Chiral polymer microsphere with porous structure and preparation method thereof

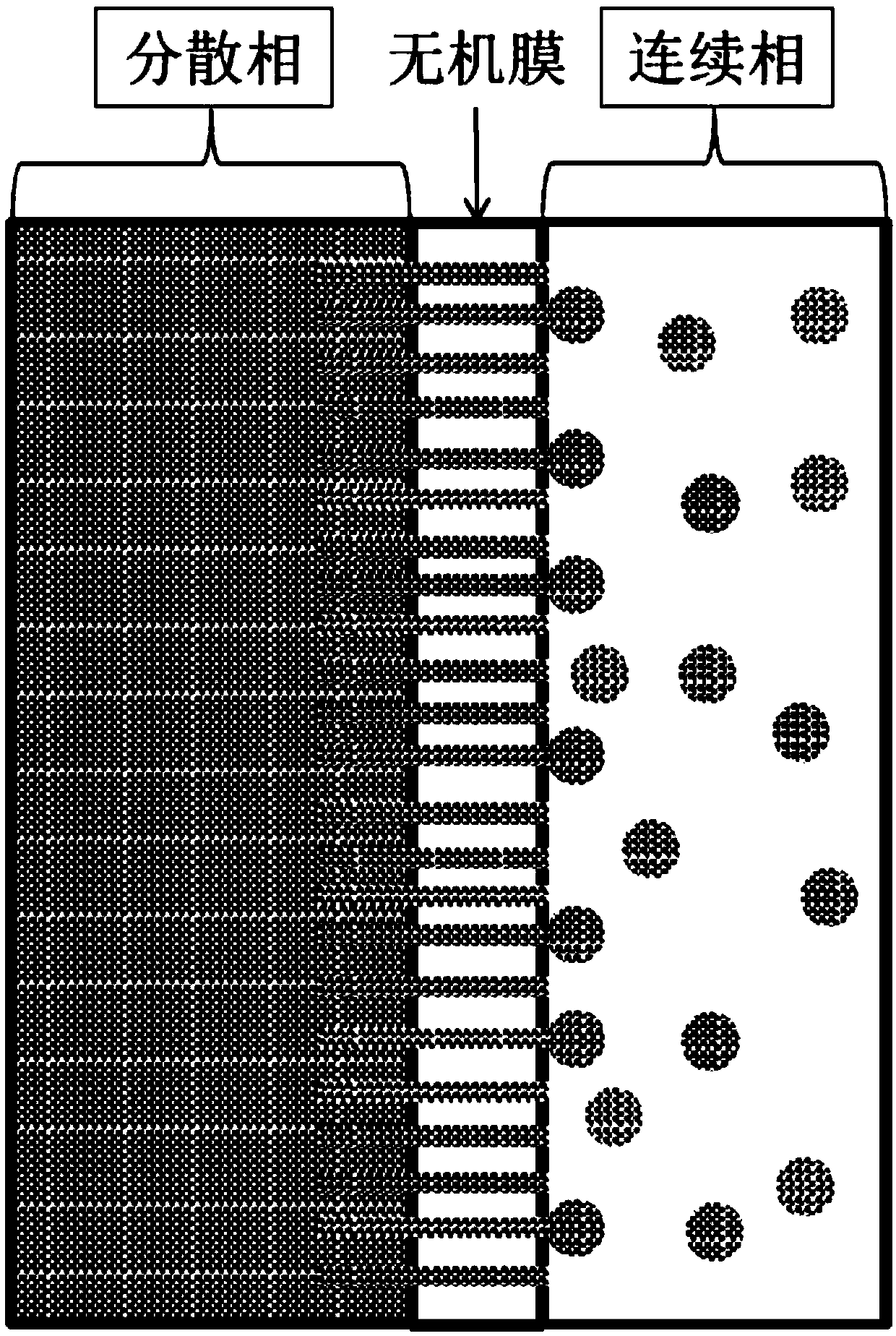

一种多孔结构、聚合物的技术,应用在分离方法、化学仪器和方法、非线性光学等方向,能够解决手性分离承载能力弱、手性点分布不均匀等问题,达到增加手性作用点、提高效果的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

