A bridge support and its installation method

A bridge bearing and bearing plate technology, applied in bridges, bridge construction, bridge parts, etc., can solve the problems of complex use of bridges and indeterminate horizontal displacement directions, so as to improve the service life, weaken the force, and increase the adaptability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

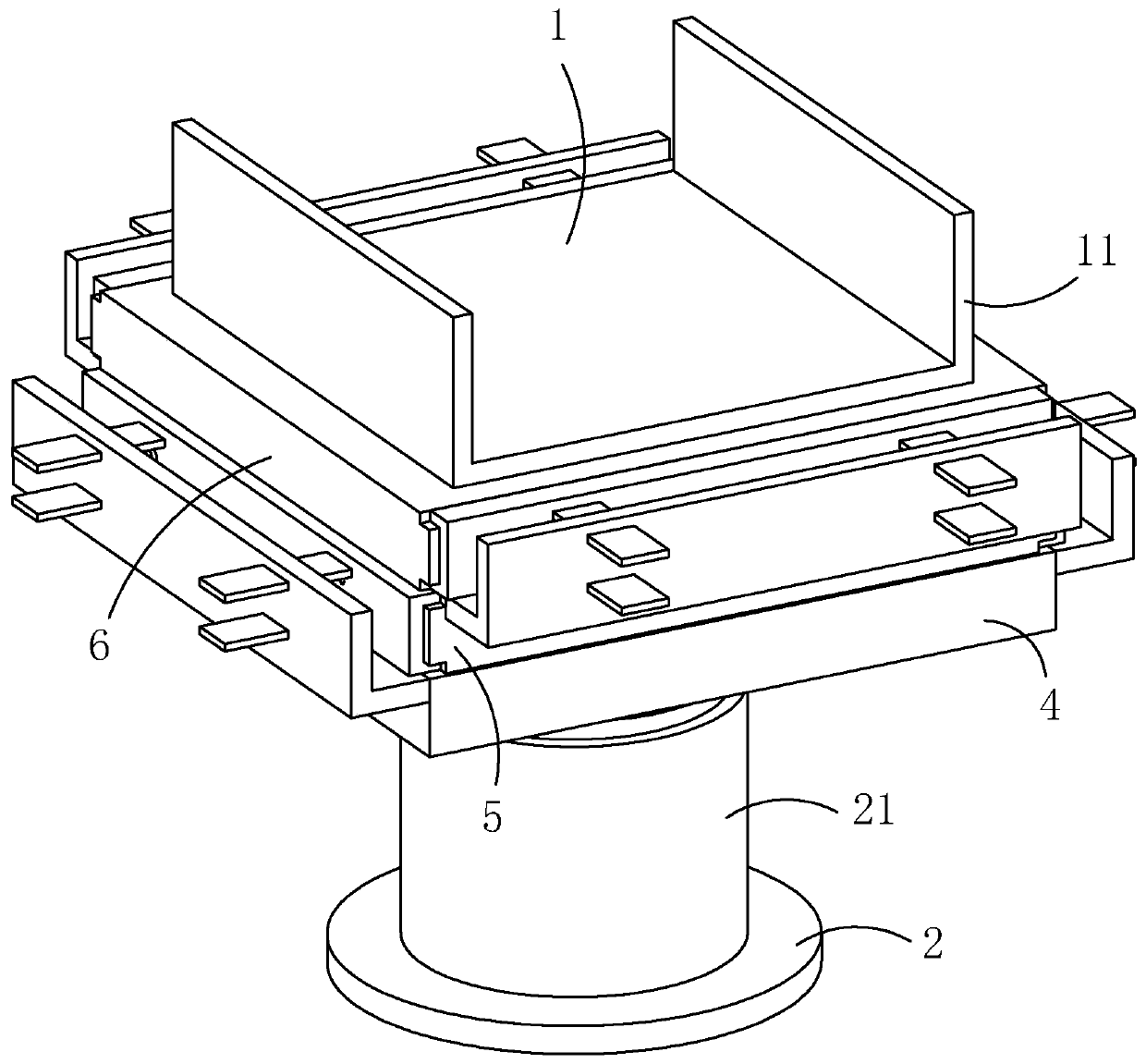

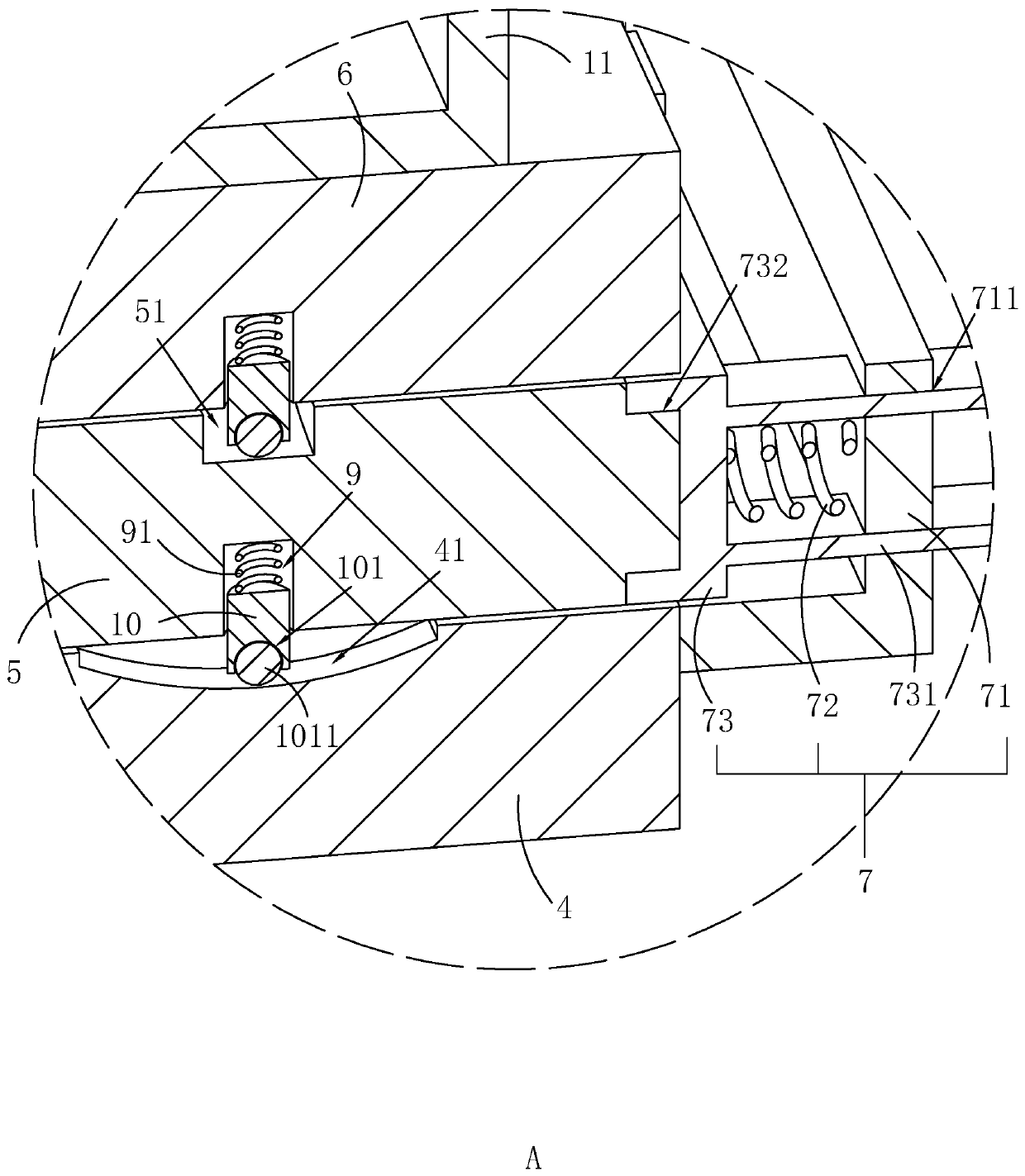

[0046] Such as figure 1 , 2 As shown, a bridge bearing includes an upper bearing plate 1 connected to the bridge girder body, on which the upper bearing plate 1 is fixedly connected with a pre-embedded steel plate 11, two pre-embedded steel plates 11 are arranged, and are connected to the lower support of the bridge pier The seat plate 2 and the rubber bearing 3 arranged between the upper support plate 1 and the lower support plate 2 (see Figure 4 ), also includes a support plate 4 , a first slide plate 5 and a second slide plate 6 , and the support plate 4 is arranged on the rubber support 3 .

[0047] Such as figure 2 , 3 As shown, the upper surface of the support plate 4 is provided with a first guide groove 41, the first slide plate 5 is slidably arranged on the support plate 4, and the first slide plate 5 is provided with a first sliding connection with the first guide groove 41. Sliding part; the second sliding plate 6 is slidably arranged on the first sliding plat...

Embodiment 2

[0059] A method for installing a bridge support, comprising the following steps:

[0060] Step 1. The pre-embedded steel plate 11 of the bridge girder body is installed. First, according to the number and layout position of the rubber bearings 3 set on the bridge pier, during the prefabrication process of the bridge girder body, each rubber bearing 3 is pre-embedded at the bottom of the bridge girder body. The pre-embedded steel plate 11 at the bottom of the beam;

[0061] Step 2. Install the rubber support 3, install the lower support plate 2 on the pier, then install the rubber support 3 on the lower support plate 2, and then install the support plate 4, the first movable plate and the second movable plate in sequence , through the laser locator for installation and positioning to ensure the accuracy of the installation;

[0062] Step 3, drop the beam, hoist the bridge beam body with the pre-embedded steel plate 11 embedded at the bottom, and drop the bridge beam body until...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com