Material cooling turnover tool

A technology of tooling and materials, applied in the field of material cooling turnover tooling, can solve the problems of high labor intensity and slow production efficiency of workers, and achieve the effect of avoiding manual transfer and reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

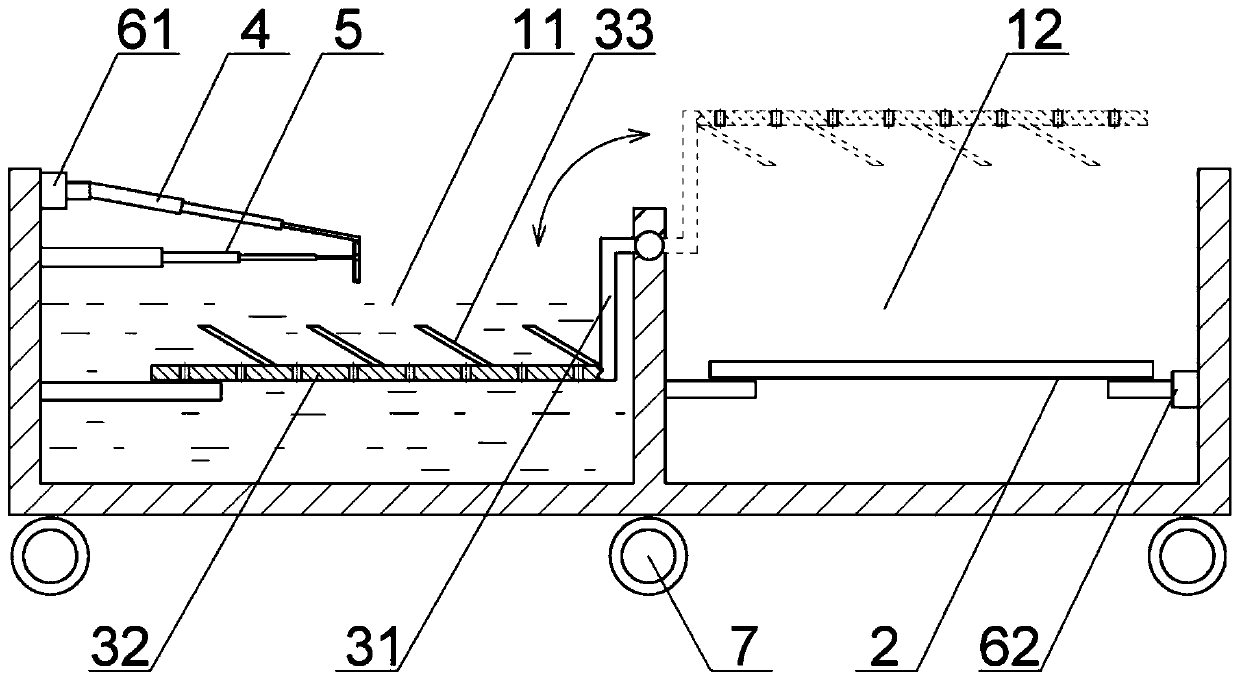

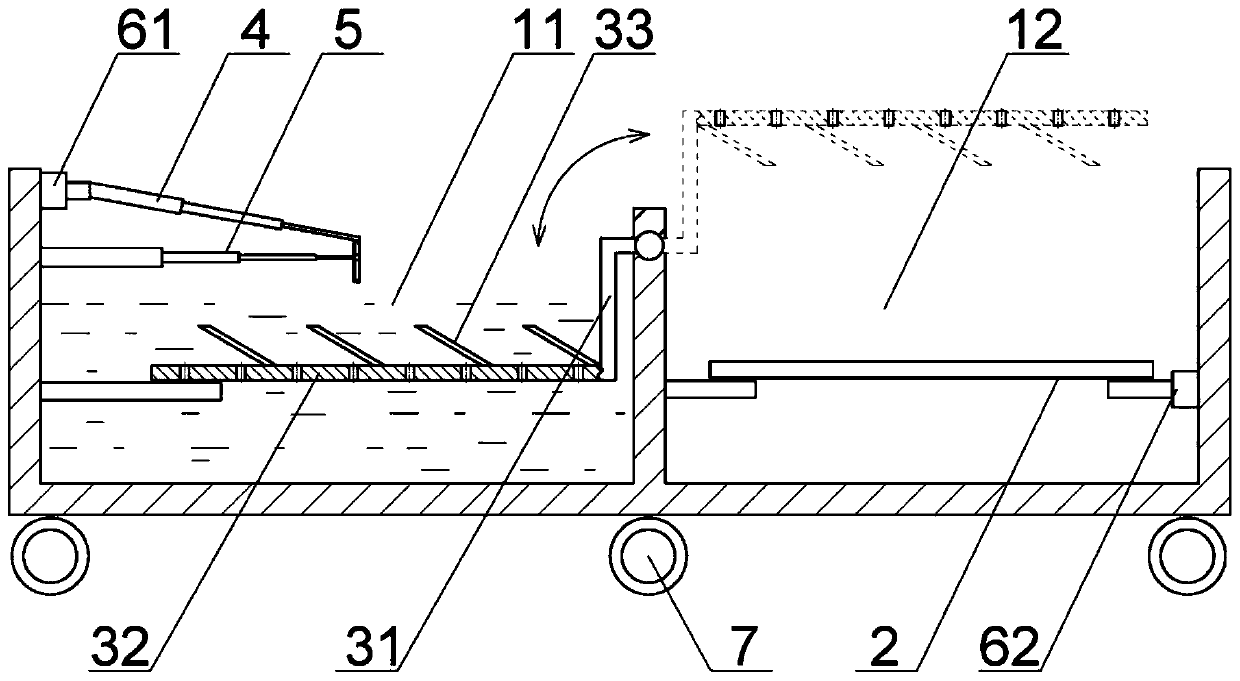

[0018] Such as figure 1 as shown, figure 1 It is a structural schematic diagram of a material cooling turnover tool proposed by the present invention, and the motor is not shown.

[0019] refer to figure 1 , a material cooling turnover tool proposed by the present invention, including a tool body, a tray assembly, a motor and a draining rack 2;

[0020] The tool body is provided with a cooling pool 11 and a draining pool 12, the cooling pool 11 and the draining pool 12 are adjacent to each other, there is only one layer of partition between the cooling pool 11 and the draining pool 12, and the cooling pool 11 is used to accommodate cooling Liquid and undertake rubber seals;

[0021] The tray assembly includes a connecting frame 31, a tray 32 and an inclined plate 33. The edge of the tray 32 is fixedly connected with the connecting frame 31. The connecting frame 31 is rotatably mounted on the partition. The rotating plane of the connecting frame 31 is parallel to the vertica...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com