Boring and milling device with welding gun feeding function

A technology of feed function and welding torch, which is applied in the field of milling machines, can solve the problems of inconvenient operation, lack of welding repair, cutting but not welding repair, etc., and achieve the effect of easy popularization and application, convenient adjustment and control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

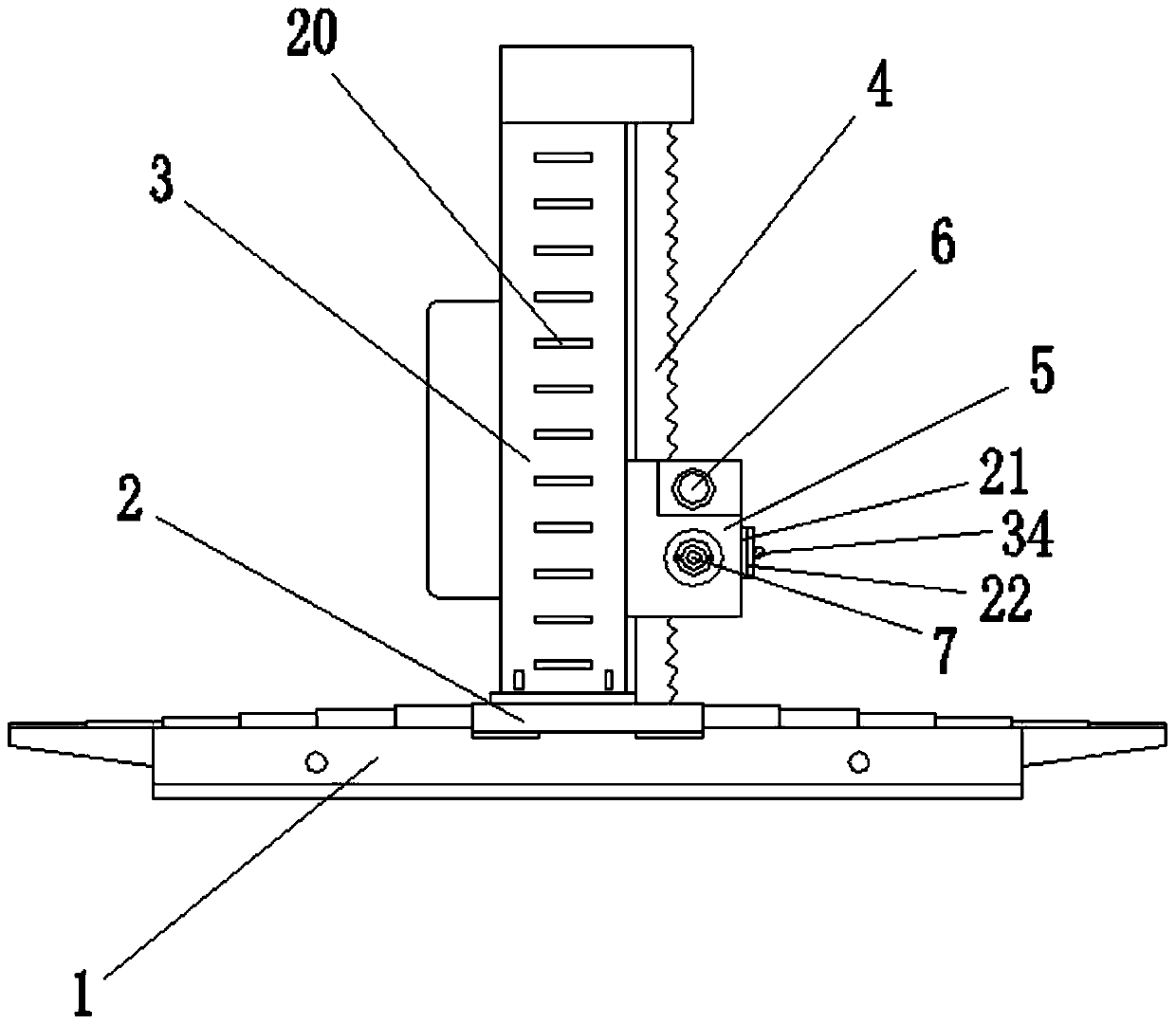

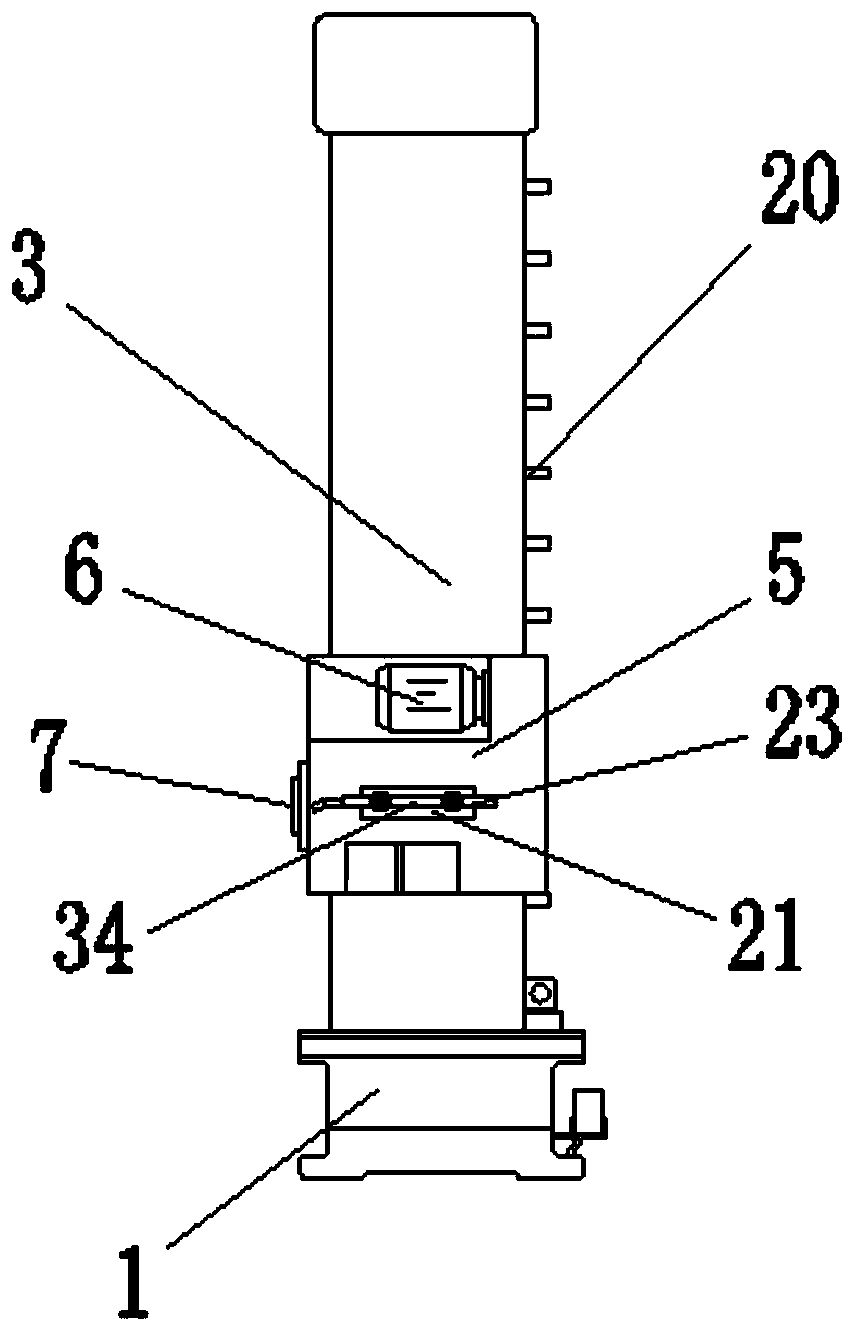

[0035] Example: such as Figure 1-7 Shown, a kind of milling device with welding torch feeding function, comprising:

[0036] Base 1, the top of the base 1 is slidably mounted with a moving frame 2, the top of the moving frame 2 is fixedly connected with a stand 3, and the right side of the