A tensile testing machine and its traction mechanism

A technology of tensile testing machine and traction mechanism, which is applied in the direction of applying stable tension/pressure to test the strength of materials, instruments, measuring devices, etc. It can solve the problems of being unable to adapt to the tensile testing of various products and the stroke limit of hydraulic presses, etc., to achieve Realize the effect of large-scale tensile test, less deflection force and increased stroke

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The technical solutions in the present invention will be further described below with reference to the accompanying drawings and embodiments.

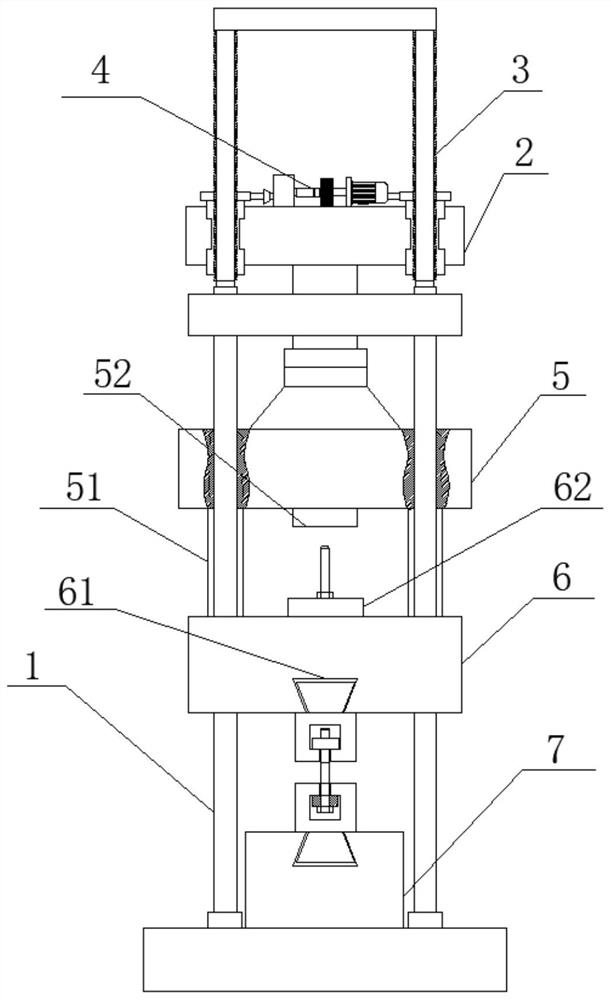

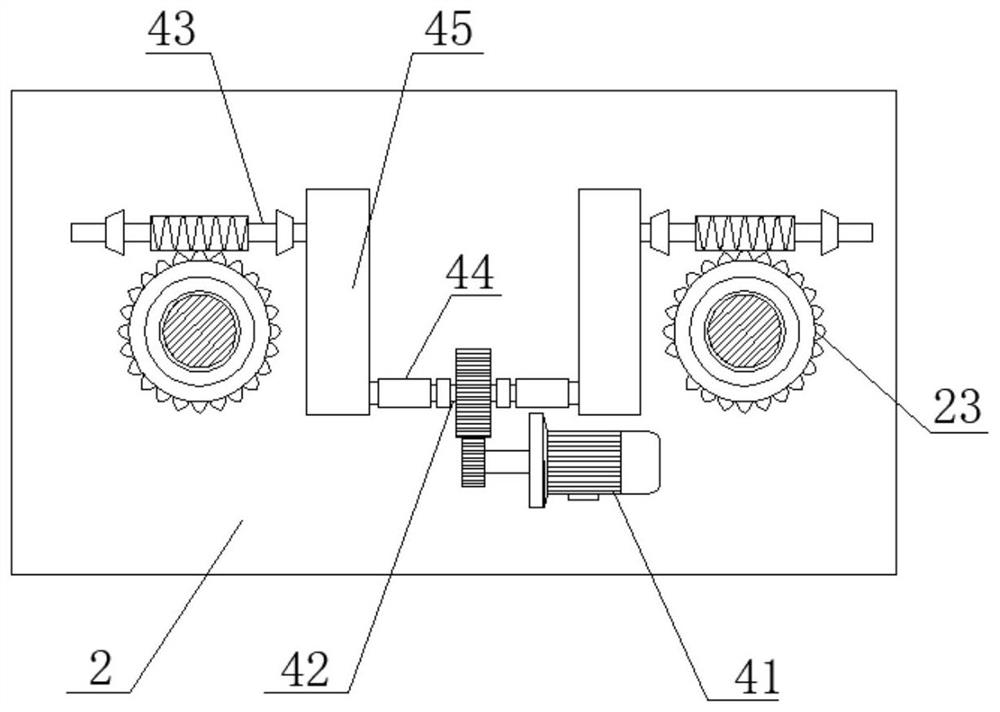

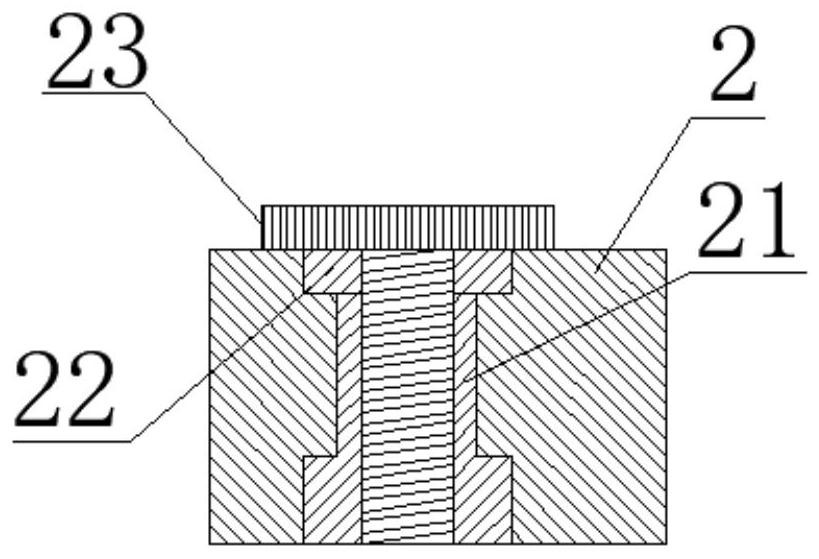

[0019] like Figure 1-3 As shown, the embodiment of the present invention proposes a traction mechanism, which includes a machine base 2, a transmission screw 3 and a drive unit 4; the transmission screw 3 has two parallel to each other, and the two transmission screws 3 and the machine base 2 are provided with a transmission cylinder 21, the transmission cylinder 21 is rotatably connected to the base 2, the transmission screw 3 passes through the transmission cylinder 21 and is threadedly connected with the transmission cylinder 21; the drive unit 4 is fixed On the base 2 , a transmission gear 23 is fixed on the transmission cylinder 21 , and the drive unit 4 includes two worms 43 that drive the two transmission gears 23 simultaneously. The load is connected to the base 2, and the present invention adopts two transmission scre...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com