A waterproof cover and a waterproof assembly for a JP cabinet

A waterproof cover and component technology, applied in the field of transformers, can solve the problems of limited ventilation, water leakage, affecting the temperature rise of JP cabinets, etc., and achieve the effect of facilitating later maintenance and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

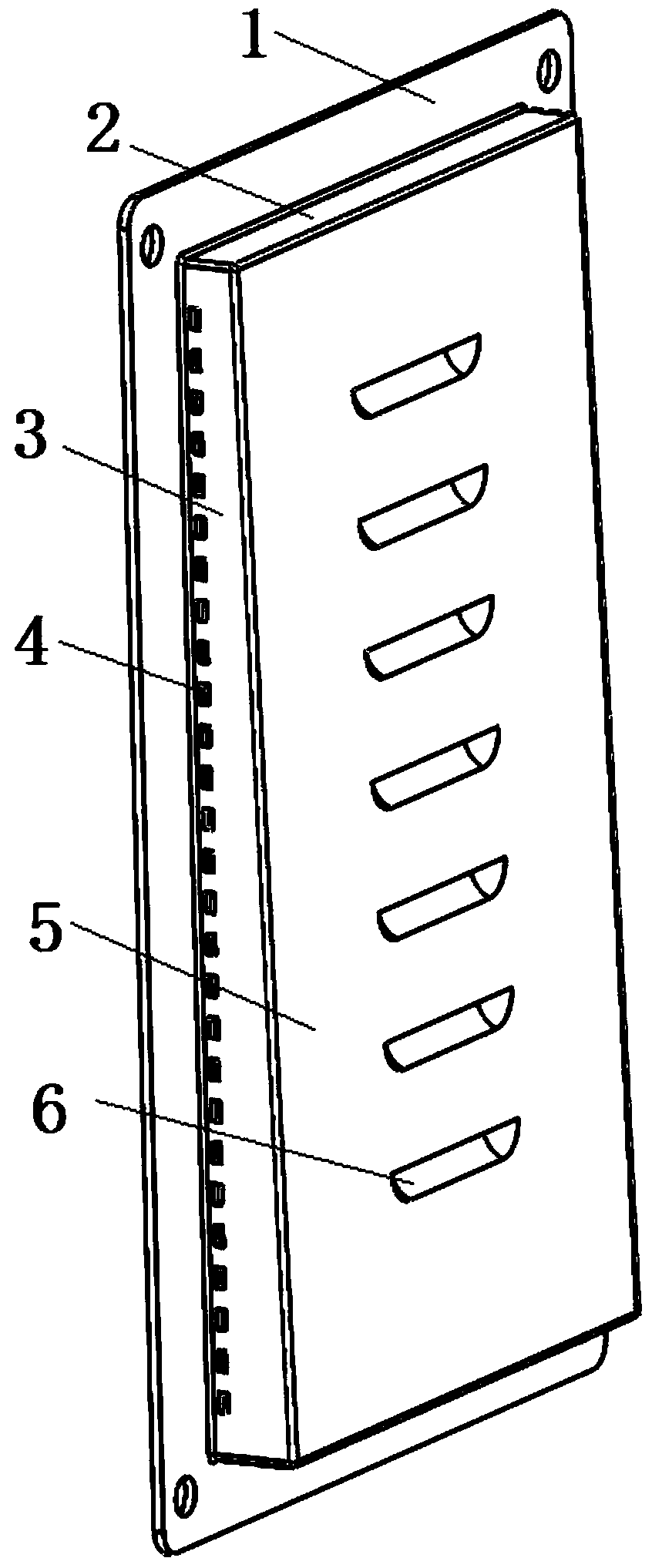

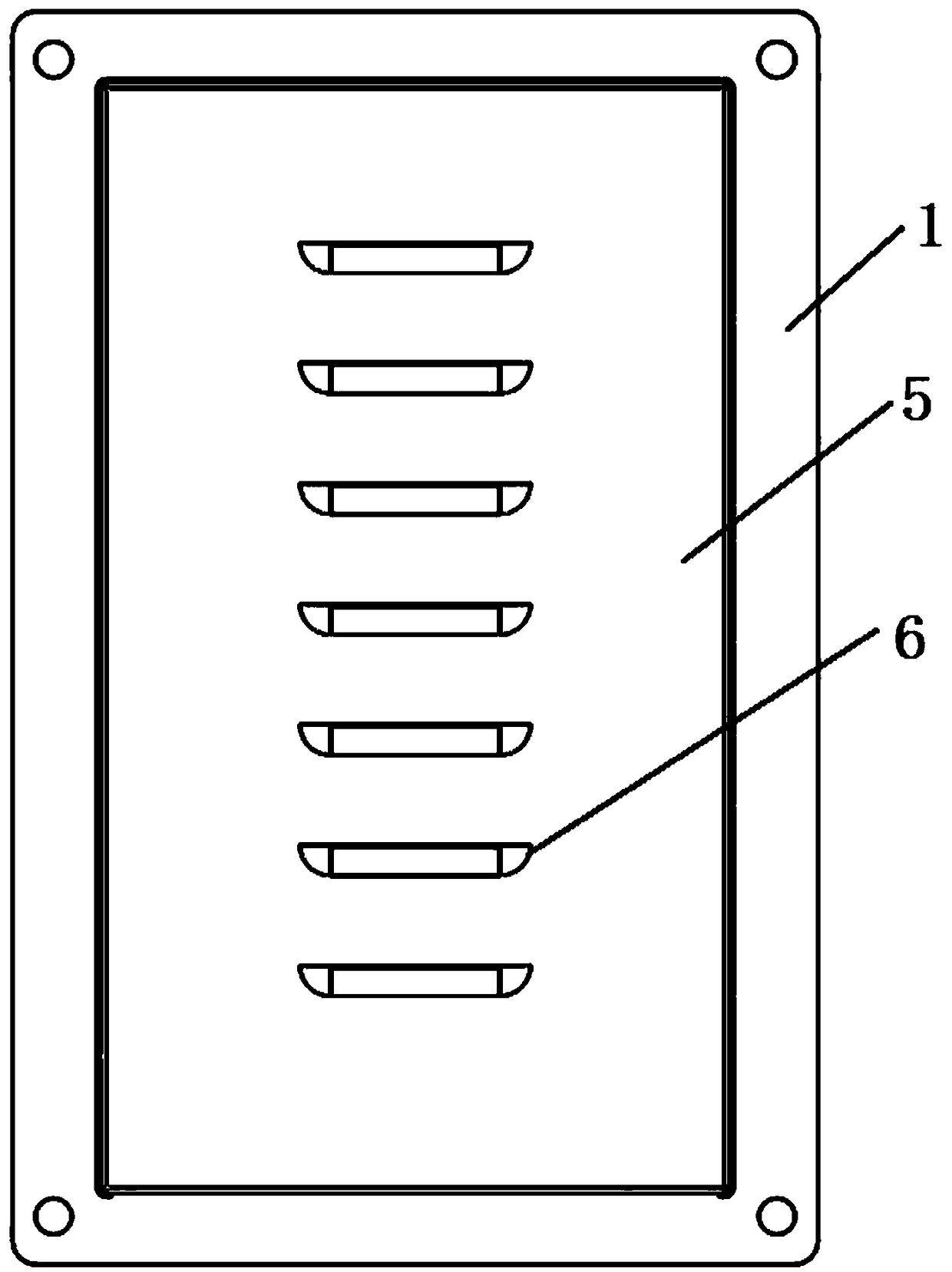

[0025] This embodiment provides a waterproof cover for a JP cabinet. The waterproof cover is made of ABS flame-retardant material with a grade of V-0. The basic design idea is that the front of the waterproof cover is flat and raised, and the side is a wedge-shaped structure with a narrow top and a wide bottom; ventilation louvers are designed on the front of the waterproof cover to increase ventilation and prevent splashing water.

[0026] Specific structural design such as Figure 1-4 As shown, the waterproof cover includes a mounting plate 1, left and right side plates 3, an upper top plate 2, a lower bottom plate 7, and a cover plate 5. The left and right side plates 3 are wedge-shaped structures with a narrow top and a wide bottom, and the cover plate 5 is a flat plate. The first ventilation louvers 6 are arranged on the plate 5, and the first ventilation louvers 6 extend into the inner side of the cover plate 5 and are inclined upward.

[0027] The left and right side p...

