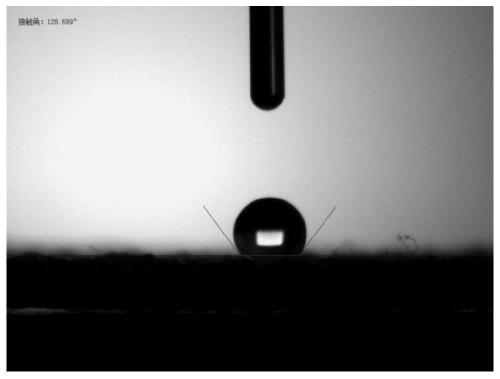

Platinum-charcoal/rare earth oxide composite-phase hydrophobic catalyst, and preparation method and application thereof

A rare earth oxide and composite phase technology, applied in metal/metal oxide/metal hydroxide catalysts, physical/chemical process catalysts, chemical instruments and methods, etc., can solve problems such as low catalytic performance, and achieve simple, The effect of design science, high practical value and promotion value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

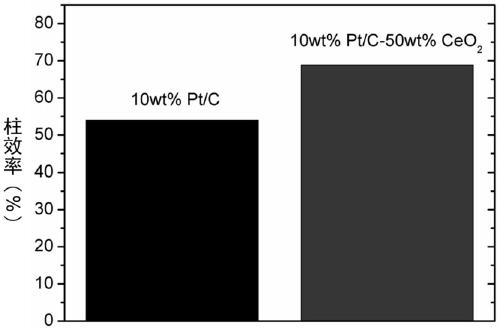

Embodiment 1

[0035] This embodiment discloses the preparation method of the platinum carbon / rare earth oxide composite phase hydrophobic catalyst of the present invention, specifically:

[0036] Step 1. Preparation of platinum carbon catalyst: dissolving chloroplatinic acid hydrate in deionized water to form an aqueous solution with a platinum ion concentration of 0.1mol / L;

[0037] A certain amount of XC-72 carbon black was weighed, and then an aqueous solution of chloroplatinic acid was added according to the loading amount of platinum in the platinum carbon as 10 wt%, and fully stirred. After the sample was preliminarily dried, it was further dried in a vacuum oven at 110°C for 12 hours. Next, the dried sample is subjected to reduction treatment, and the treatment condition is 10% H at a flow rate of 300ml / min. 2Heating to 400°C at 10K / min under the / Ar mixed gas atmosphere, keeping the temperature constant for 2h, and then cooling to room temperature with the furnace to prepare the pl...

Embodiment 2

[0043] This embodiment discloses the preparation method of the platinum carbon / rare earth oxide composite phase hydrophobic catalyst of the present invention, specifically:

[0044] Step 1. Preparation of platinum carbon catalyst: dissolving chloroplatinic acid hydrate in deionized water to form an aqueous solution with a platinum ion concentration of 0.01mol / L;

[0045] A certain amount of XC-72 carbon black was weighed, and then an aqueous solution of chloroplatinic acid was added according to the loading amount of platinum in the platinum carbon at 0.1 wt%, and fully stirred. After the sample was preliminarily dried, it was further dried in a vacuum oven at 110°C for 12 hours. Next, the dried sample is subjected to reduction treatment, and the treatment condition is 10% H at a flow rate of 300ml / min. 2 Heating to 400°C at 10K / min under the / Ar mixed gas atmosphere, keeping the temperature constant for 2h, and then cooling to room temperature with the furnace to prepare the...

Embodiment 3

[0051] This embodiment discloses the preparation method of the platinum carbon / rare earth oxide composite phase hydrophobic catalyst of the present invention, specifically:

[0052] Step 1. Preparation of platinum carbon catalyst: dissolving chloroplatinic acid hydrate in deionized water to form an aqueous solution with a platinum ion concentration of 0.05mol / L;

[0053] A certain amount of XC-72 carbon black was weighed, and then an aqueous solution of chloroplatinic acid was added according to the loading amount of platinum in the platinum carbon as 20 wt%, and fully stirred. After the sample was preliminarily dried, it was further dried in a vacuum oven at 110°C for 12 hours. Next, the dried sample is subjected to reduction treatment, and the treatment condition is 10% H at a flow rate of 300ml / min. 2 Heating to 400°C at 10K / min under the / Ar mixed gas atmosphere, keeping the temperature constant for 2h, and then cooling to room temperature with the furnace to prepare the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com