Ejector device and method for promoting disengagement of components arranged on holding diaphragm

A diaphragm and top-off technology, applied in the manufacturing of electrical components, machines/engines, semiconductor/solid-state devices, etc., can solve problems such as increased air consumption and reduce friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

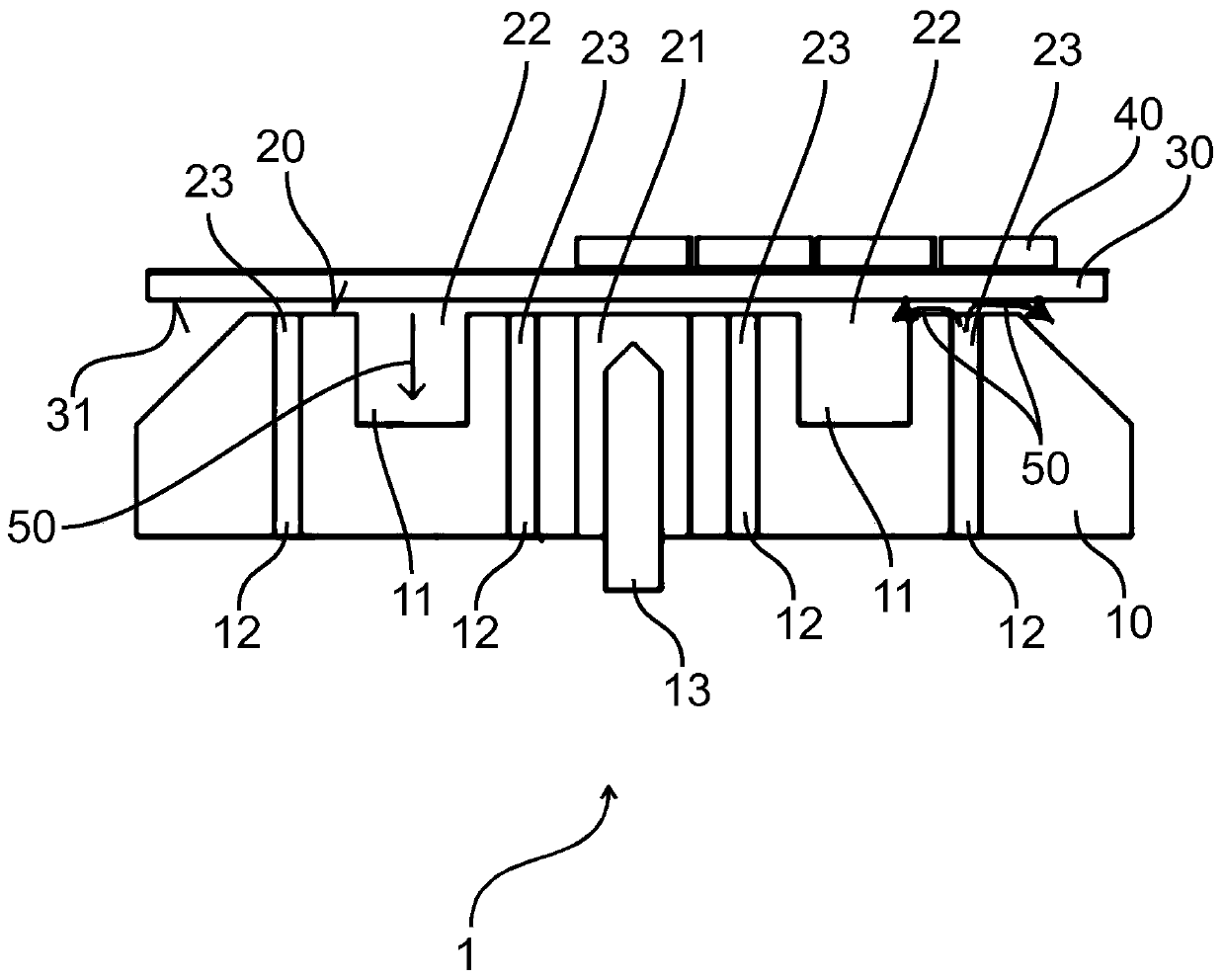

[0044] figure 1 shows the method according to the invention, which can be achieved by, for example figure 2 The illustrated ejector device 1 according to the invention is implemented. exist figure 1 Method steps a) to c) are marked in capital letters. The following will be combined with description figure 1 with figure 2 , where the details of each figure are discussed separately.

