Welding-free strip light port power supply connector and welding-free strip light power supply connection method

A technology of power connectors and light strips, which is applied in the direction of connection and connection of parts and circuits of devices, can solve problems such as safety risks, line failures, poor construction quality, etc., and achieve the effect of simplifying operating procedures and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

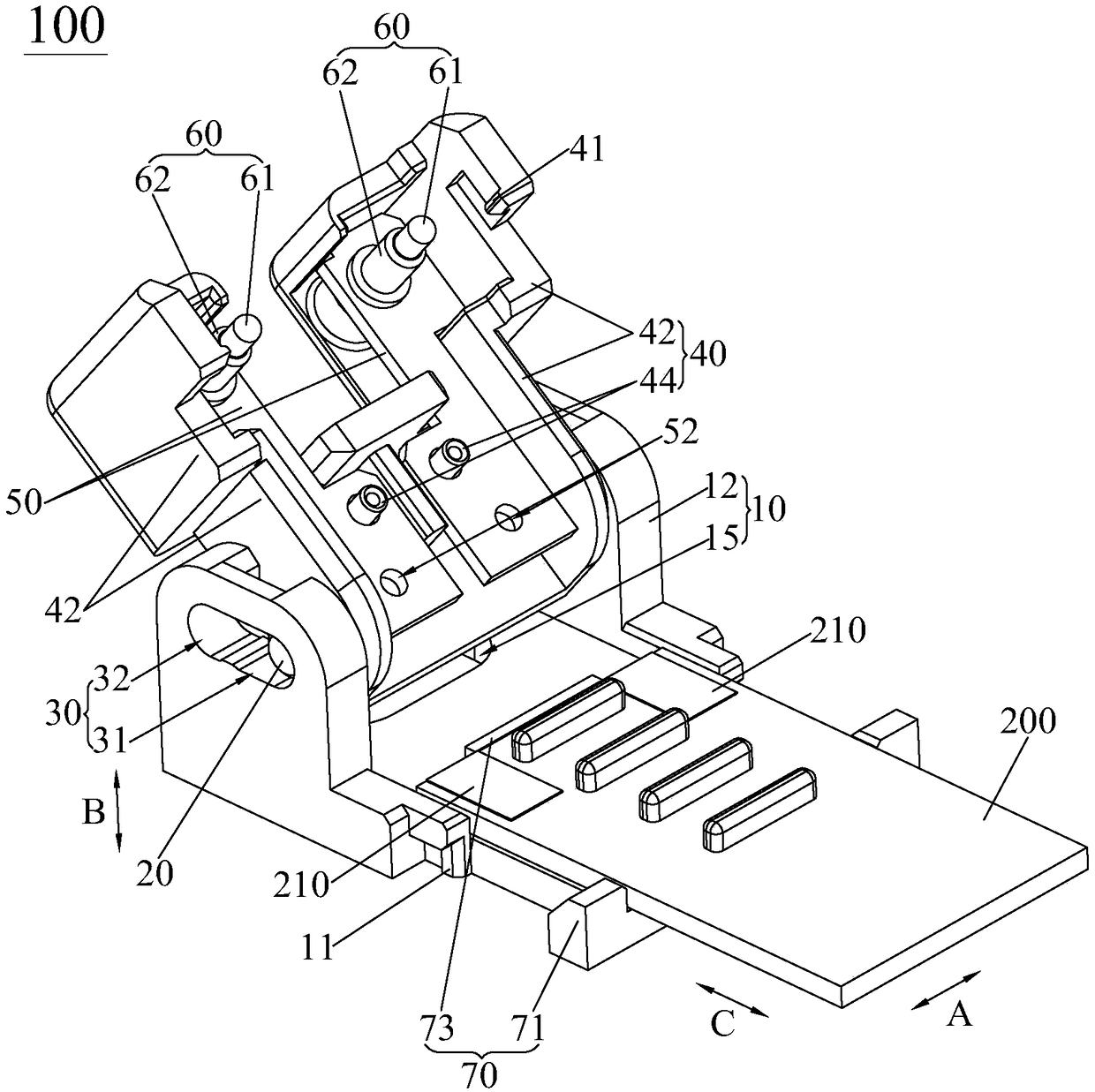

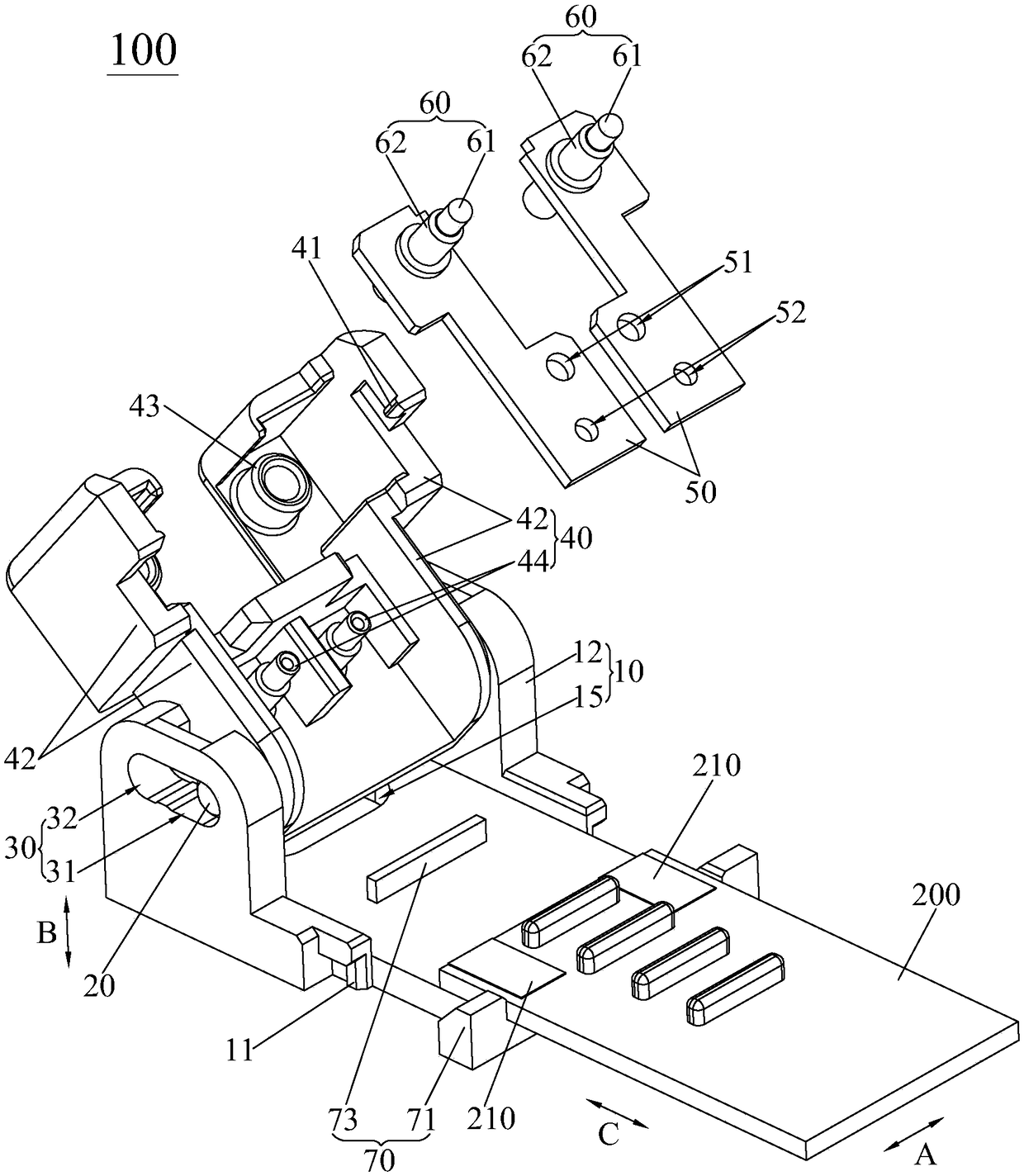

