A fully automatic movable coal level gauge

A fully automatic, coal level technology, applied in the direction of engine components, machine/engine, engine lubrication, etc., can solve the problems of insufficient coal measurement data, affecting the accuracy of coal inventory, and low work efficiency, so as to improve the measurement Comprehensiveness, improve work efficiency and safety, and enhance the effect of scope of application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

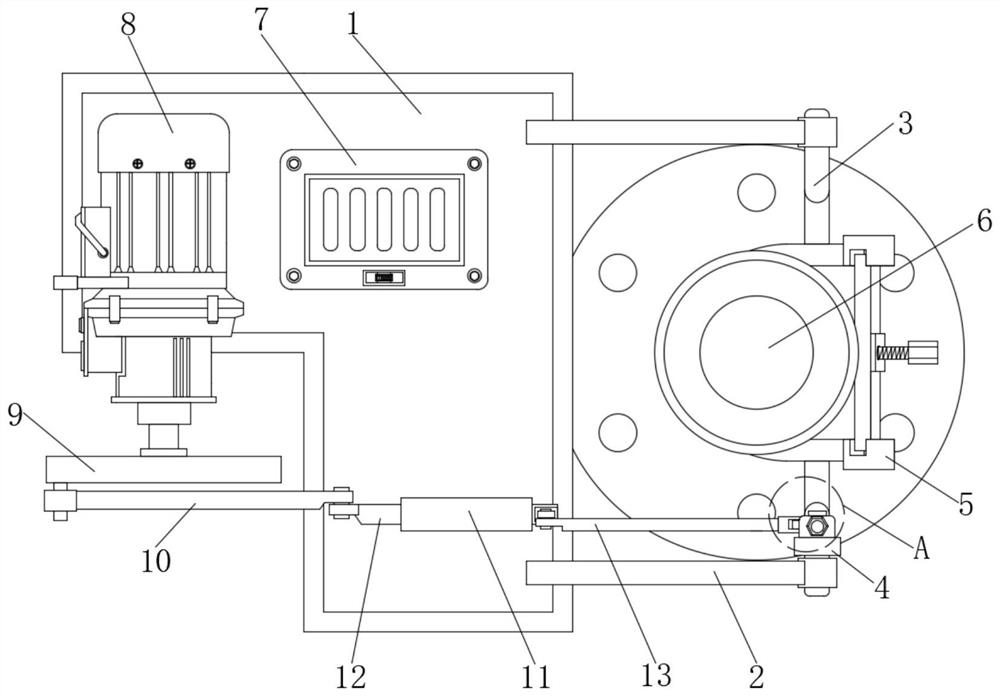

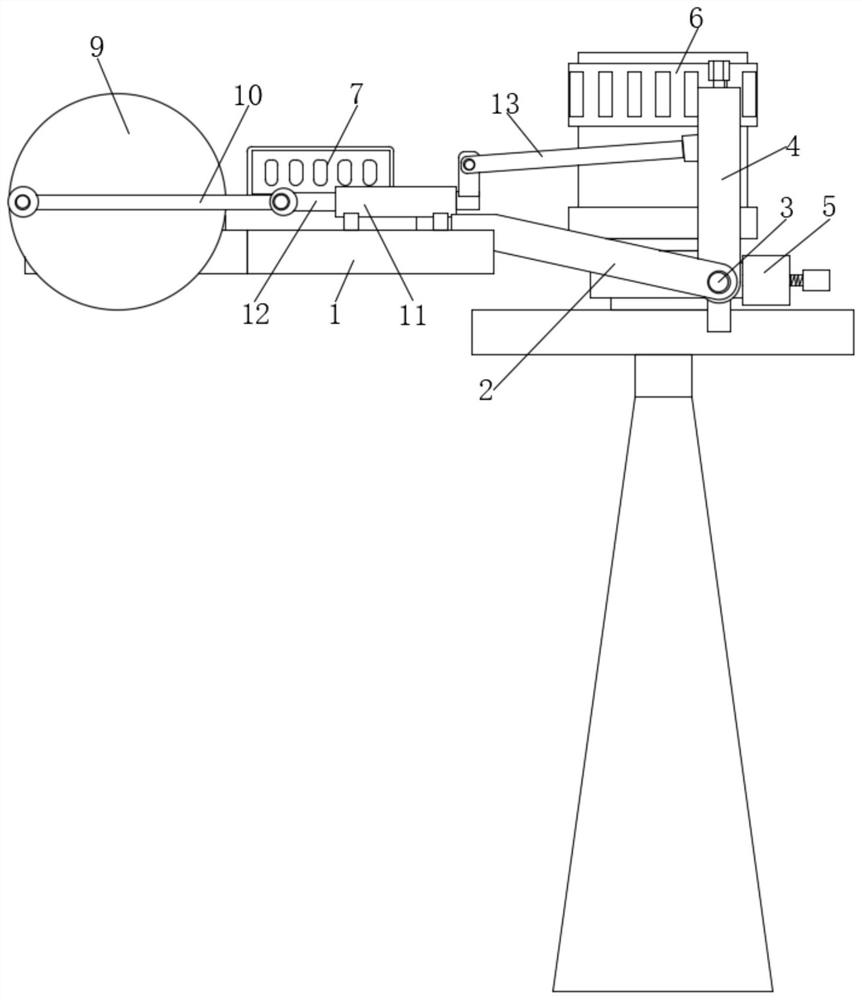

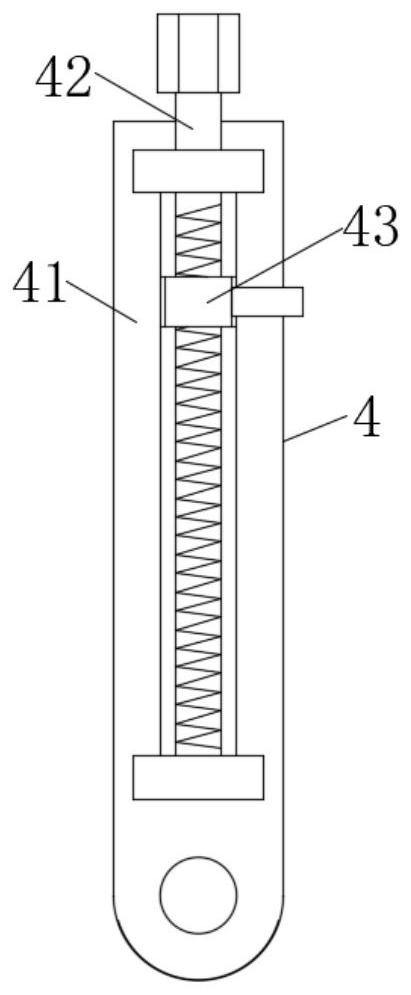

[0046] see Figure 1-6 , a fully automatic movable coal level gauge, including a base 1, a control panel 7 and a motor 8, the right side of the base 1 is connected and fixed with a support frame 2, and the other end of the support frame 2 is inserted with a rotating shaft 3, the rotating shaft 3 The outer side of the support plate 41 is connected and fixed with an adjustment frame 4, the adjustment frame 4 includes a support plate 41, a first screw rod 42 and an adjustment sleeve 43, the bottom of the support plate 41 is fixedly connected to the outside of the rotating shaft 3, and the back of the support plate 41 is inserted through a support. A screw rod 42, the outer cover of the first screw rod 42 is provided with an adjusting sleeve 43, the first screw rod 42 is rotationally connected with the support plate 41, the thread assembled on the outside of the first screw rod 42 is compatible with the thread assembled on the inner wall of the adjusting sleeve 43, adjusts The sle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com