Embodiment 2

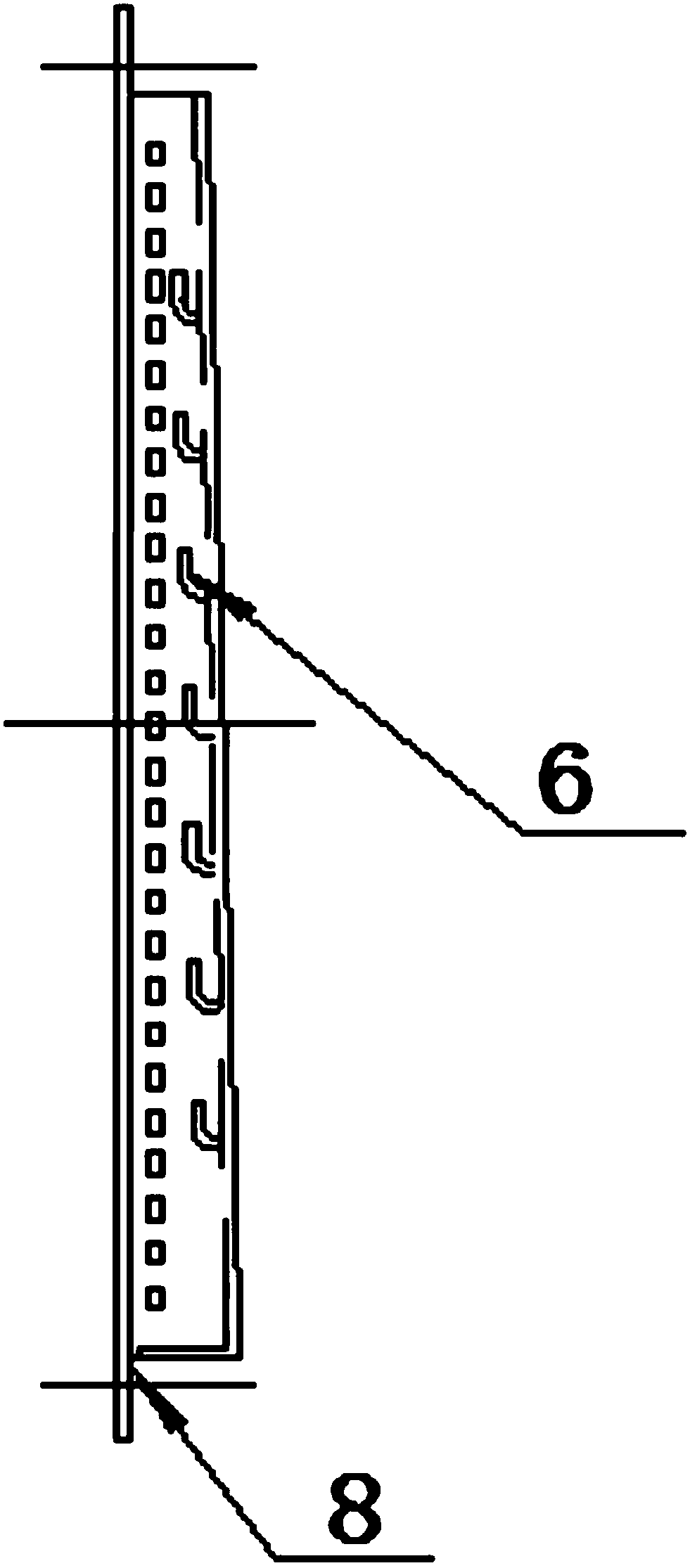

[0030] like Figure 5-6 As shown, this embodiment provides a waterproof assembly for a JP cabinet, which includes a stainless steel mesh plate 9 and a side wall 10 of the JP cabinet in addition to the waterproof cover described in Embodiment 1. The waterproof cover is fixed on the inside of the side wall 10 of the JP cabinet through bolt fasteners (fastening bolts 12 and nuts 13), and the stainless steel mesh plate 9 is located between the waterproof cover and the side wall 10 of the JP cabinet, and is fixed to the JP cabinet by the flange of the waterproof cover. Cabinet side wall 10 inside. The stainless steel screen 9 adopts 304 stainless steel screen, the grid gap is less than or equal to 0.6mm, the stainless steel screen and the waterproof cover work together, and the protection level of the cabinet reaches IP44.

[0031] The second ventilation louver 11 is provided on the side wall 10 of the JP cabinet, and the second ventilation louver 11 stretches out from the outside...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com