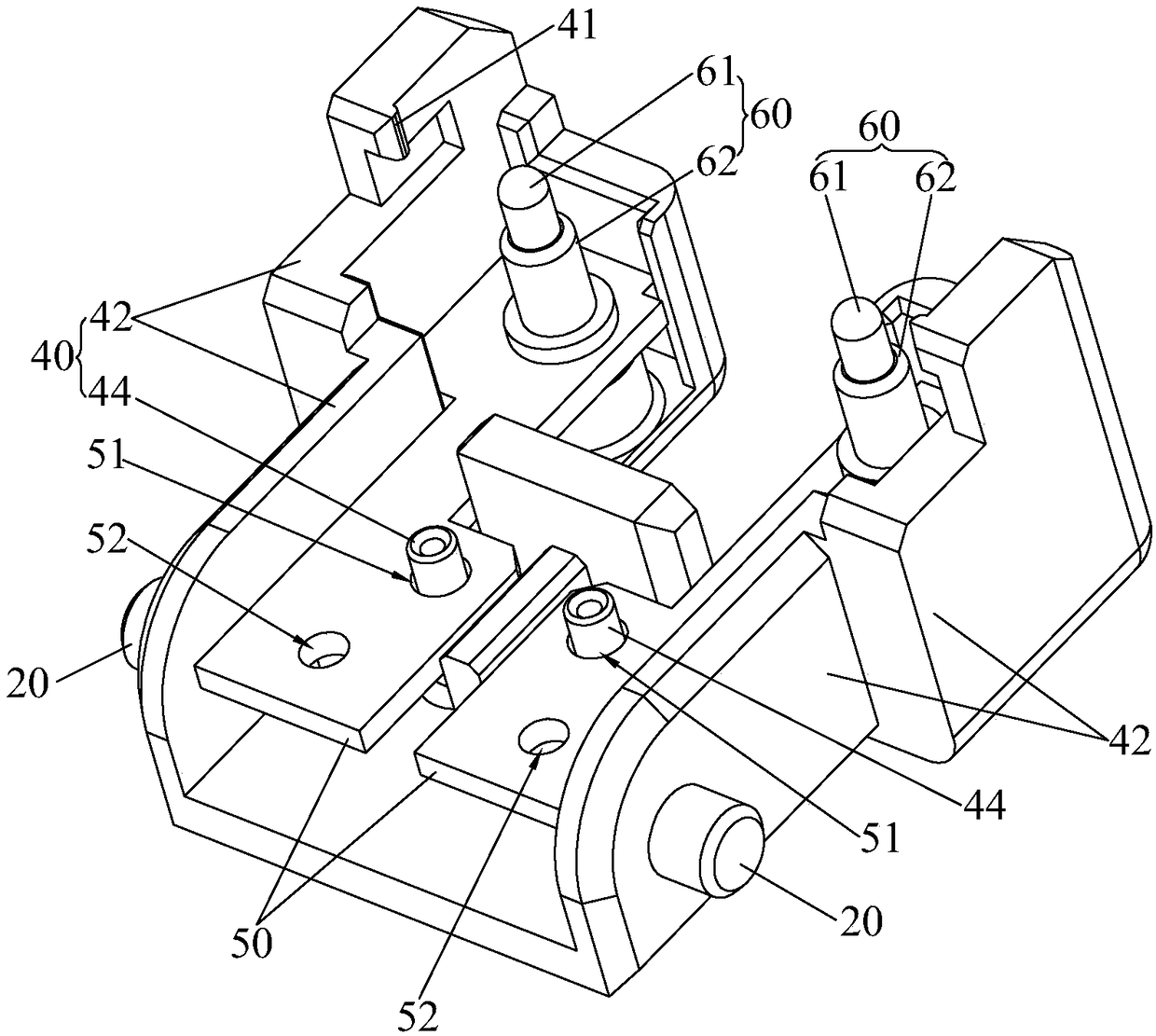

[0031] In order to describe the technical content and structural features of the present invention in detail, further description will be given below in conjunction with the implementation and accompanying drawings.

[0032] see figure 1 , Figure 6 and Figure 7 , the solderless light strip port power connector 100 of the present invention includes a base 10 for carrying the light strip 200 , a cover that turns over a mounting axis 20 relative to the base 10 and slides relative to the base 10 along a guide rail 30 40. The PCB board 50 installed on the cover 40 and the probe 50 pierced on the PCB 40. Preferably, the probe 40 is along the upper and lower sides of the seat 10 when the cover 40 is in the cover position described below. The direction is set at the PCB board 40, but not limited thereto. The installation shaft 20 is arranged along the left-right direction of the seat body 10 (i.e. the direction indicated by the double arrow A), so that the cover body 40 moves up ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com