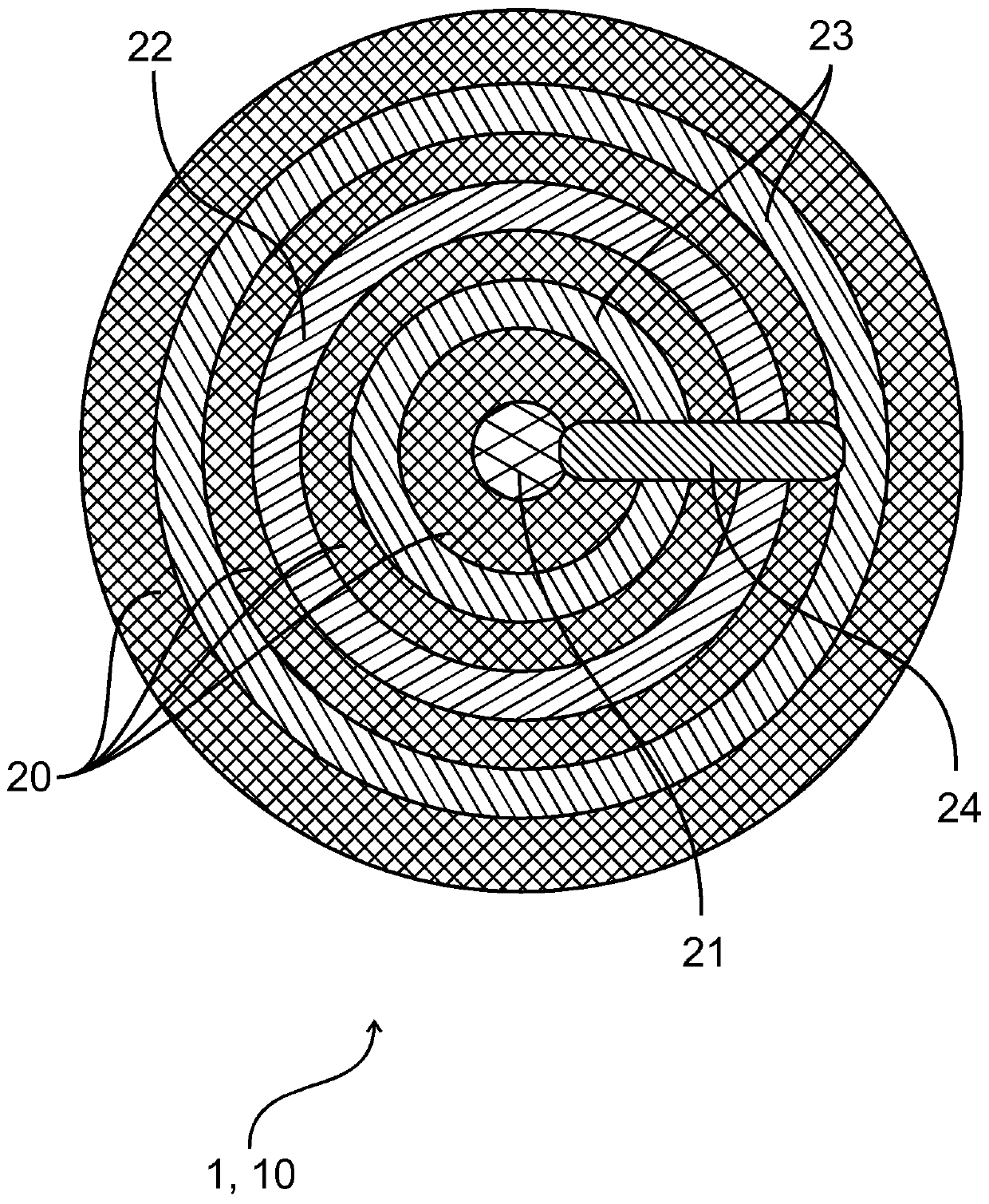

[0045] figure 2 A cross-sectional view of an ejector device 1 according to the invention is shown. In particular, the ejector head 10 is shown. A holding membrane 30 is arranged on the membrane contact surface 20 such that the membrane contact surface 20 of the ejector head 10 faces a surface 31 of the holding membrane 30 facing away from the component. Arranged on the holding membrane 30 facing away from the ejector head 10 is again a part 40 which can be detached from the holding membrane 30 by means of the ejector device 1 according to the invention. For this purpose, the ejector dev...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com