A system for monitoring and remediating discharge of industrial pollution sources and its operation method

A technology of operation method and pollution source, applied in control/manipulation systems, chemical instruments and methods, water/sewage treatment, etc., which can solve the problem of long time interval between pollution and treatment, insane growth of biological harmful algae in water bodies, limited supervisors, and supervision. Problems such as the decrease in inspection strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment example 1

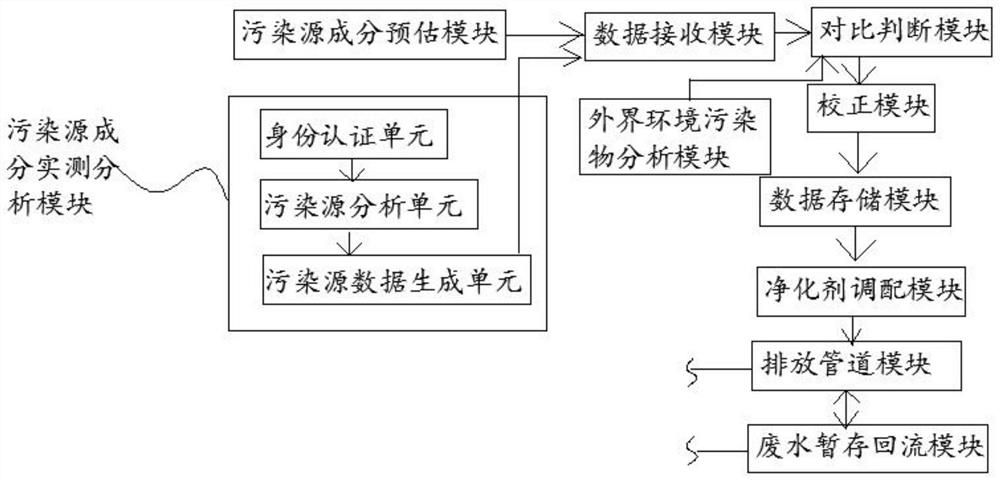

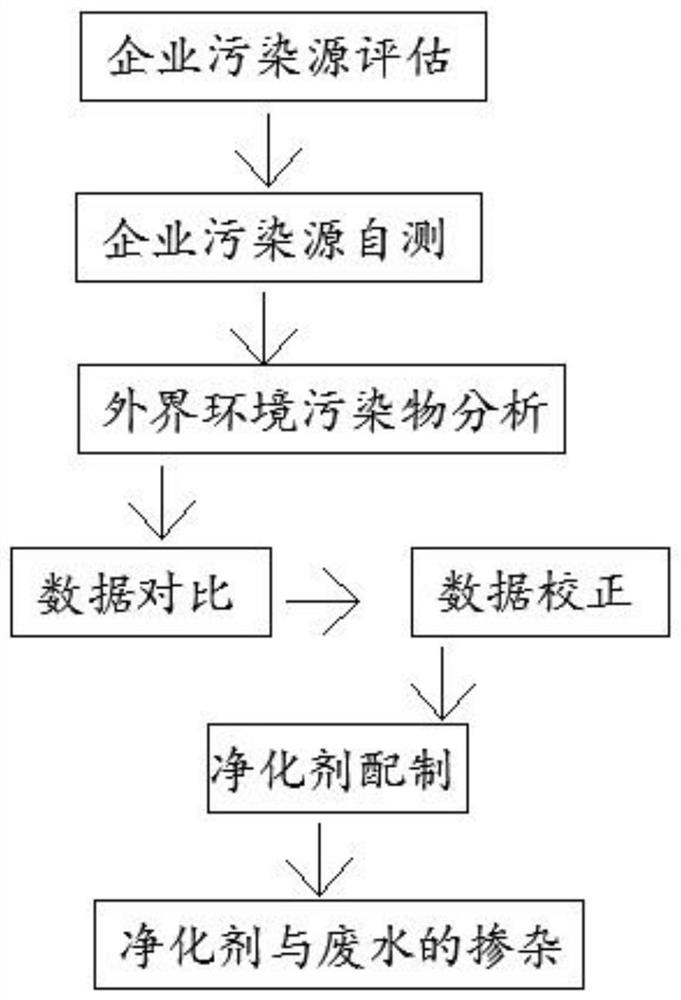

[0030] A system for monitoring and rectifying the discharge of industrial pollution sources, comprising: a pollution source reporting subsystem used by pollution source enterprises, an external pollution source monitoring subsystem used by regulatory authorities; and a wastewater purification subsystem used by sewage rectification enterprises;

[0031] The pollution source reporting subsystem includes a pollution source component estimation module and a pollution source component actual measurement and analysis module; the pollution source component estimation module is used by the enterprise to formulate data on harmful components in the pollution source according to the main business scope of the enterprise; the pollution source component measured and analyzed The module includes an identity authentication unit, a pollution source analysis unit, and a pollution source data generation unit connected in sequence, the identity authentication unit is used to identify the ID inform...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com