Multiple clutch for a motor vehicle, particularly for a hybrid drive of a motor vehicle

A hybrid drive and drive device technology, applied in mechanical drive clutches, non-mechanical drive clutches, fluid drive clutches, etc., can solve the problems of high cost, consumption, increase manufacturing cost, etc., reduce manufacturing cost, simplify assembly cost, and reduce manufacturing cost. cost reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

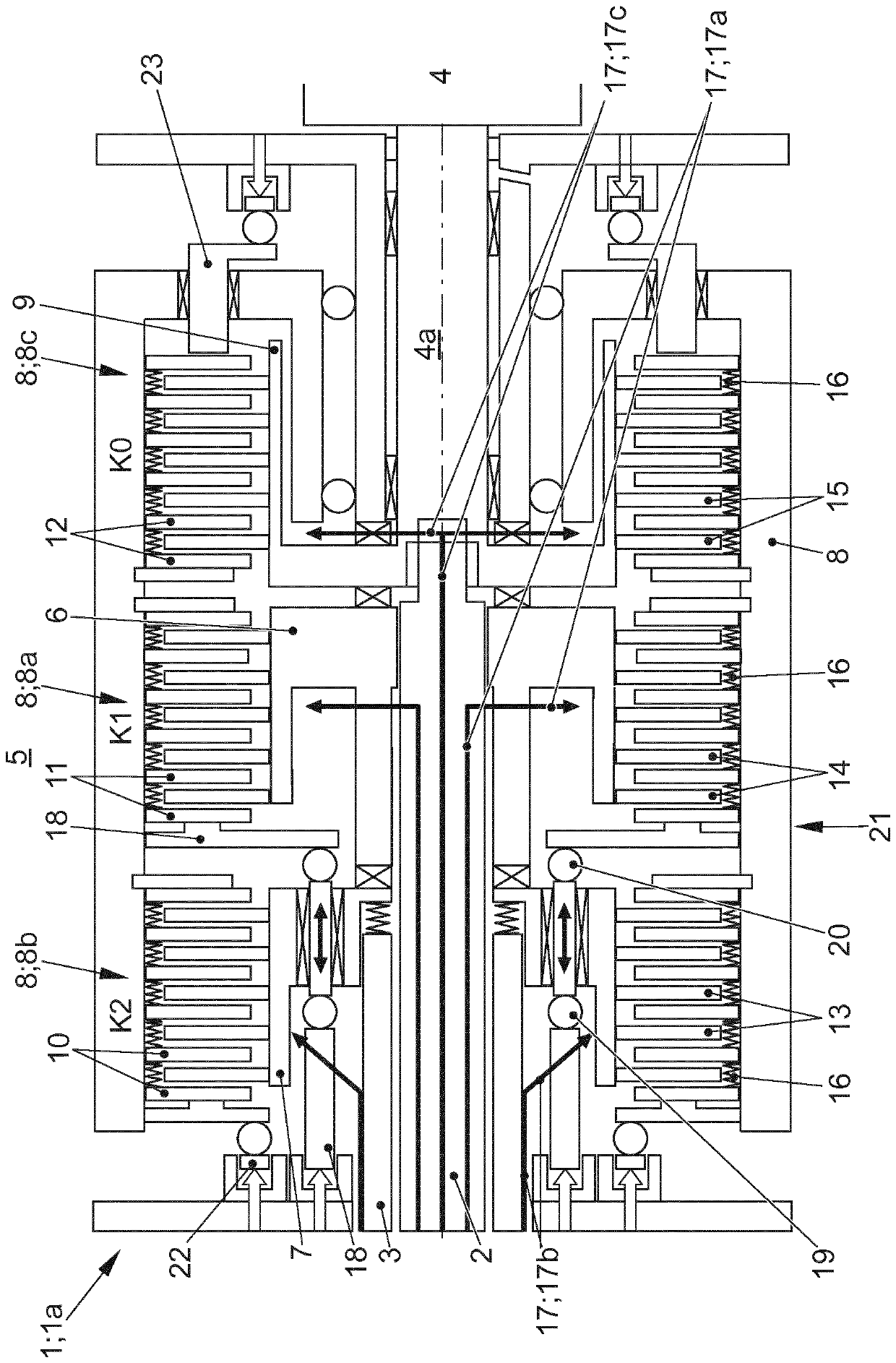

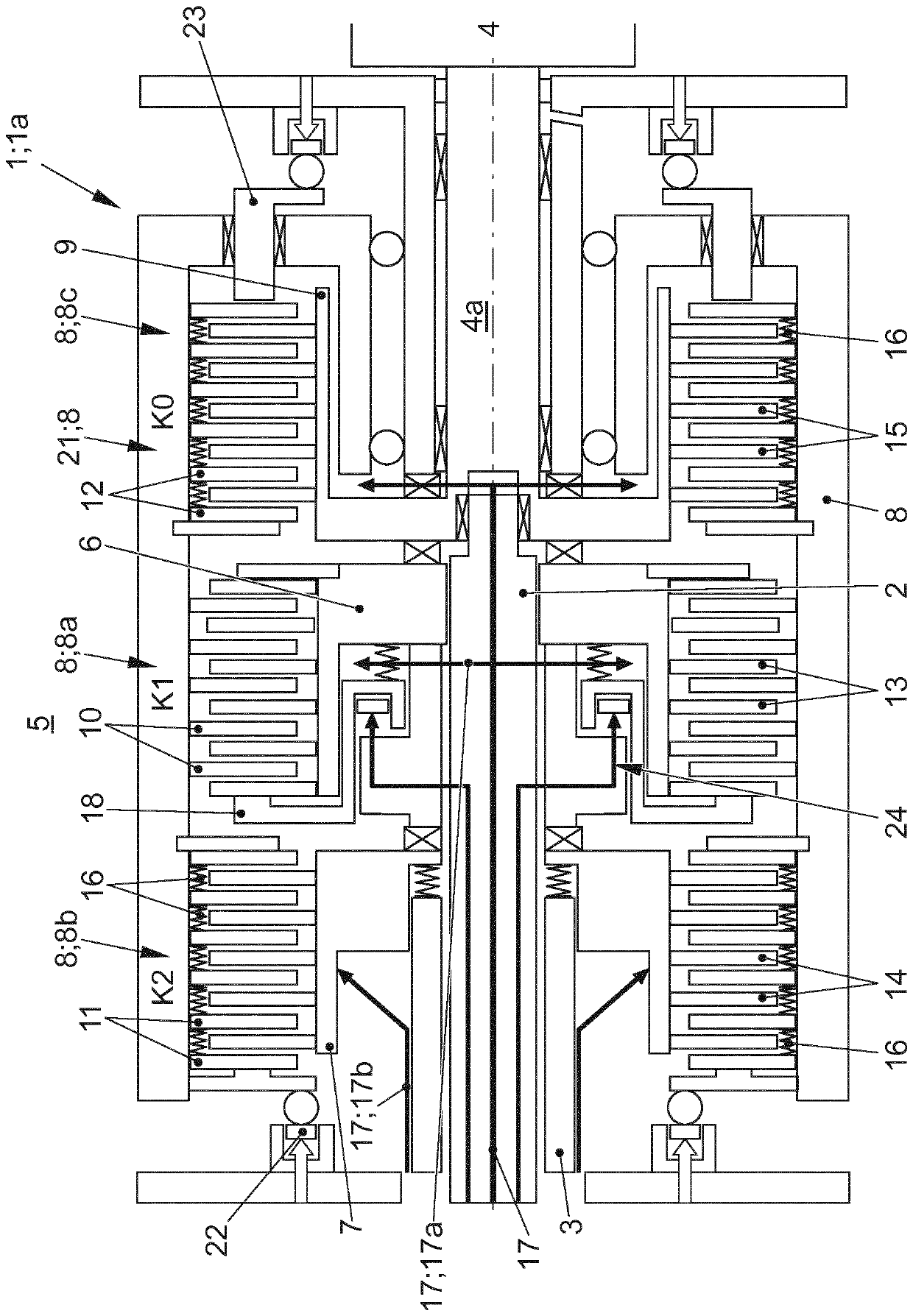

[0023] figure 1 and figure 2 A multiple clutch 1 for a motor vehicle not shown in more detail, in particular for a hybrid drive of a motor vehicle not shown in more detail, is shown at least partially schematically in section. The following implementation basically involves the figure 1 and figure 2 Two implementations are shown in .

[0024] The multiple clutch 1 has at least a first separating clutch K1 , a second separating clutch K2 and a third separating clutch K0 . The first, second and third separating clutches K1 , K2 and K0 are in particular designed as multi-disk clutches or friction clutches.

[0025] The multiple clutch 1 shown here is in particular designed or embodied as a double clutch 1 a with the addition of a so-called “K0 clutch” as a third separating clutch. The multiple clutch 1 shown here or the double clutch 1a shown with an added "K0 clutch" is used in particular to actuate the two transmission input shafts 2 or 3 of a double clutch transmission ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com