Vertical drilling machine

A drilling rig and vertical technology, applied in the direction of boring/drilling, drilling/drilling equipment, metal processing equipment, etc., can solve the problems of inconvenient operation for operators and hidden dangers in production safety, and achieve simplified overall structure and reduced manufacturing costs. Cost, the effect of overcoming hidden dangers in production safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] Below in conjunction with accompanying drawing, technical scheme of the present invention is described in further detail:

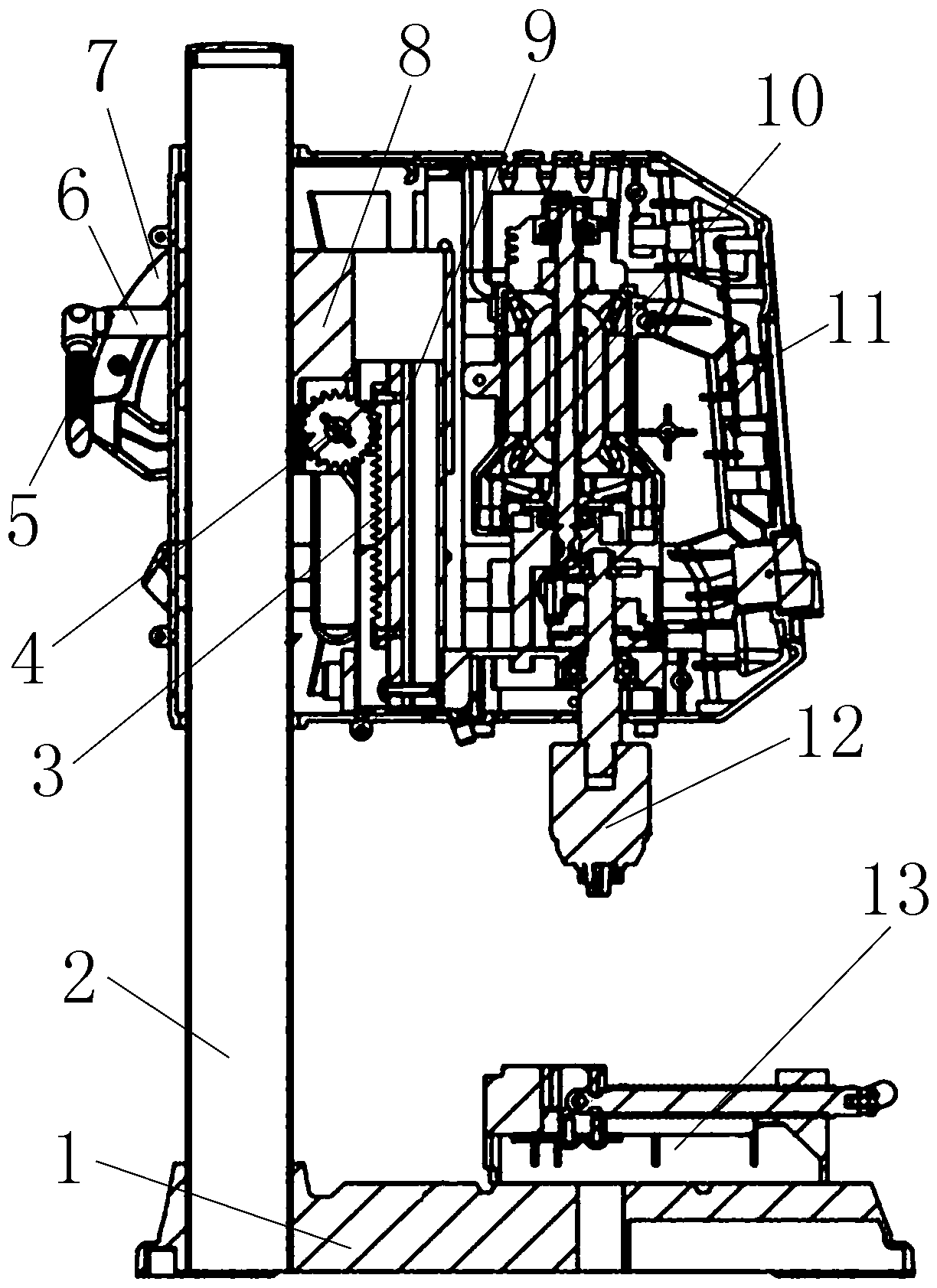

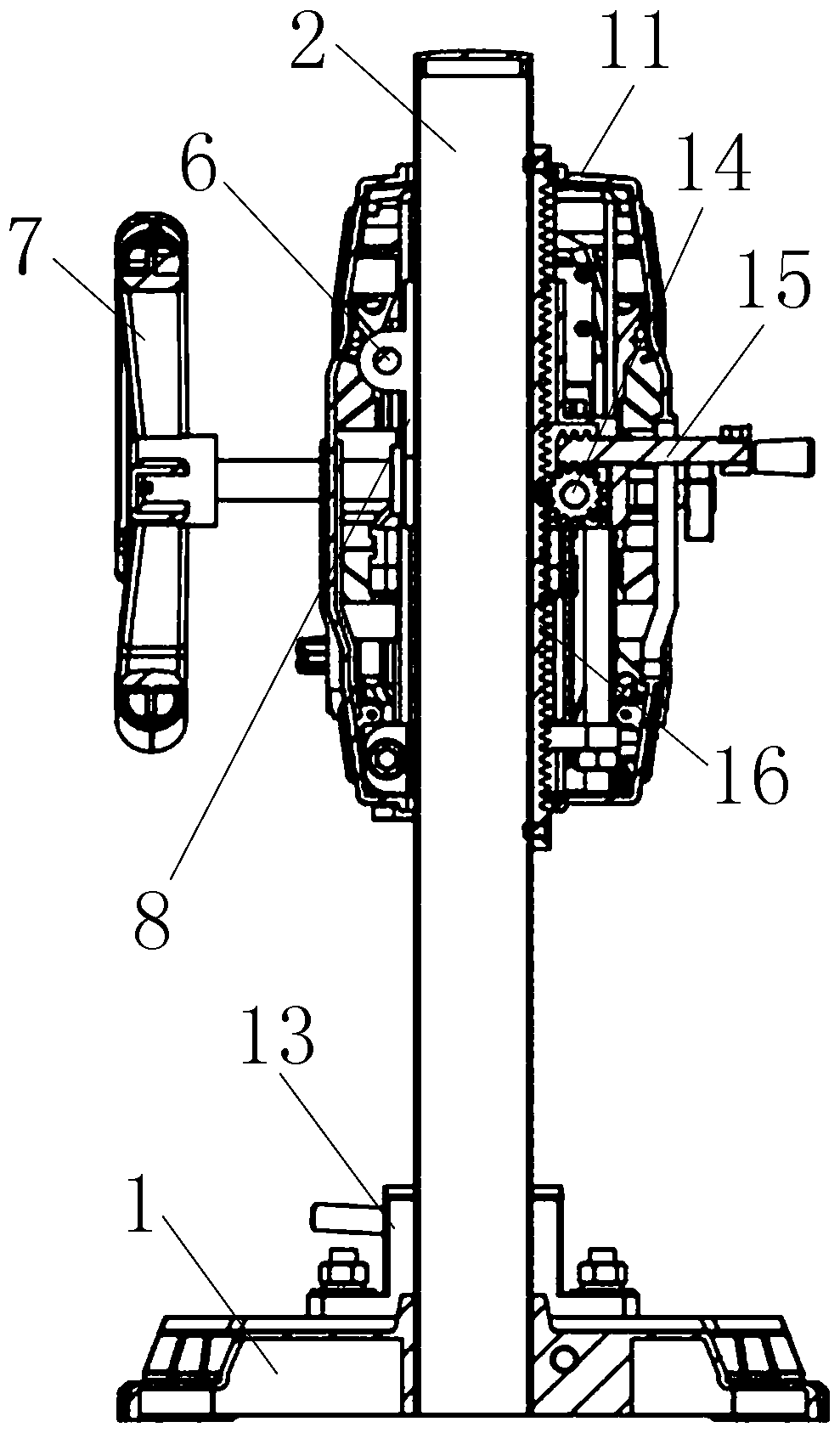

[0014] like figure 1 and figure 2 As shown, the present invention discloses a vertical drilling machine, which includes a column 2 , a base 1 , a driving device 10 and a drill chuck 12 . The drill chuck 12 is arranged on the driving device 10 , and the driving device 10 is provided with a housing 11 . The column 2 is arranged on the base 1 . The above-mentioned vertical drilling machine also includes a drilling lifting mechanism, and the drilling lifting mechanism includes a mechanism box 8, a lifting rack 3, a gear 4, a lifting shaft 9, a spring and a connecting seat. One side of mechanism box 8 is provided with through hole, and this through hole matches with described column 2, and this through hole is sleeved on the column 2, and this through hole side is provided with opening, and the both sides of opening is respectively provided with pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com