Compound parallel-connection four-foot wall climbing mechanism

A wall-climbing and paralleling technology, applied in the direction of motor vehicles, transportation and packaging, can solve the problems of tipping, affecting the adsorption and crawling ability and posture stability, and sliding of wall-climbing robots, so as to achieve the effect of expanding the application range.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

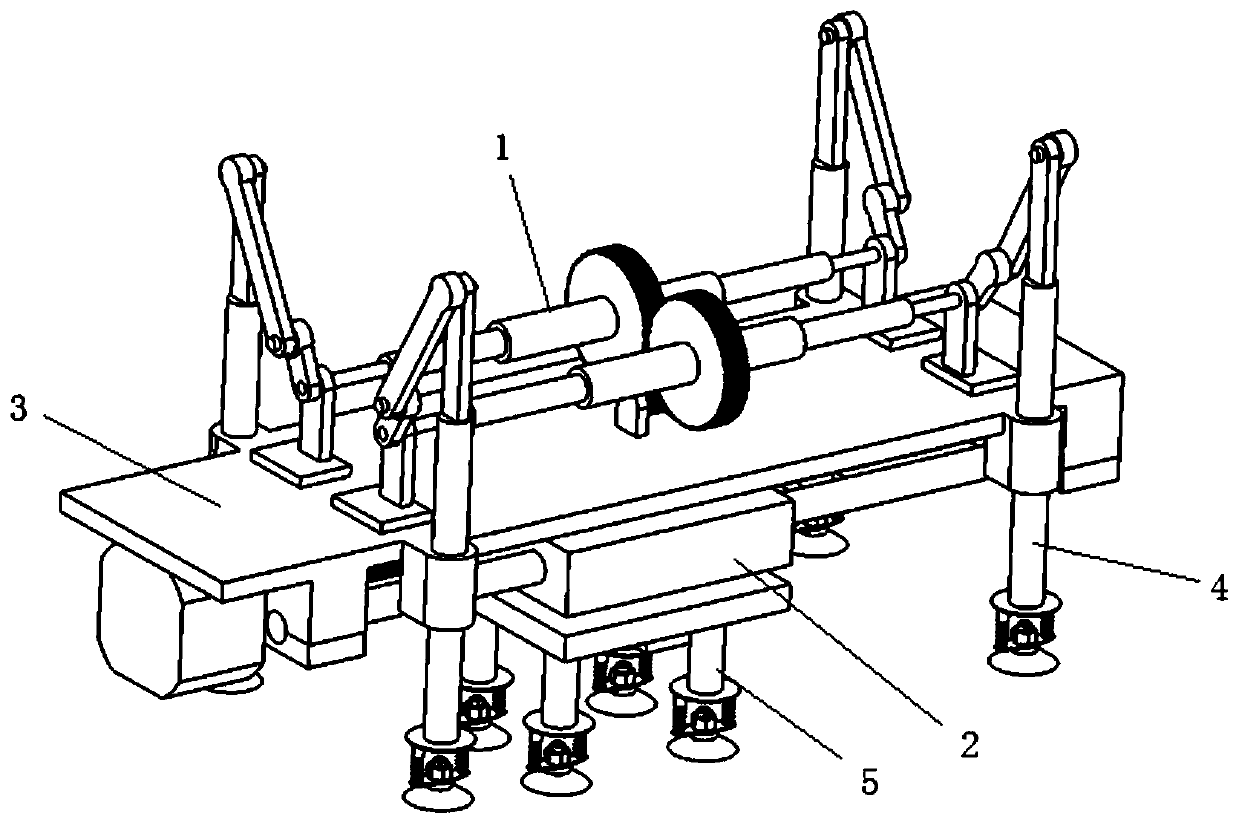

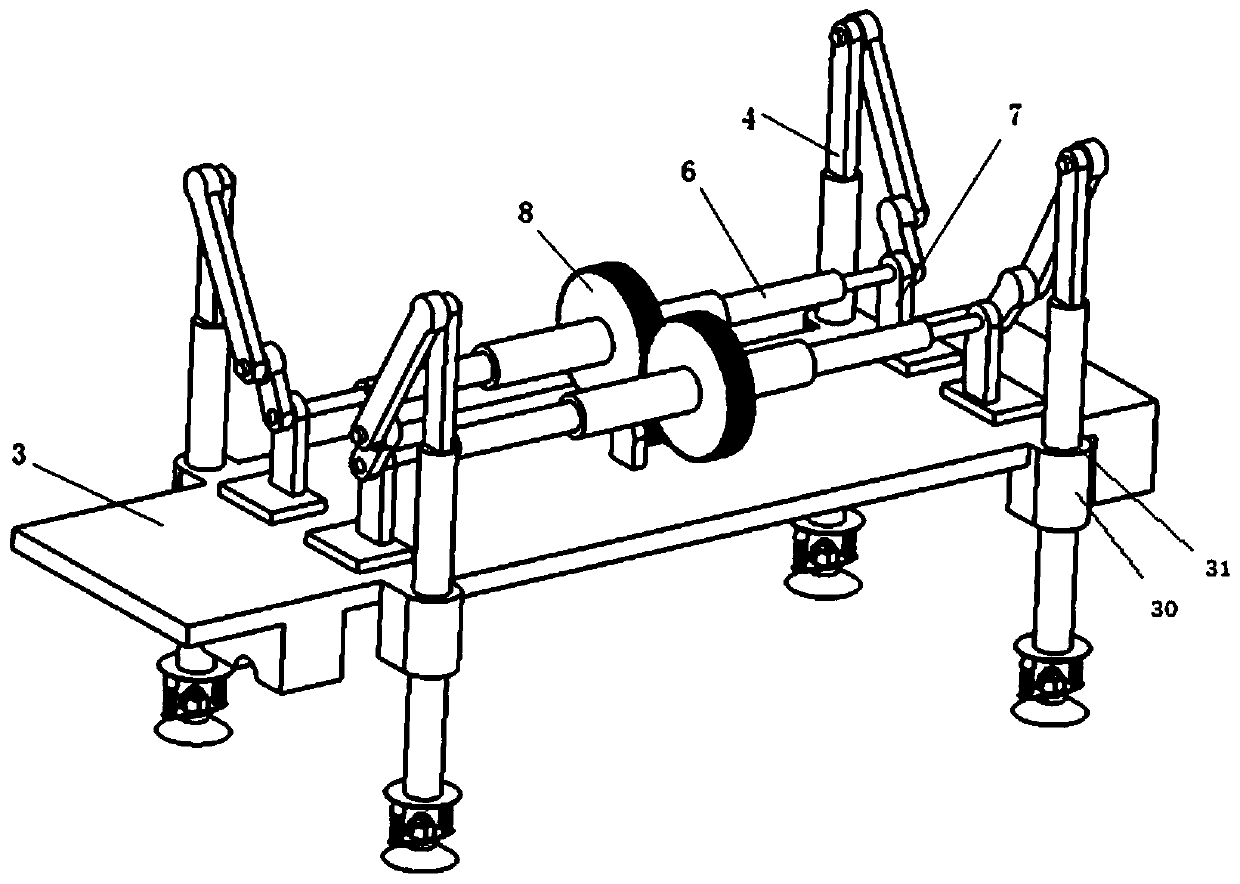

