Cloth pulling wheel device capable of being slightly adjusted for sewing machine

A mop wheel and sewing machine technology, applied to sewing machine components, sewing equipment, cloth feeding mechanism, etc., can solve the problems of large volume, many pipelines, troublesome installation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] Hereinafter, the present invention will be further described in detail with reference to the accompanying drawings and specific embodiments.

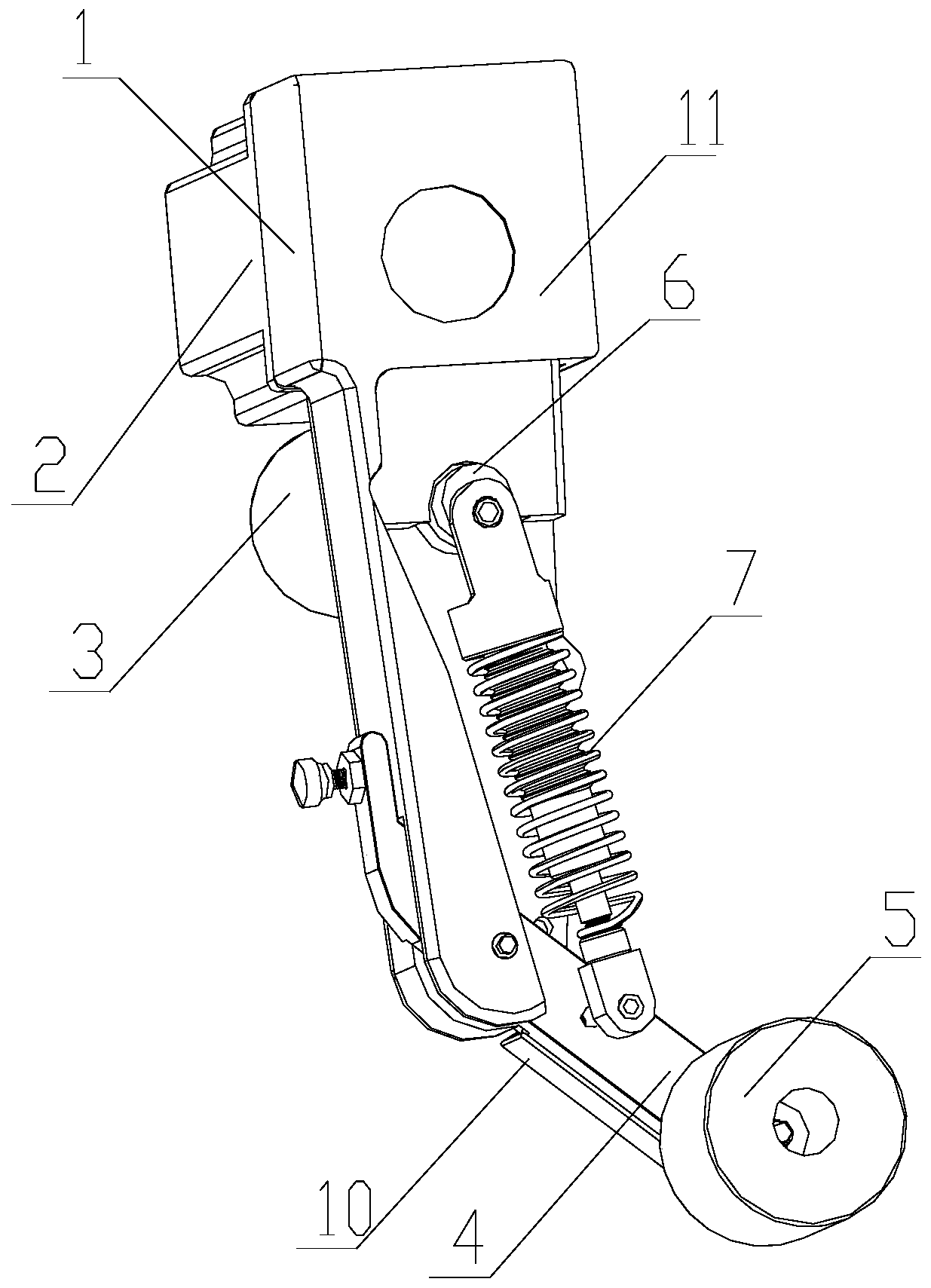

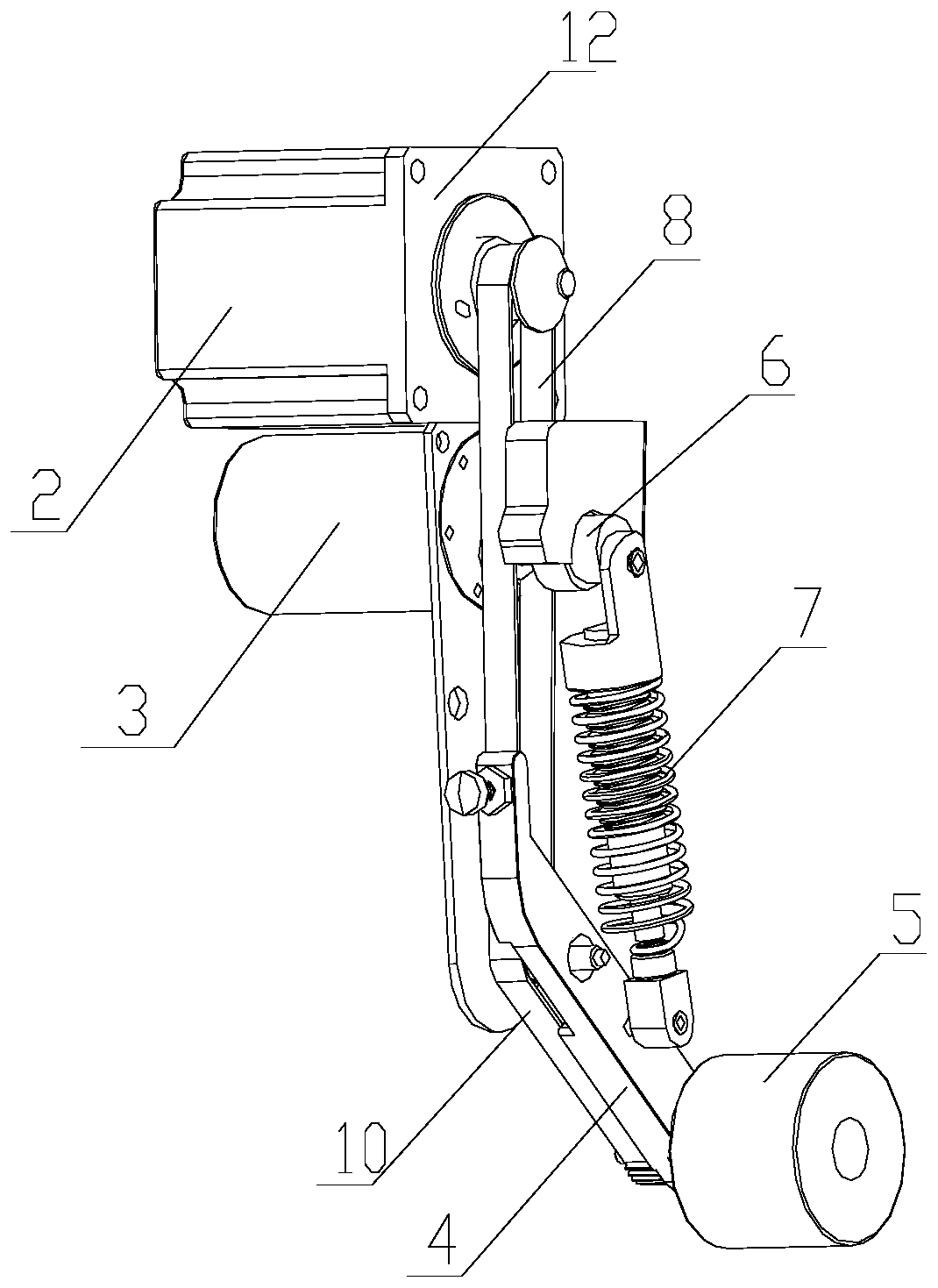

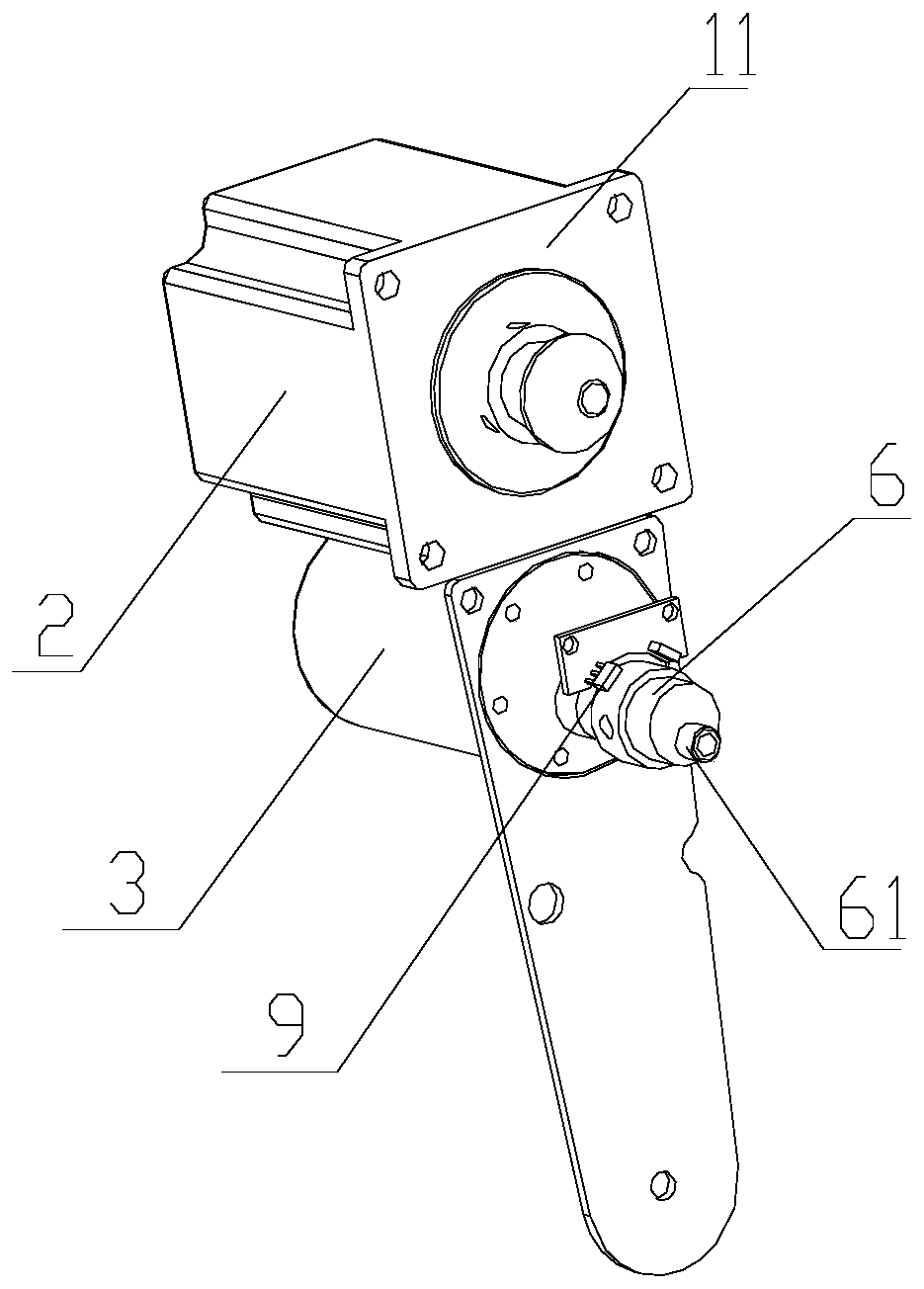

[0023] Such as figure 1 , figure 2 and Figure 4 As shown, the finely adjustable sewing machine mop wheel device of the present invention includes a mounting bracket 1, a first motor 2, a fine-tuning connecting rod 4, a tug wheel 5, a connecting mechanism 7 and a belt drive 8, and the mounting bracket 1 includes a mounting plate 12 and a housing 11, The mounting plate 12 is fixedly connected to the shell 11, the bottom of the shell 11 is provided with a gap, the fine-tuning link 4 is inserted into the gap of the shell 11, and the mounting plate 12 and the fine-tuning link 4 are pivotally connected, and the fine-tuning link The upper end of the rod 4 is formed with a bent tail, the tail is located outside the casing 11, and the tail is provided with a screw mounting hole, and a screw is fixed in the screw mounting hole, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com