A flexible conveying device used in logistics sorting equipment

A conveying device and equipment technology, applied in the direction of conveyors, mechanical conveyors, conveyor objects, etc., can solve the problem that the conveyor roller group cannot actively rotate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

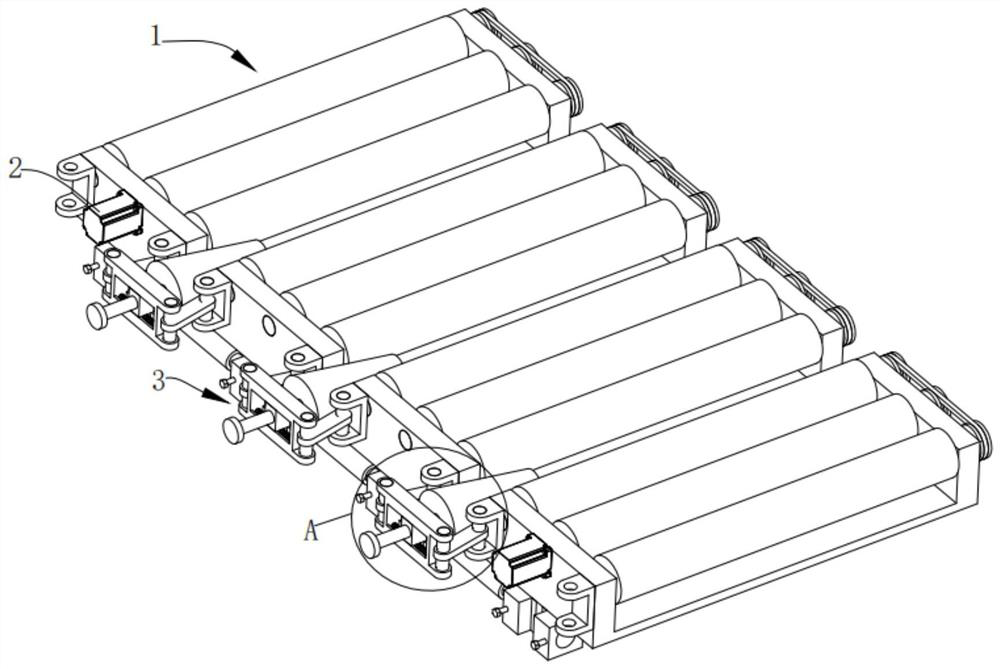

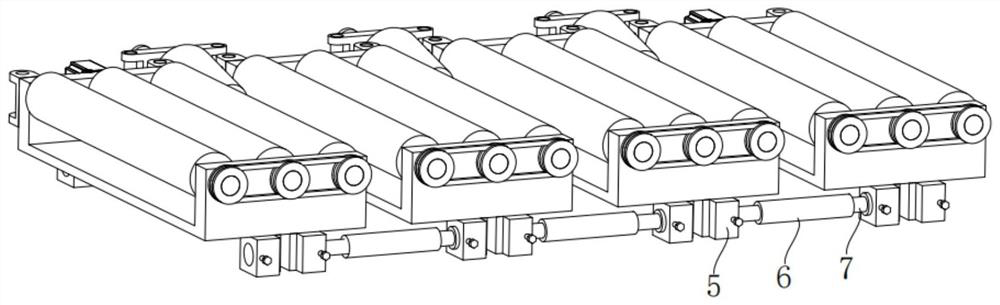

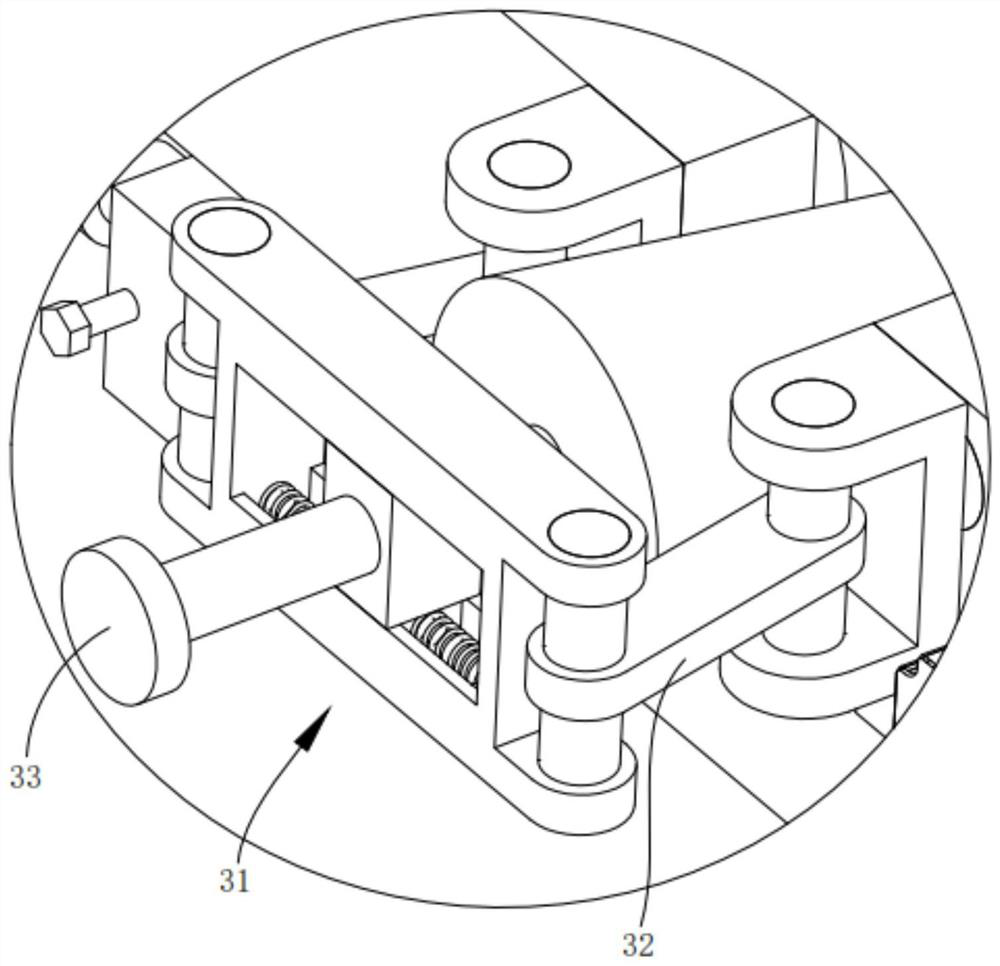

[0026] see Figure 1 to Figure 7 , the present invention provides a technical solution:

[0027] A flexible conveying device for logistics sorting equipment, including a roller conveyor 1, a motor 2, a flexible transmission mechanism 3, a connecting frame 4, a ball rod connecting seat 5, an intermediate rod 6 and a spherical connecting rod 7, wherein:

[0028] Several described roller conveyors 1 are arranged on the same plane, and roller conveyor 1 comprises base plate 11, rubber roller 12, pulley 13 and belt 14, and rubber roller 12 is installed in the base plate 11 by bearing rotation, and rubber roller 12 The end is fixed with a pulley 13, and the belt 14 is sleeved on the pulley 13 to form a belt transmission assembly so that the rubber rollers 12 can rotate synchronously. Several motors 2 are installed on the bottom plate of the roller conveyor 1 at intervals. 11, its power output end is fixedly connected with the rubber roller 12, so each roller conveyor 1 does not nee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com