Experimental method for fracturing gas-containing coal body through multi-field coupling controllable shock waves

An experimental method, shock wave technology, applied to the analysis of solids, suspensions, and porous materials using sound waves/ultrasonic waves/infrasonic waves, and material analysis using sound wave emission technology, which can solve problems such as large construction volume, complicated process, and high cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

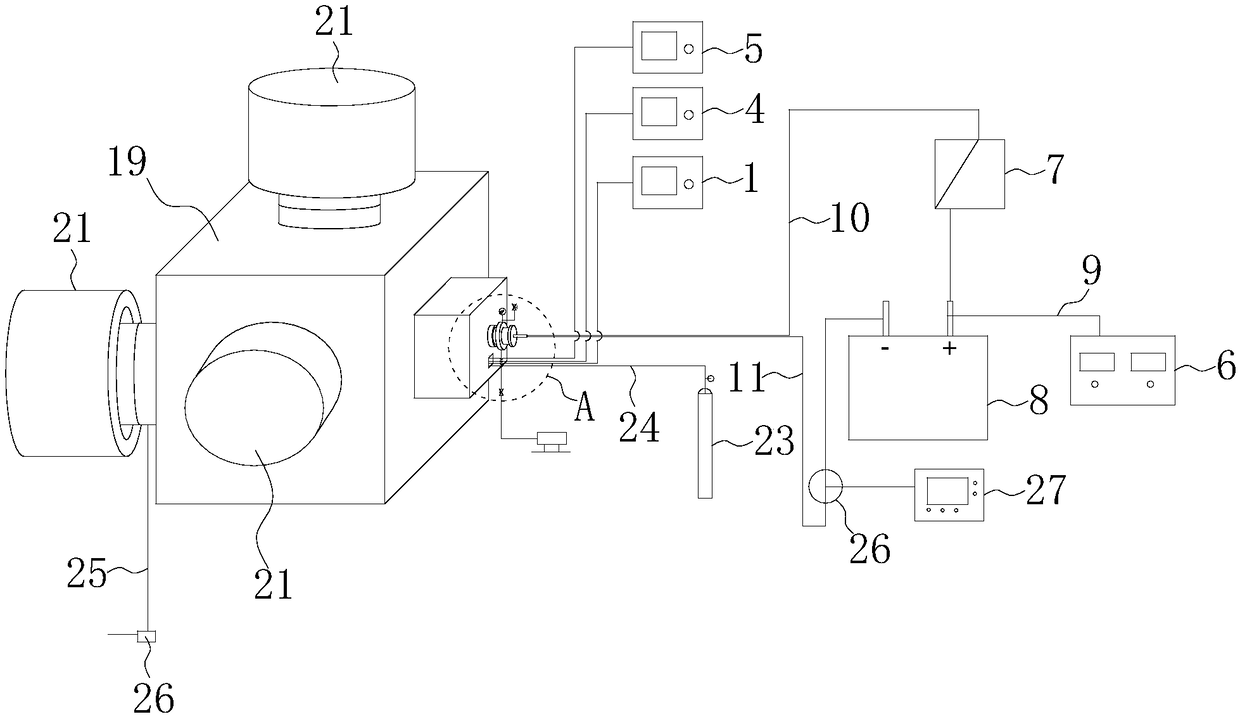

