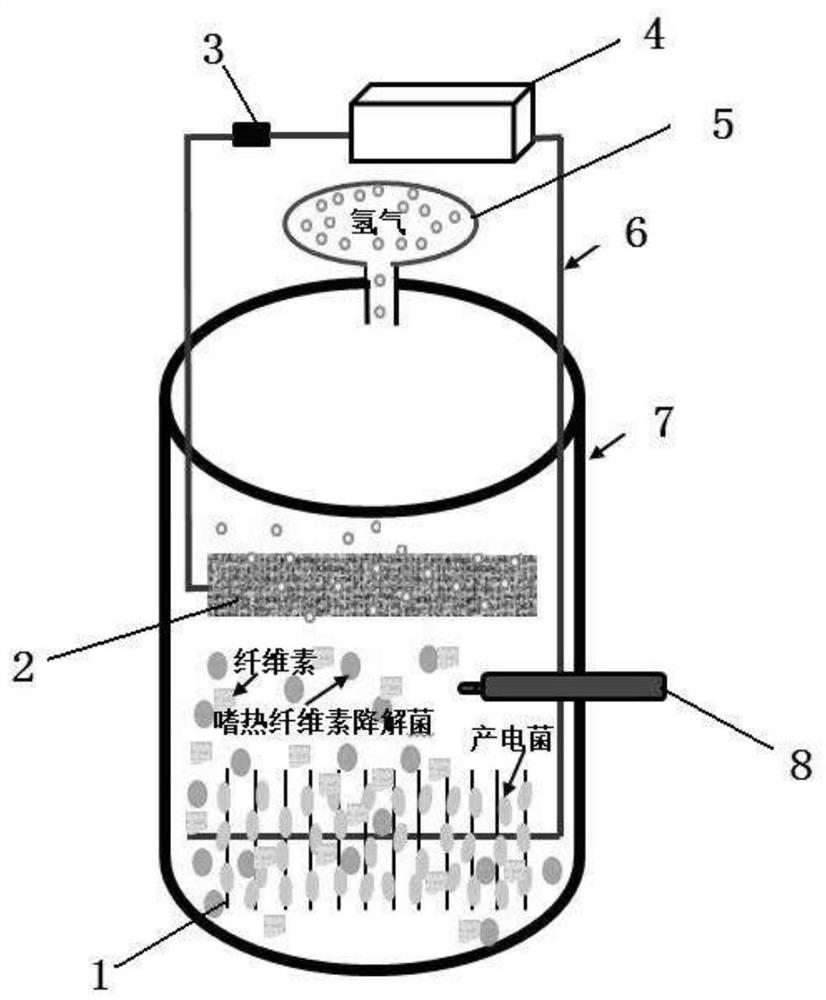

A method for efficient hydrogen recovery from cellulose by synergistic utilization of thermophilic flora based on microbial electrolysis cells

A microbial electrolytic cell and cellulose technology, applied in the field of microbial electrolytic cell hydrogen production, can solve the problems of low rate and efficiency, increased complexity and cost, and achieve the effects of shortening the cycle, promoting rapid hydrolysis and fermentation, and high metabolic activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

