Novel kerosene processing treatment device for aerospace

A technology for aerospace and processing equipment, applied in the aerospace field, can solve the problems of unsatisfactory filtration effect, low filtration efficiency, complicated operation, etc., and achieve significant effect of filtration and filter pressure, saving time. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

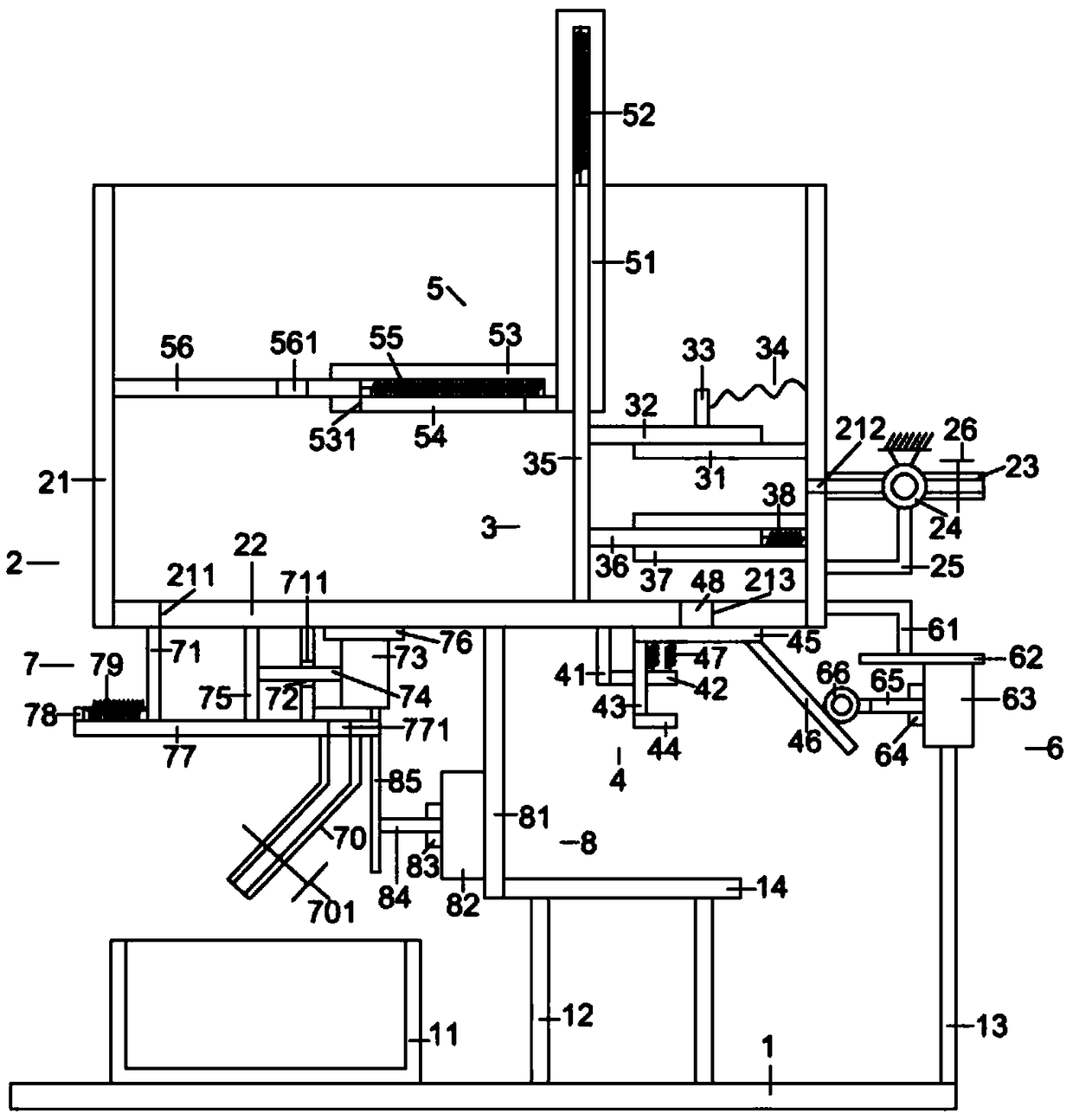

[0009] The novel kerosene processing equipment for aerospace use of the present invention will be clearly and completely described below in conjunction with the accompanying drawings.

[0010] like figure 1 As shown, the novel kerosene processing equipment for aerospace of the present invention includes a base plate 1, a frame device 2 positioned above the base plate 1, a pushing device 3 accommodated in the frame device 2, and a The blocking device 4 on the body device 2, the filter press device 5 arranged on the pushing device 3, the electric cylinder device 6 located above the bottom plate 1, the stirring device 7 arranged below the frame device 2, the setting The driving device 8 on the stirring device 7.

[0011] like figure 1 As shown, the base plate 1 is a cuboid, and the base plate 1 is provided with a recovery box 11 above it, a first support bar 12, a second support bar 13, and a first support bar 12 above the first support bar. Fixed rod 14. The recovery box 11 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com