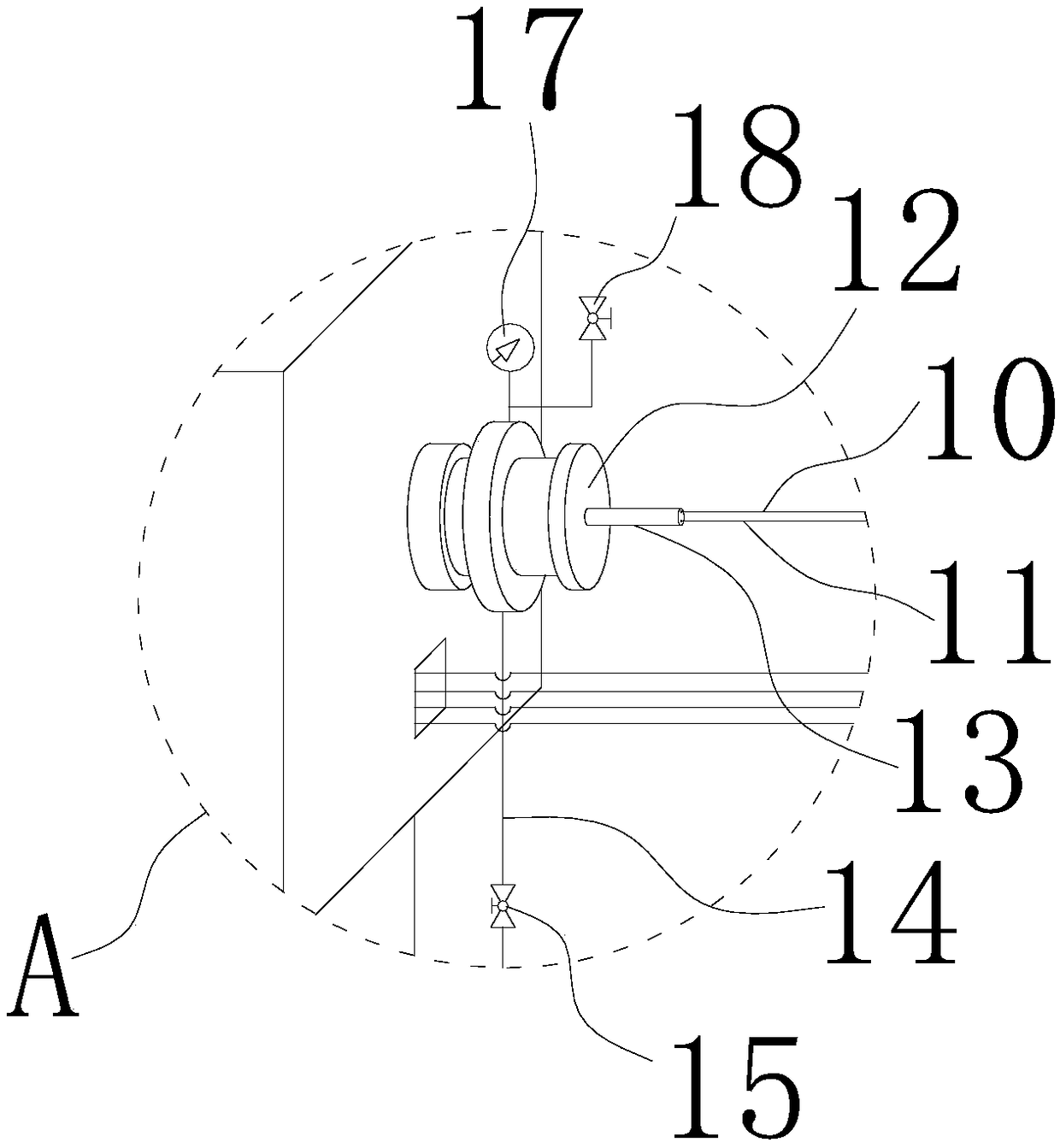

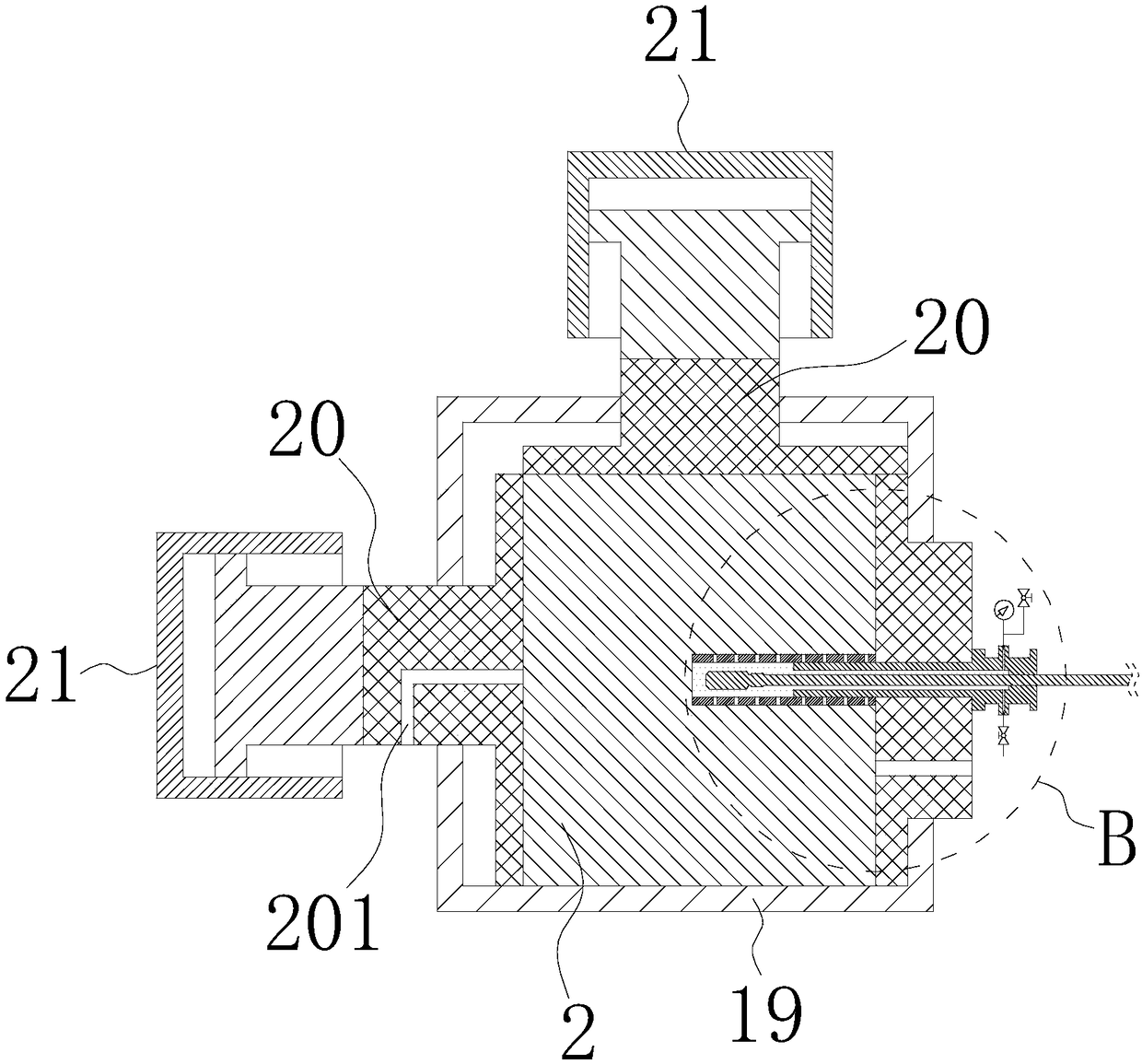

[0094] An experimental method for cracking gas-containing coal bodies by multi-field coupled controllable shock waves, including

[0095] Step a: making a coal sample 2, presetting a borehole 3 on the coal sample 2, and injecting a certain pressure liquid into the borehole 3;

[0096] Step b: installing a high-power pulse generating mechanism, and connecting the high-power pulse generating mechanism to the borehole 3 with wires;

[0097] Step c: install the shock wave detection mechanism 1;

[0098] Step d: Make the high-power pulse generating mechanism emit a high-power pulse to the liquid in the borehole 3, forming a shock wave in the liquid to crack the coal sample 2;

[0099] Step e: Using the shock wave detection mechanism 1 to detect and analyze the shock wave characteristics in the coal sample 2 .

[0100] The high-power pulse in this application refers to a pulse with a pulse power above 10KW. The shock wave detection mechanism 1 in the above scheme can be a common ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com