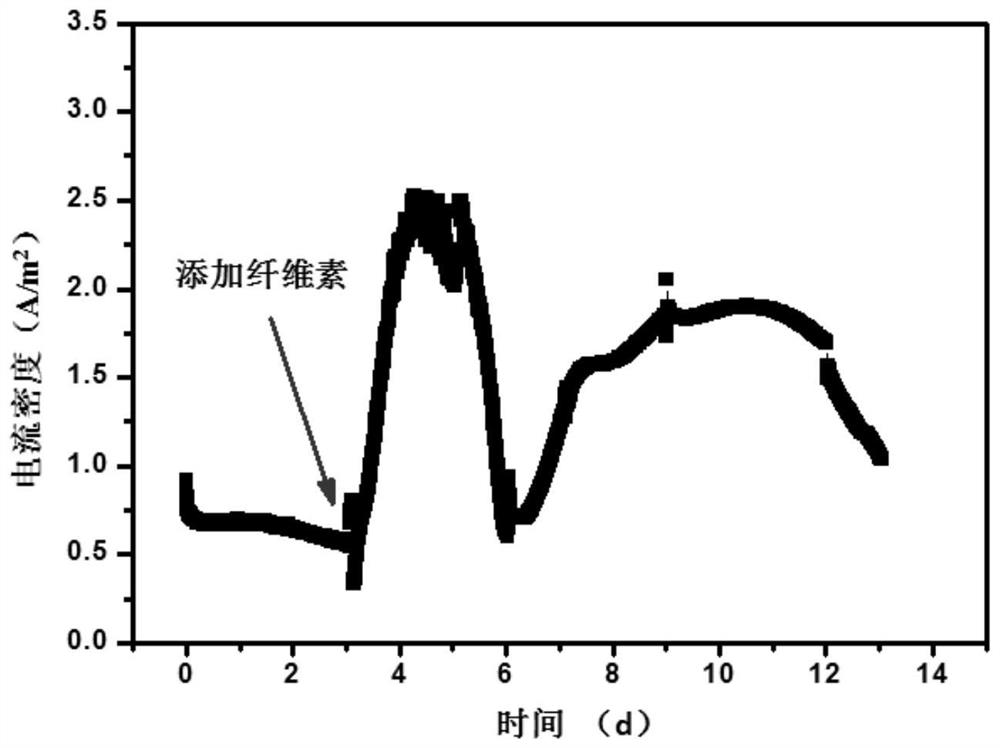

Embodiment 1

[0030] 1) Weigh 10.0g of compost and place it in a 120mL serum bottle, weigh 0.25g of cellulose filter paper (cut the filter paper into 1cm*1cm pieces), then add 100mL of matrix culture solution into the serum bottle, and reserve 20mL of top Empty locations to collect gas. The matrix culture solution is prepared by mixing basic matrix, trace elements, vitamin elements, selenate and cysteine hydrochloride solution, and each 1L of matrix culture solution contains 996mL of basic matrix, 1mL of trace element solution, vitamin solution (ATCC Vitamin) 1mL, selenate solution 1mL, cysteine hydrochloride 1mL, wherein each 1L basic matrix contains the following ingredients: NaCl 1.0g, NH 4 Cl 10.0g, MgCl 2 ·6H 2 O 1.0g, CaCl 2H 2 O 5.0g; every 1L trace element solution contains the following ingredients: FeCl 2 4H 2 O 2.0g, H 3 BO 3 0.05g, ZnCl 2 0.05g, CuCl 2 2H 2 O 0.038g, MnCl 2 4H 2 O 0.05g, CoCl 2 ·6H 2 O 0.05g, NiCl 2H 2 O 0.092g, (NH 4 ) 2 Mo 7 o 24 4H 2...

Embodiment 2

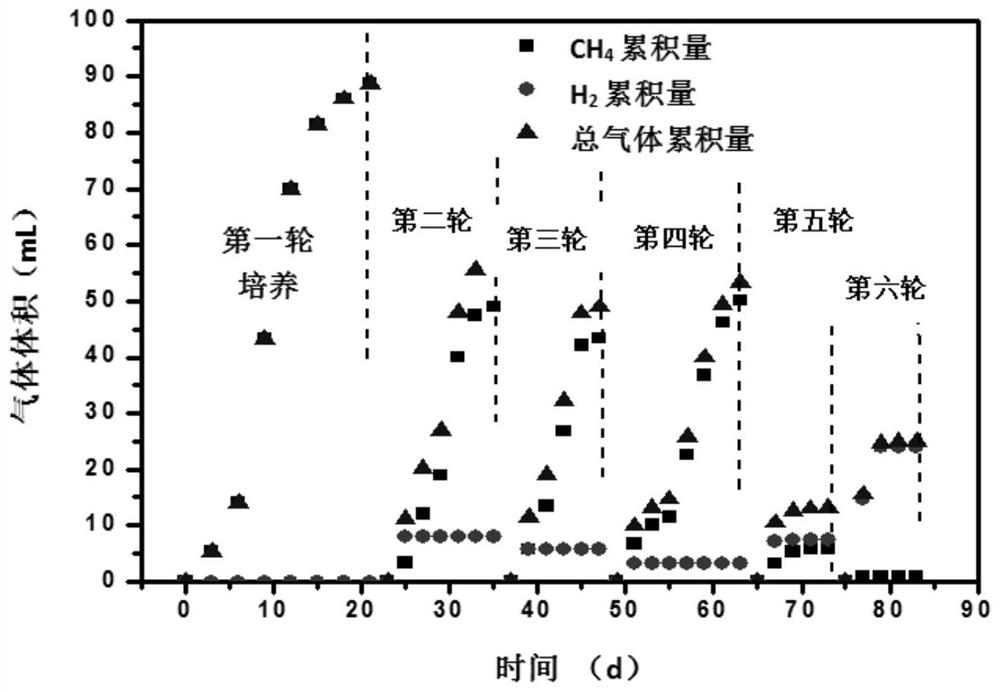

[0039] 1) Weigh 10.0g of compost and place it in a 120mL serum bottle, weigh 0.25g of cellulose filter paper (cut the filter paper into 1cm*1cm pieces), then add 100mL of matrix culture solution into the serum bottle, and reserve 20mL of top Empty locations to collect gas. The preparation of the matrix culture solution is the same as the matrix culture solution in Step 1 in Example 1. After the matrix culture solution was prepared, use N 2 / CO 2 =80 / 20 mixed gas The serum bottle added with compost, filter paper and matrix was aerated for 30 minutes to remove dissolved oxygen in the solution while maintaining the initial pH of the matrix at 7. After the aeration, the serum bottle was sealed and placed in a shaker at 55°C for cultivation. During the cultivation, the gas volume was measured every 2 days with a glass syringe, and the gas composition was measured with a gas chromatograph. A round of culture ends when the cellulose is completely dissolved and no gas is produced ...

Embodiment 3

[0045] 1) Weigh 10.0g of compost and place it in a 120mL serum bottle, weigh 0.25g of cellulose filter paper (cut the filter paper into 1cm*1cm pieces), then add 100mL of matrix culture solution into the serum bottle, and reserve 20mL of top Empty locations to collect gas. The culture solution includes a basic matrix, trace elements, vitamin elements, selenate and cysteine hydrochloride solution, and the preparation of the matrix culture solution is the same as the matrix culture solution in Step 1 in Example 1. After the matrix culture solution was prepared, use N 2 / CO 2 =80 / 20 mixed gas The serum bottle added with compost, filter paper and matrix was aerated for 30 minutes to remove dissolved oxygen in the solution while maintaining the initial pH of the matrix at 7. After the aeration, the serum bottle was sealed and placed in a shaker at 55°C for cultivation. During the cultivation, the gas volume was measured every 2 days with a glass syringe, and the gas compositio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com