stand 3 is fixedly equipped with a lifting rail 4, and the lifting A lifting frame 5 is movable installed on the rail 4; the milling cutter can control the position of the milling cutter cutting and welding torch by adjusting the moving frame and lifting.

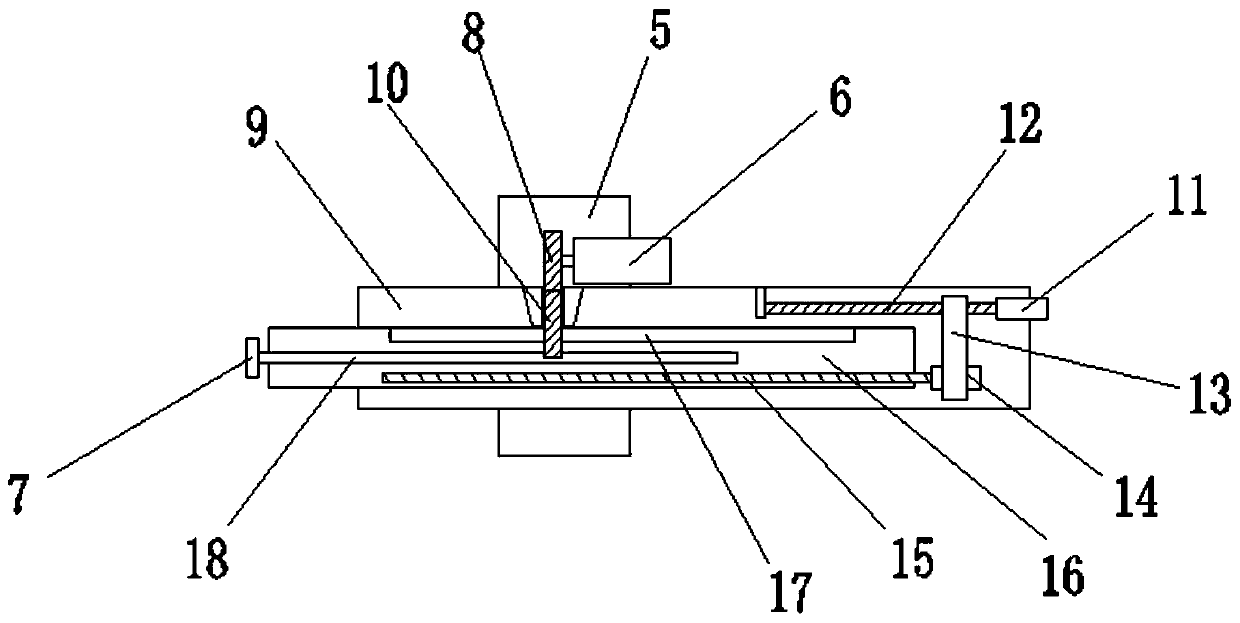

[0037] The top of the lifting frame 5 is fixedly installed with a first motor 6, the left side of the first motor 6 is fixedly connected with a driving gear 8, and the middle part of the lifting frame 5 is fixedly equipped with an adjustment warehouse 9, and the adjustment warehouse 9 A transmission gear 10 is installed in rotation on the top of the inner cavity, and the drive gear 8 and the transmission gear 10 are meshed with each oth...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap