A Method for Gradient Yarns Based on Discrete Gradient Chromatography Based on Coupling and Mixing Spinning of Four Primary Color Fibers

A technology of four primary colors and fibers, applied in the directions of fiber mixing, fiber processing, yarn, etc., can solve the problems such as the inability to mix two colors of fibers, the inability to accurately control the mixing ratio of different color fibers, and the color gradient.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0060] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings.

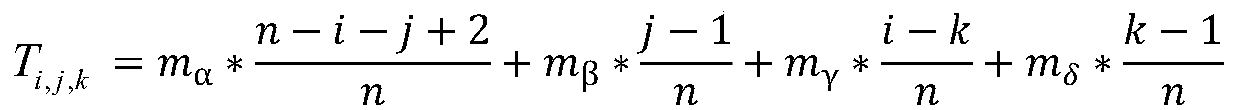

[0061] The present invention designs a method for coupling and mixing fibers of four primary colors based on discrete gradient color spectrum to produce gradient yarn, which is used to obtain fibers of four colors, based on the combination of different coupling mass ratios, and the coupling fiber chromatography. Corresponding coupling fibers, such as figure 1 As shown, it specifically includes the following steps.

[0062] Step A. For the coupling mass ratio of the first color fiber α, according to the preset number of decrements n, decrease in equal proportions from 100% to 0%, and obtain the coupling mass ratio of the α color fiber under each descending sequence number, and The general formula for obtaining the coupling mass ratio corresponding to the descending sequence number of the α-color fiber is as follows:

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com