Resistance adjusting method for automobile data recorder support of new energy automobile

A technology of driving recorder and new energy vehicles, which is applied to vehicle parts, transportation and packaging, etc., and can solve the problem of not being able to adjust the viewing angle of the owner

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

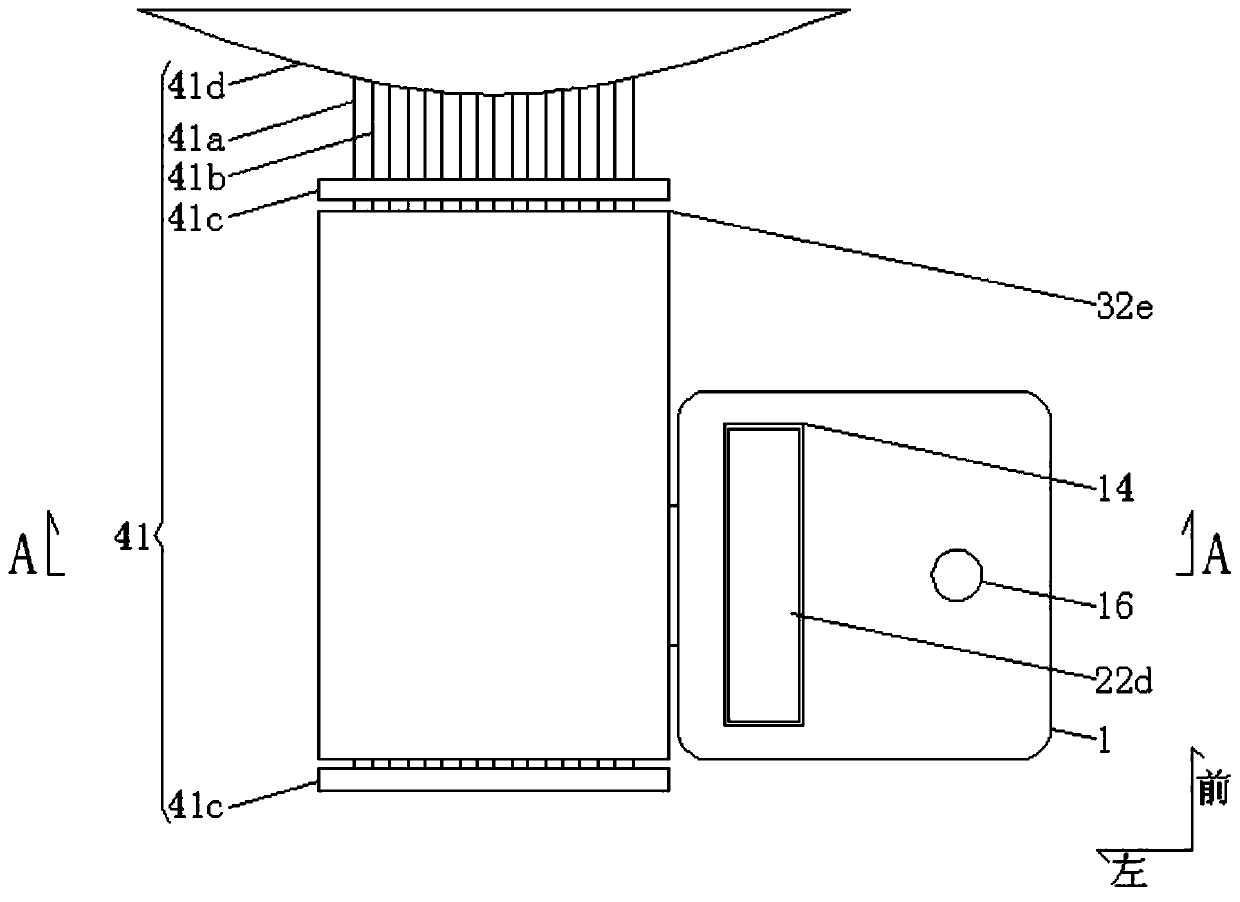

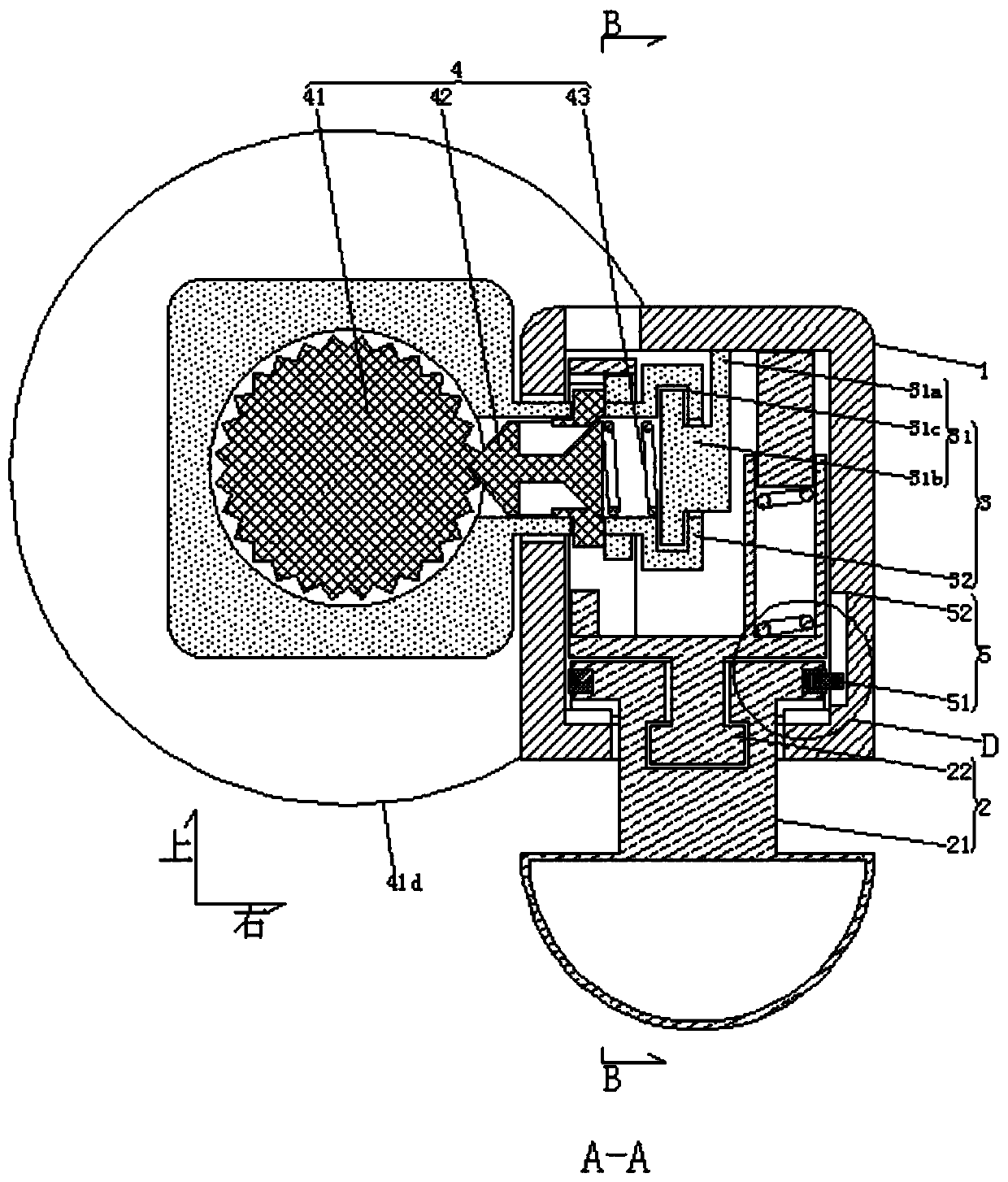

[0070] The installation foundation 1 includes a rectangular sleeve 11 in the shape of a hollow rectangular body, a lower vertical shaft hole 12 arranged at the center of the bottom of the rectangular sleeve 11, and a second hole 12 arranged on the upper end of the bottom of the rectangular sleeve 11 and evenly distributed around the lower hole 12 of the vertical shaft. A main locking tooth 13, an upper opening 14 is provided on the left side of the upper end of the rectangular sleeve 11, and a left opening 15 is provided on the upper left end of the rectangular sleeve 11;

[0071] The vertical shaft assembly 2 includes:

[0072] The lower vertical shaft assembly 21 includes a cylindrical shaft 21a slidably inserted in the lower hole 12 of the vertical shaft, a vertical shaft lock disk 21b formed on the upper end of the cylindrical shaft 21a, and a circumferentially uniformly distributed under the vertical shaft lock disk 21b The first auxiliary locking tooth 21c with the end surfac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com