Straw composting process, organic fertilizer and preparation method thereof

An organic fertilizer and a technology for organic fertilizer, which are applied in the fields of organic fertilizer and its preparation, and straw composting technology, can solve the problems of large environmental pollution, poor decomposing degree, low utilization rate of straw biomass energy, etc., so as to reduce production costs and improve production. The effect of efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

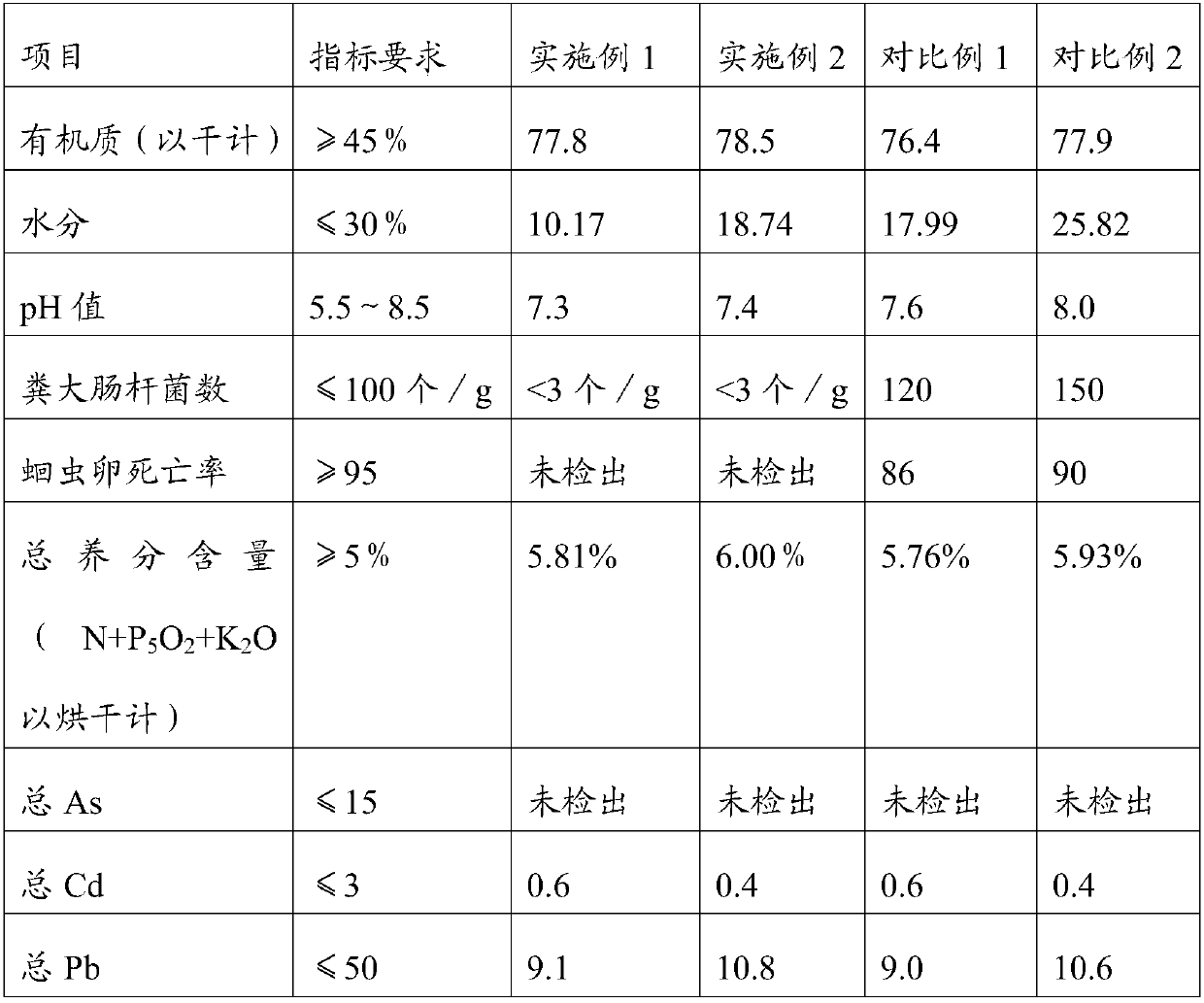

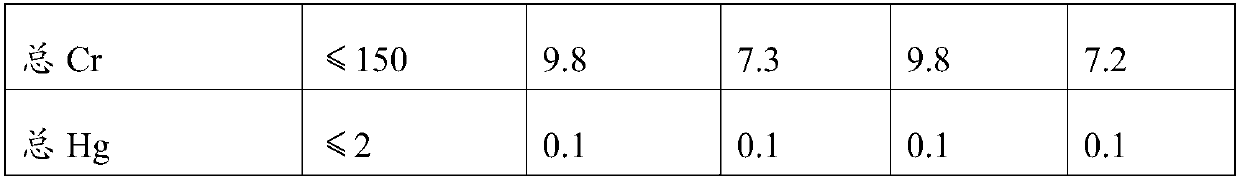

Examples

Embodiment 1

[0025] This embodiment provides a straw composting process, comprising the following steps:

[0026] S1, knead and crush the corn stalks until the length is 8cm-15cm, mix according to the weight ratio of straw and pig manure 56:44, control the moisture content to 60%, the carbon-nitrogen ratio to 28:1, and use fly ash to adjust the pH value to be weak Alkaline, with a total weight of 1000Kg, to obtain a mixed material. Compared with traditional cutting crushing, kneading crushing is not only efficient, but also more economical.

[0027] S2, put the mixed material in the compost bin, seal the compost bin, rapidly raise the temperature of the mixed material in the compost bin to 70±2°C with the help of residual oxygen in the air in the compost bin, and react for 2 days to obtain the primary material. This step treatment can not only eliminate miscellaneous bacteria and complete disinfection, but also allow the straw to swell and soften at high temperature, better absorb water, ...

Embodiment 2

[0032] This embodiment provides a straw composting process, comprising the following steps:

[0033] S1, crush the wheat straw to a length of 8cm-15cm, mix it according to the weight ratio of straw and cow dung at 1:1, control the moisture content to 55%, and the carbon-to-nitrogen ratio to 30:1, and use fly ash to adjust to weak alkaline , with a total weight of 1000Kg to obtain a mixed material. Compared with traditional cutting crushing, kneading crushing is not only efficient, but also more economical.

[0034] S2, put the mixed material in the compost bin, seal the compost bin, rapidly raise the temperature of the mixed material in the compost bin to 70±2°C with the help of residual oxygen in the air in the compost bin, and react for 2 days to obtain the primary material. This step treatment can not only eliminate miscellaneous bacteria and complete disinfection, but also allow the straw to limit expansion and soften at high temperature, better absorb water, and facilita...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com