Electronic wire connecting device with anti-falling function

A technology for connecting devices and electronic wires, which is applied to the components, connections, coupling devices and other directions of connecting devices, can solve problems such as inconvenient operation, and achieve the effects of convenient operation and improved fixing effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0026] Example one

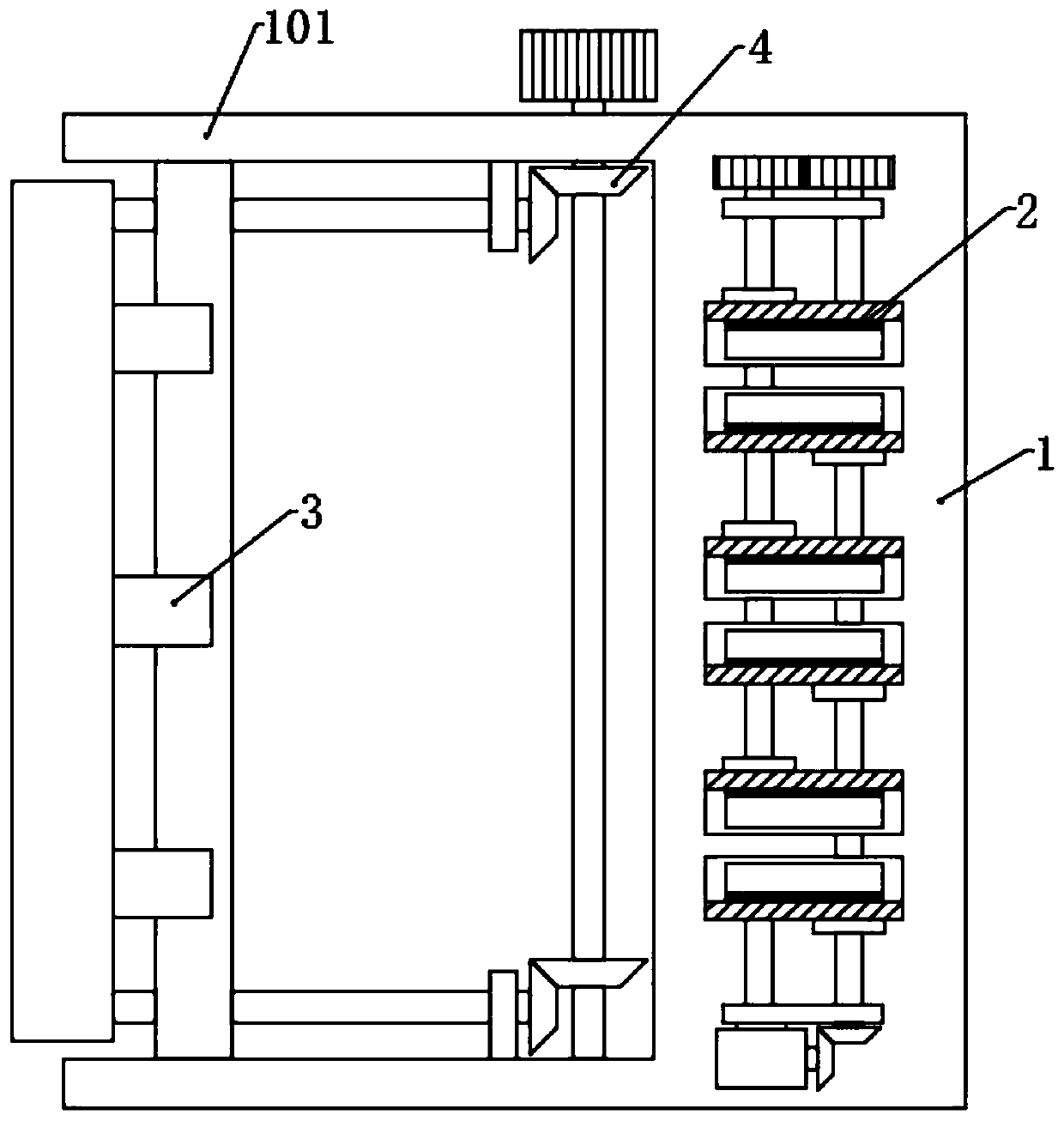

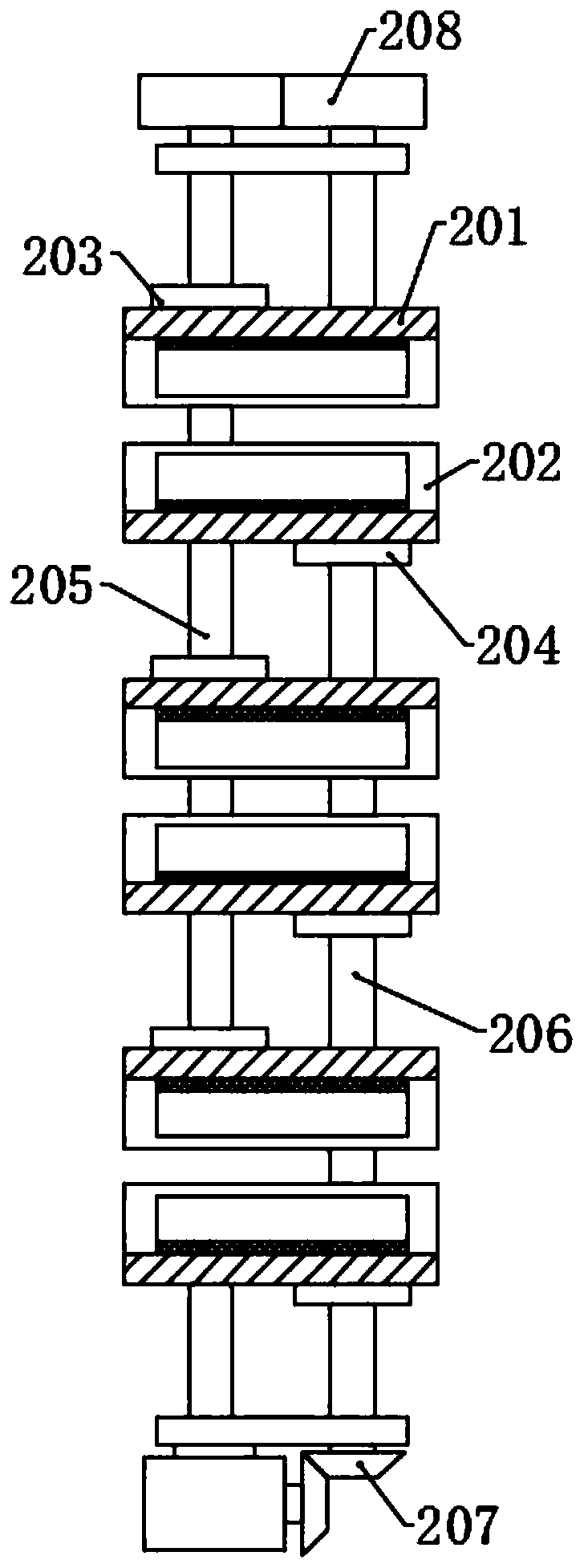

[0027] Please refer to the drawings, the present invention provides a technical solution: an electronic wire connection device with anti-dropping function, comprising a fixing table 1, a fixing assembly 2 is arranged on the top surface of the fixing table 1, and the left side of the fixing table 1 is symmetrically fixed There are two side plates 101, and a limiting component 3 is arranged between the two side plates 101; the fixing component 2 includes a plurality of first splints 201 and second splints 202 evenly and spaced apart, and the first splint 201 and the second splint The splints 202 are all circular arc plates, the first slider 203 is fixed on the left side of the bottom of the plurality of first splints 201, the first screw rod 205 is sleeved in the first slider 203, and the bottom of the plurality of second splints 202 A second sliding block 204 is fixed on the right side, and a second screw rod 206 is sleeved on the multiple second sliding block...

Example Embodiment

[0034] Example two

[0035] The structure of this embodiment is basically the same as that of the first embodiment. The difference is that an adjustment assembly 4 is provided under the limit assembly 3, and the adjustment assembly 4 is connected to the side plate 101 correspondingly. The adjustment assembly 4 includes sliding connection on both sides The adjustment plate 401 between the plates 101, the top surface of the adjustment plate 401 is uniformly fixed with a plurality of inclined connecting rods 402, the top of the connecting rod 402 is fixedly connected with the lower splint 301, the two sides of the adjusting plate 401 are screwed with screws 403, The screw 403 is rotatably connected with the side plate 101, and the right end is fixed with a third bevel gear 404, a rotating shaft 405 is rotatably connected between the right ends of the two side plates 101, and one end of the rotating shaft 405 is fixed with a rotating handle, and A plurality of fourth bevel gears are ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com