Whale optimization algorithm-based multi-target semi-automatic assembly line design method

An optimization algorithm and design method technology, applied in computer-aided design, design optimization/simulation, calculation, etc., can solve problems such as only considering time or production efficiency, so as to reduce operating costs and energy consumption, low energy consumption, and improve production efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

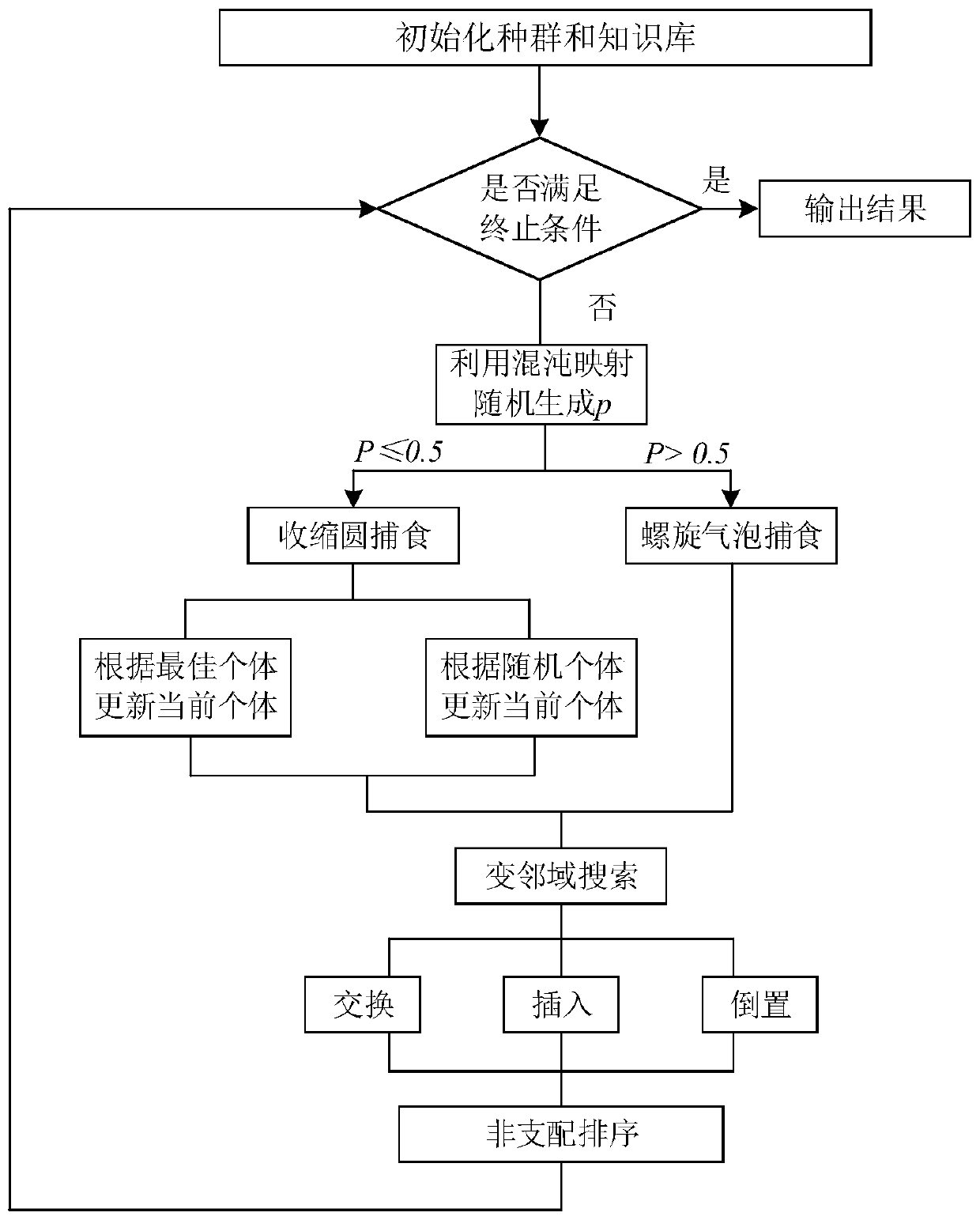

[0064] This application proposes a multi-objective semi-automatic assembly line design method based on the whale optimization algorithm, including the following steps:

[0065] Step S1: Obtain the basic parameters of the semi-automatic assembly line, including workstations, process conditions, energy consumption parameters, fixed costs of the assembly line, etc.;

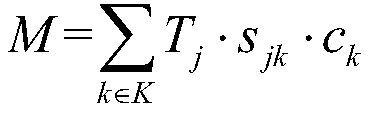

[0066] Step S2: According to the obtained basic parameters, on the premise of fully understanding the energy consumption mechanism of the semi-automatic assembly line, aiming at optimizing the tempo, energy consumption and cost of the semi-automatic assembly line at the same time, establish a multi-objective optimization model for tempo, energy consumption and cost, Objective functions include:

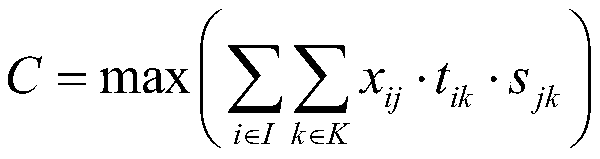

[0067] Beat function:

[0068]

[0069] Among them, I represents all process sets, K represents all station type sets, x ij 1 means process i is assigned to station j, x ij 0 means process i is not assigned to station...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com