations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0054] In order for those skilled in the art to better understand the technical solutions of the present invention, the gas mass flow controller and the flow calibration method thereof provided by the present invention are described in detail below with reference to the accompanying drawings.

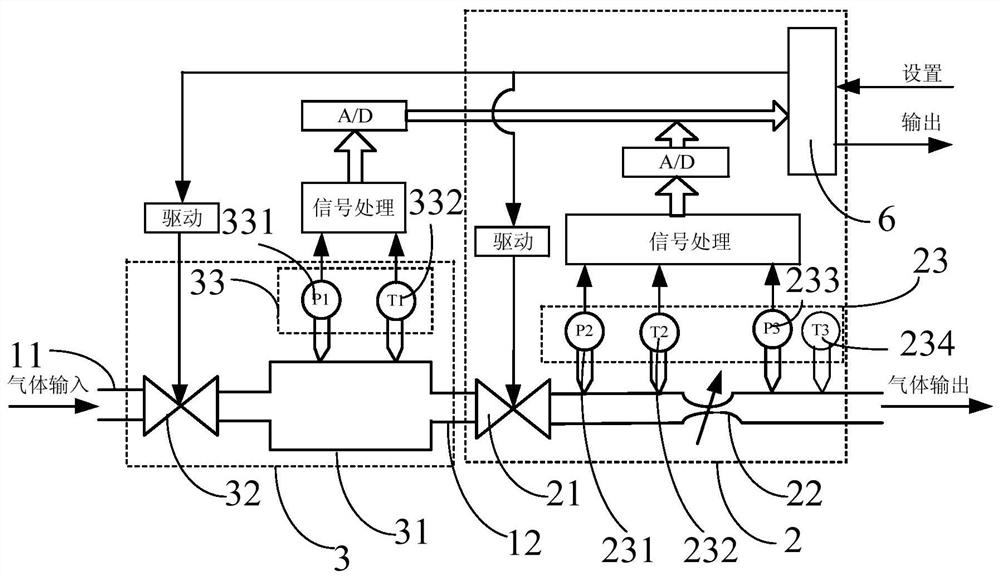

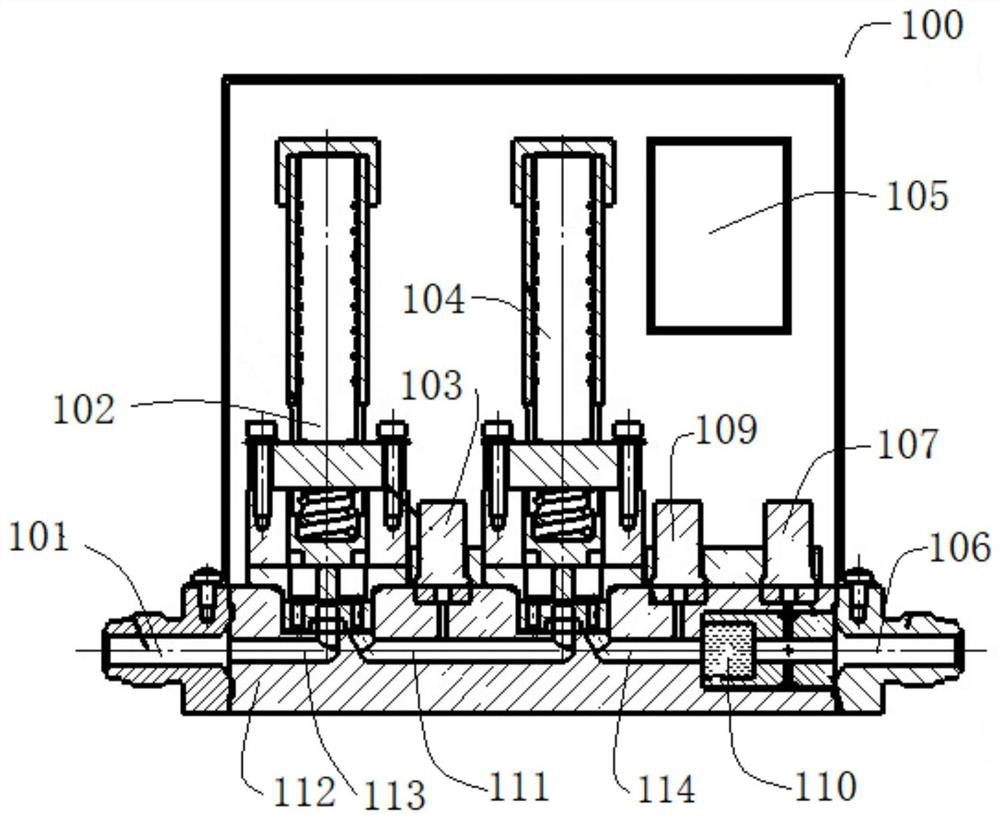

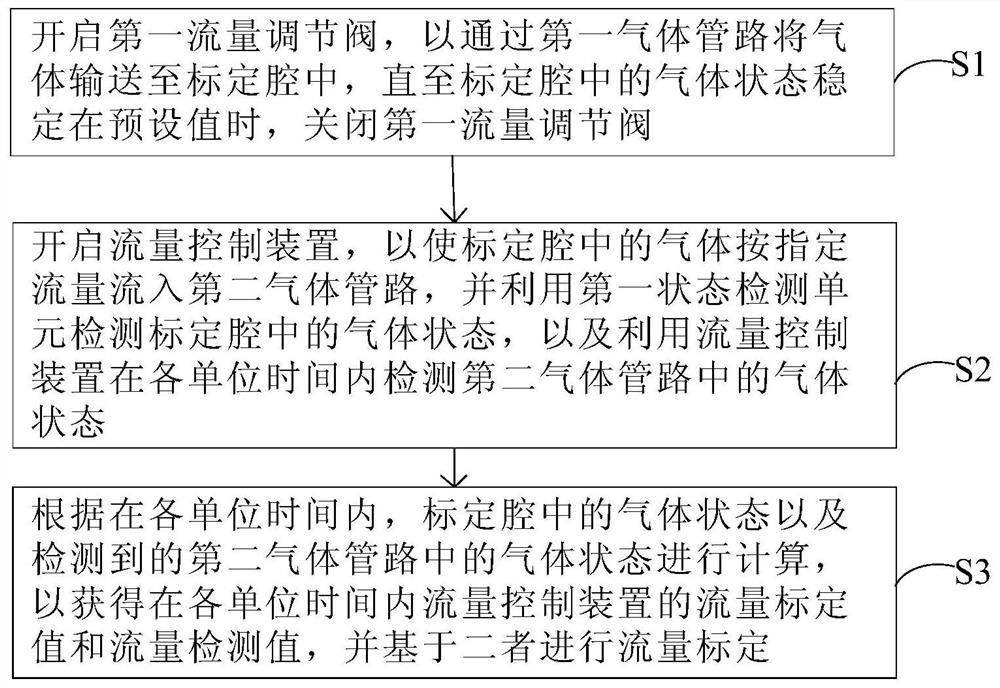

[0055] see figure 1 , the gas mass flow controller (Mass Flow Controller, MFC for short) provided by the first embodiment of the present invention, the gas mass flow controller is used for precise measurement and control of the gas mass flow in the pipeline to be measured (not shown), and It includes a first gas pipeline 11, a second gas pipeline 12, a flow control device 2, a flow calibration device 3 and a control unit 6, wherein the first gas pipeline 11 and the second gas pipeline 12 are sequentially connected to the on the test line. The flow calibration device 3 includes a calibration cavity 31, a first flow regulating valve 32 and a first state detection unit 33, wherein the inp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com