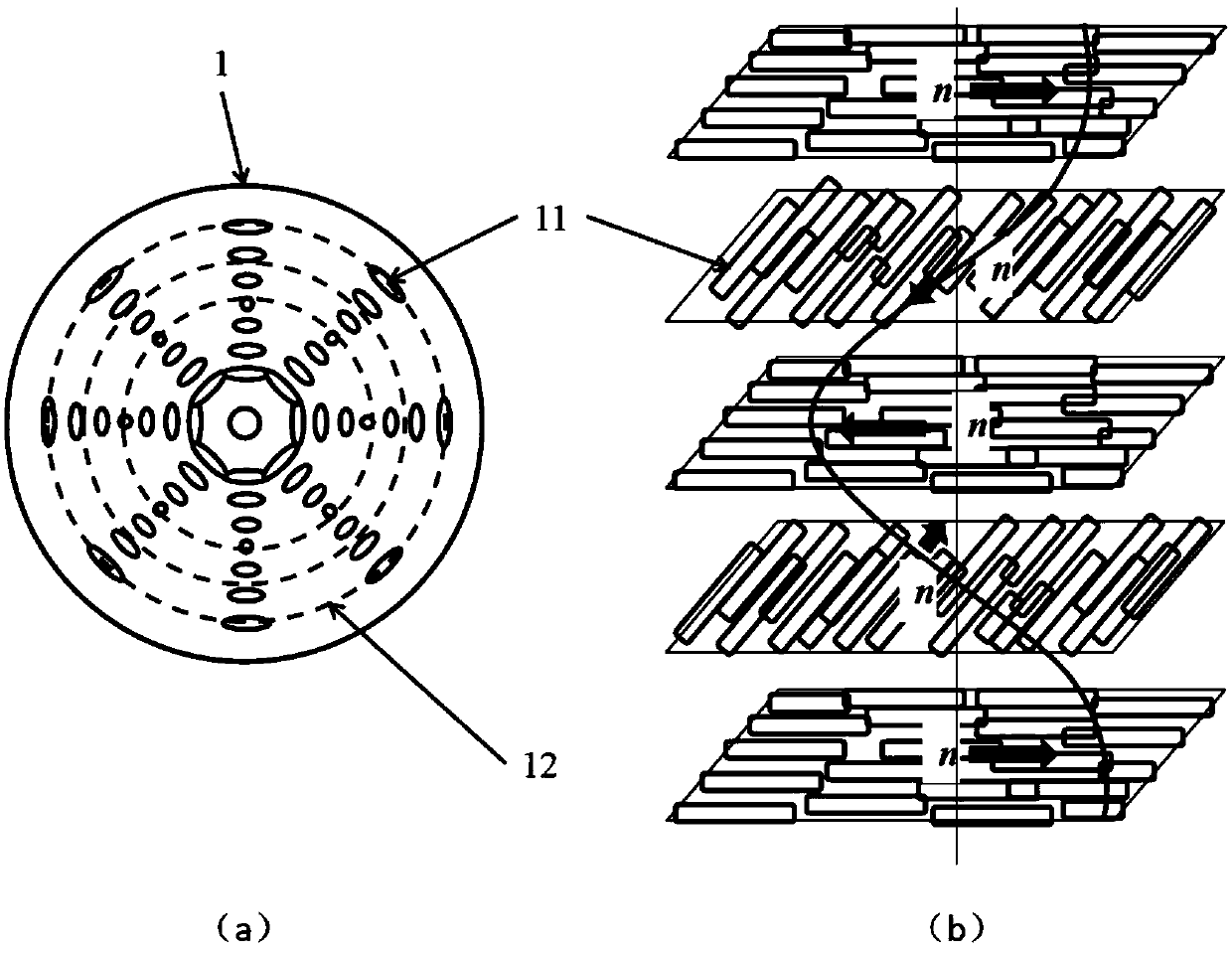

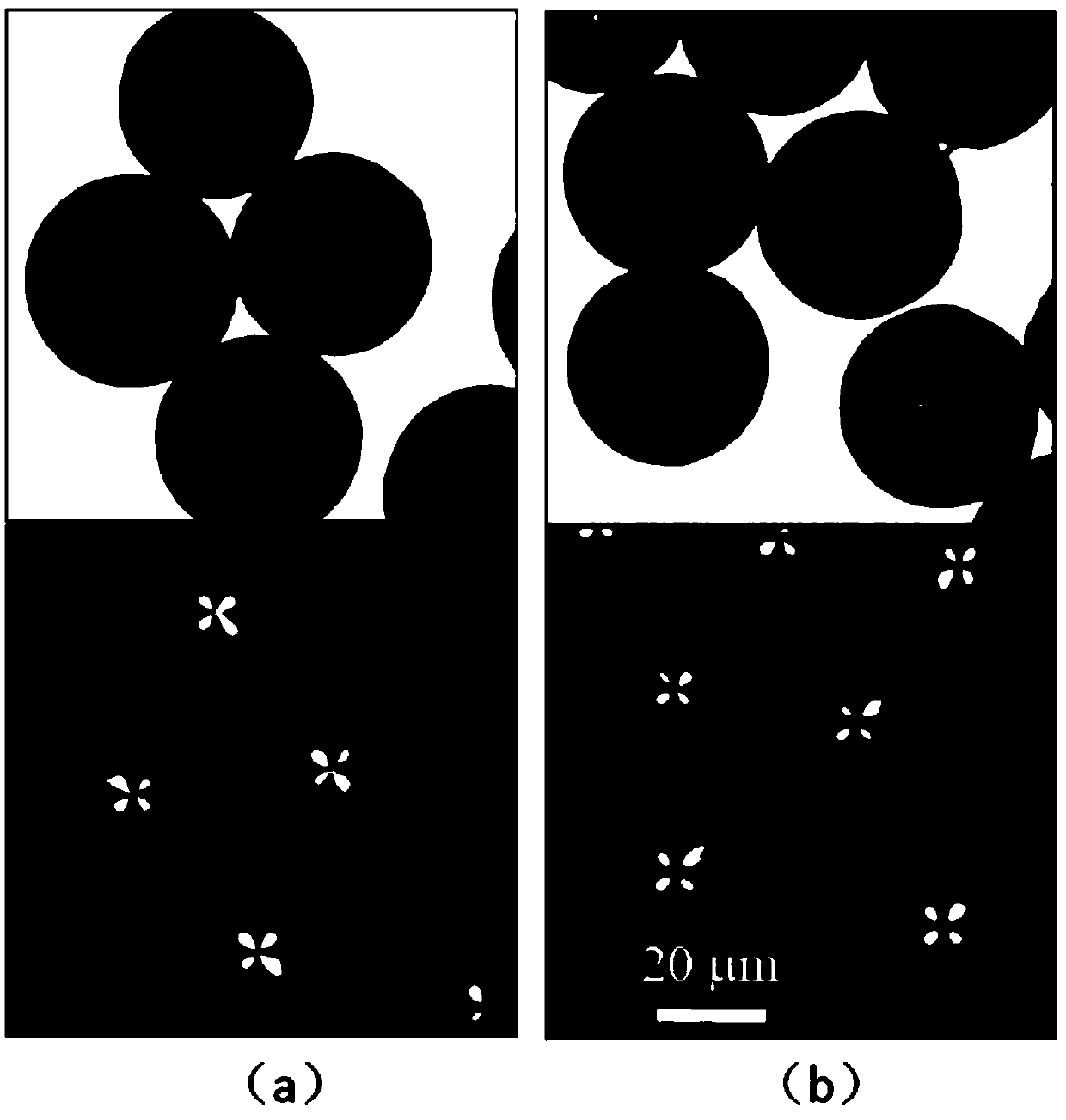

[0053] Prepare the liquid crystal mixture containing 3g reactive liquid crystal RM257, 6.9g non-reactive liquid crystal E7, 0.1g chiral additive and 0.1g photoinitiator DMPAP (reactive liquid crystal accounts for the percentage of liquid crystal mixture is 29.7%), it according to above The steps are to make polymer microspheres, wherein the micropore diameter of the SPG membrane is 10 microns, the continuous phase is water, and the mass percent concentration of surfactant PVA in water is 3.0%. The chiral additives are R5011 and S5011, respectively, wherein R5011 and S5011 have the same molecular structure but opposite optical activities. like image 3 As shown, the average particle size of the two kinds of polymer microspheres after swelling in ethanol is about 40 microns. At the same time, because the concentric shells of the prepared polymer microspheres are distributed along the radial direction, they have ray-type optical anisotropy (Maltese black cross), and their layere...

Embodiment 2

[0055] Prepare the liquid crystal mixture containing 3g reactive liquid crystal RM257, 6.67g non-reactive liquid crystal E7, 0.33g chiral additive CB15 and 0.1g photoinitiator DMPAP (reactive liquid crystal accounts for 29.7% of liquid crystal mixture), and it is according to the above The steps are to make polymer microspheres, wherein the micropore diameter of the SPG membrane is 10 microns, the continuous phase is water, and the mass percent concentration of surfactant PVA