Intelligent ship for measuring large ship water gauge and measuring method

A smart ship and water gauge technology, applied in the field of smart ships, can solve the problems of effect discount, poor timeliness, and high cost, and achieve the effects of accurate benefits, guaranteed accuracy, and convenient benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

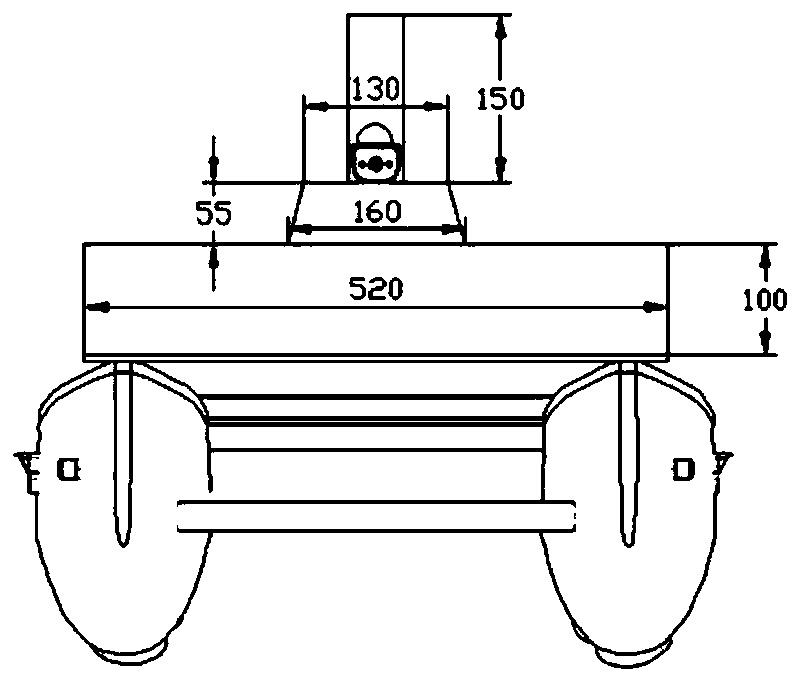

[0039] Now take the conical hull with a length of 220cm and a height of 60cm as an example (energy supply: 150W watt monocrystalline solar photovoltaic panel + full power direct charge 12v volt battery), under airtight conditions, all equipment can work normally.

[0040] Step 1: Make the hull and upper wooden box structure (such as image 3 ,4,5 as shown in the three views of the smart ship)

[0041] (1) Use computer three-dimensional modeling to make a schematic diagram of the overall structure of the smart ship, such as image 3 smart boat front view, Figure 4 Smart boat left view, Figure 5 The top view of the smart ship, and then according to the schematic diagram, use the corresponding wooden materials to make the hull components according to the digital model, and complete the assembly of the smart ship's solid wooden structure;

[0042] (2) Polish the catamaran and seal it with sealant to ensure that the hull does not leak;

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com