Hard bouillon tablet

A broth and tablet technology, applied in the field of hard broth tablets, can solve the problems of hard broth tablets and loss of breakability after hardening

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1 to 5

[0087] Different types of fat have been tested.

[0088]

[0089]

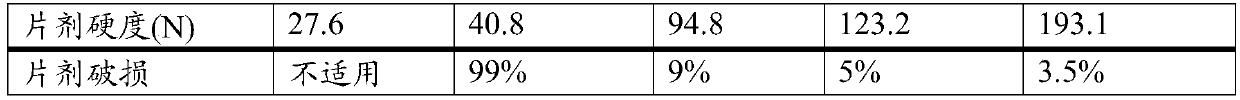

[0090] Examples 1 to 5 show that the induction period, slip melting point and flowability of the broth powder are improved when fats with higher SFA content are used. The induction period of the fat, the slip melting point of the fat and the fluidity of the broth powder are greatly improved when the saturated fat content is higher than 48 wt% fat. In addition, these recipes show that the broth powder does not form lumps, thus ensuring accurate dosing and therefore tableting precision. Comparative Examples 1 and 2 have lower tablet hardness because the inventive chicken fat has a total saturated fat content of 48 to 72% by weight (based on the weight of total fat), fatty acid C16:0 at 41 to 49% by weight range (by weight of total fat), fatty acid C18:0 was in the range of 13 to 17% by weight (by weight of total fat), which resulted in a tablet breakage rate of less than 9% during tablet wrapping. The ta...

Embodiment 6

[0092] Example 6: Measurement of Oil Release in Broth Tablets

[0093] Oil evolution was quantified by placing bouillon tablets horizontally on Schleicher Schuell 90mm round filter paper (Whatman, UK). The samples were then stored for 4 days in a climate chamber ICH110 (Memmert GmbH+Co. KG, Germay) set at 30% relative humidity (RH), 40% fan speed, and temperatures of 23°C, 30°C and 37°C.

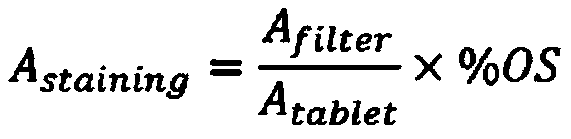

[0094] After storage, images of the filter papers were acquired using a DigiEye device (Verifide, UK) equipped with a Nikon D90 and a Nikon 35mm f / 2 lens. Set DigiEye lighting to Diffuse and set the lens aperture to f / 8. The severity of the oil contamination (A staining ) is quantified as the area of the filter paper covered with oil compared to the contact area between the filter paper and the broth tablet:

[0095]

[0096] where A filter is the area of the filter paper (6.36·10 -3 m 2 ), A tablet is the contact area between the filter paper and the broth tablet (7.13 10 -...

Embodiment 7

[0100] Example 7: Dissolution time in hot water

[0101] One hard bouillon tablet (10 g) was dissolved in 500 ml of water at a temperature of 85°C and continuously stirred with a 60 mm magnetic stirrer at 60 rpm. Repeat the measurement 6 times.

[0102]

[0103] These dissolution times are comparable. Only Example 1, which had the smallest tablet hardness, dissolved faster. However, the increased SFA and hardness of the tablets did not prolong the dissolution times shown in Examples 2-5.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com