Empennage assembling equipment

A technology for assembling equipment and tail fins, which is applied in metal processing equipment, metal processing, manufacturing tools, etc., can solve the problems of easy damage to the tail end surface of the missile body, easy screwing of tail fins, and low assembly efficiency, so as to avoid excessive rotation Or it is not rotated in place, it is convenient for alignment and the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

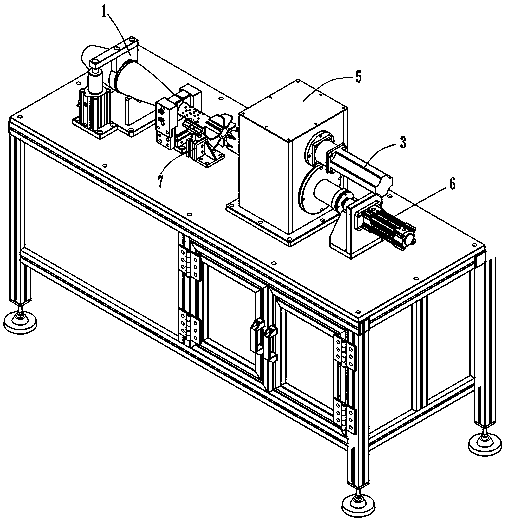

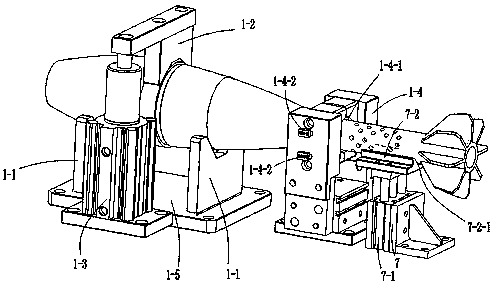

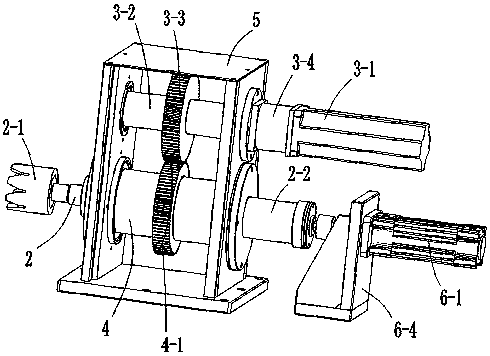

[0034] See Figure 1 to Figure 5 , The empennage assembly equipment of this embodiment includes body positioning tooling 1, empennage support base 7, floating wrench lever 2, driving mechanism 3, transmission sleeve 4, box body 5 and feed assembly 6.

[0035] Both the driving mechanism 3 and the transmission sleeve 4 are arranged in the box body 5 . The projectile positioning tool 1 positions and clamps the projectile. The empennage support base 7 is arranged between the transmission sleeve 4 and the body positioning tool 1, and the top of the empennage support base 7 is used for placing the empennage. The driving mechanism 3 drives the transmission sleeve 4 to rotate in the circumferential direction. The floating wrench rod 2 is slidably arranged in the transmission sleeve 4 in the axial direction, and is fixed relative to the transmission sleeve 4 in the circumferential direction. The front end of the floating wrench bar 2 is provided with an empennage wrench 2-1. The fl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com