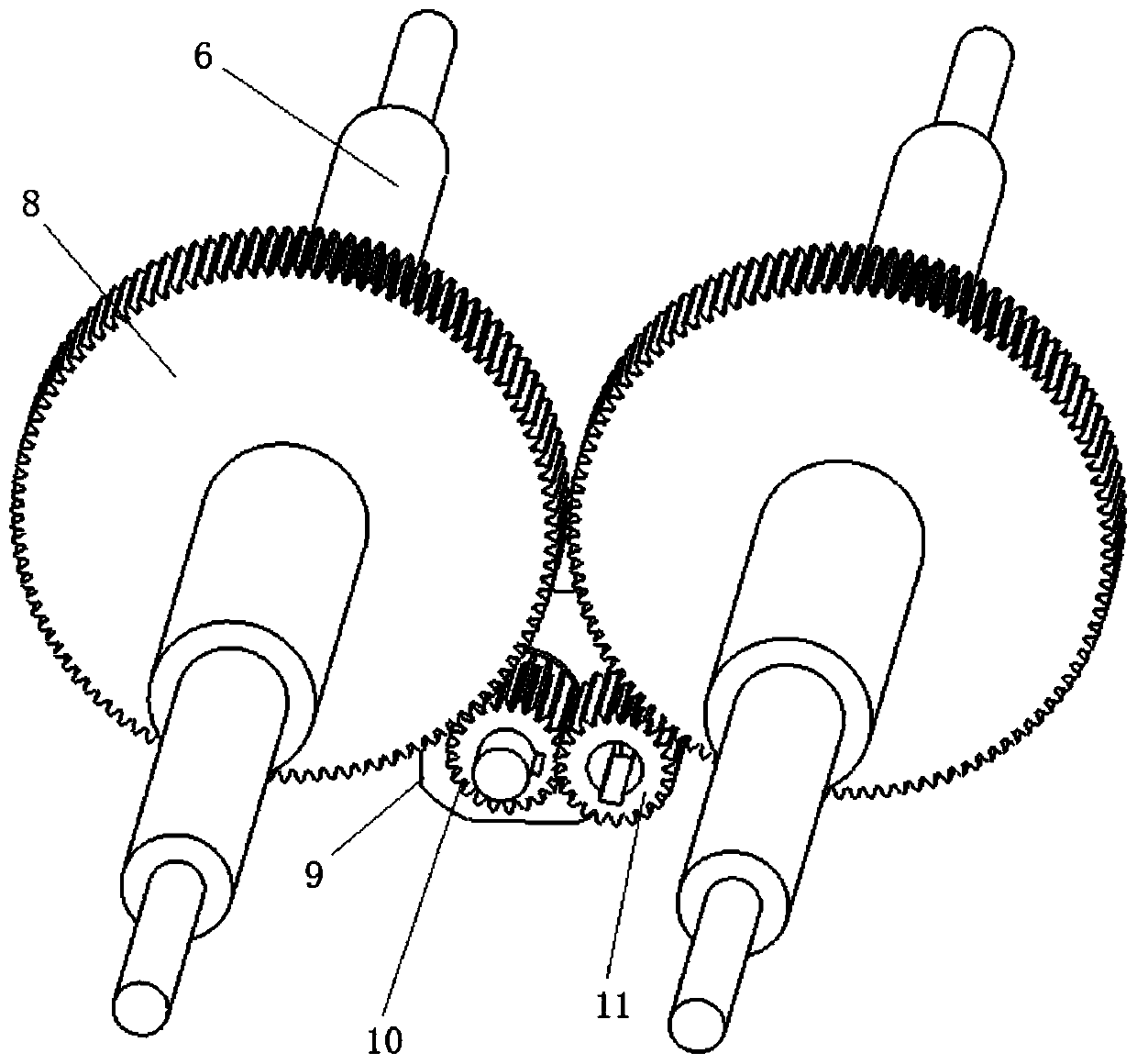

[0117] Such as Figure 1 to Figure 8g As shown, the present invention provides a composite parallel quadruped wall-climbing mechanism, comprising a main wall-climbing device 1 and an auxiliary wall-climbing device 2;

[0118] Main climbing device 1 comprises:

[0119] Fuselage upper panel 3;

[0120] Four telescopic foot assemblies 4, the four telescopic foot assemblies 4 are slidably connected to both sides of the upper panel 3 of the fuselage;

[0121] The main drive assembly, the main drive assembly drives the four telescopic foot assemblies 4 to perform periodic telescopic movements synchronously;

[0122] Auxiliary wall climbing device 2 includes:

[0123] Four auxiliary foot assemblies 5, the four auxiliary foot assemblies 5 are slidably connected to the bottom of the upper panel 3 of the fuselage;

[0124] Auxiliary drive assembly, the auxiliary drive assembly drives four auxiliary foot assemblies 5 to perform periodic reciprocating motion relative to the main wall ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com