in water is 3.3%. The average particle diameter of prepared chiral polymer microspheres after swelling in ethanol is about 40 microns, micrograph ( Figure 5 (b)) and circular dichroism ( Figure 6 ) also shows that it has a concentric shell structure and dextrorotatory optical activity. At the same time, if Figure 7 As shown, the external SEM image of chiral polymer microspheres shows that it has a porous structure, while its internal SEM image further shows that it has a layered internal structure. ...

Embodiment 3

[0058] Prepare the liquid crystal mixture containing 3g reactive liquid crystal RM257, 6.9g non-reactive liquid crystal E7, 0.1g chiral additive CB15 and 0.1g photoinitiator DMPAP (reactive liquid crystal accounts for the percentage of liquid crystal mixture is 29.7%), it according to above The steps are to make polymer microspheres, wherein the micropore diameter of the SPG membrane is 10 microns, the continuous phase is water, and the mass percent concentration of surfactant PVA in water is 3.0%. The average particle diameter of the prepared chiral polymer microspheres after swelling in ethanol is about 40 microns. Since it uses the same chiral additive as in Example 2, the optical activity of the prepared chiral polymer microspheres is also dextrorotatory. The prepared chiral polymer microspheres were dispersed in deionized water, ethanol and tetrahydrofuran, respectively, Figure 8 It is shown that in different solvents, the chiral polymer microspheres have different swel...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com