Water treatment system for marine low speed diesel engine egr

A water treatment system, diesel engine technology, applied in the direction of charging system, mechanical equipment, engine components, etc., to achieve the effect of reducing human intervention, reducing workload, and small size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050] The water treatment system for marine low-speed diesel engine EGR of the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments, but the protection scope of the present invention should not be limited thereby.

[0051] The present invention consists of three parts: a set of circulating water buffer tanks for circulating water supply, treatment and monitoring; a set of NaOH solution tanks for storing, heating and supplying NaOH solution; a set of both local control and remote control functions An integrated control system for automatically controlling the treatment, supply, discharge, heating, detection, etc. of circulating water and NaOH solution.

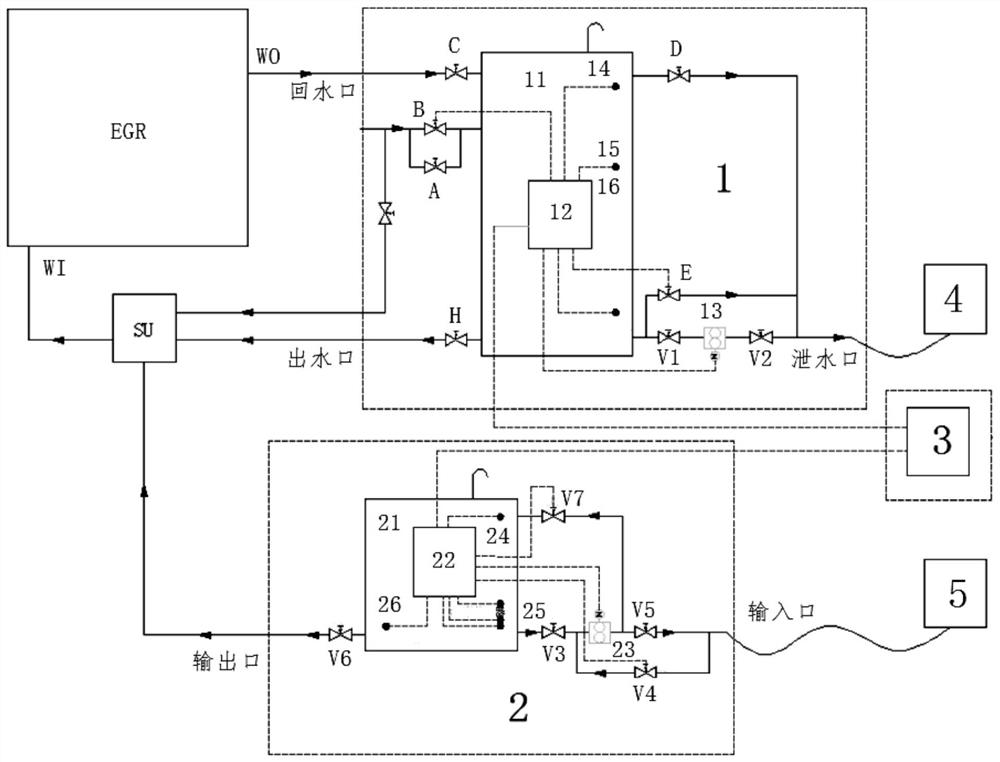

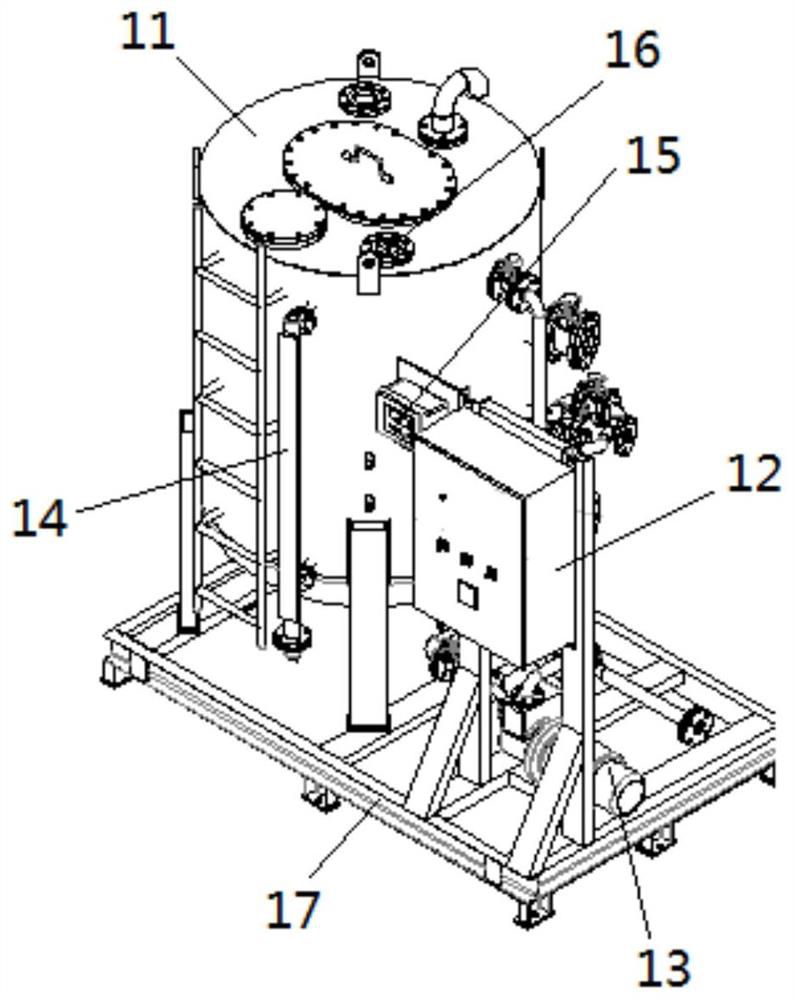

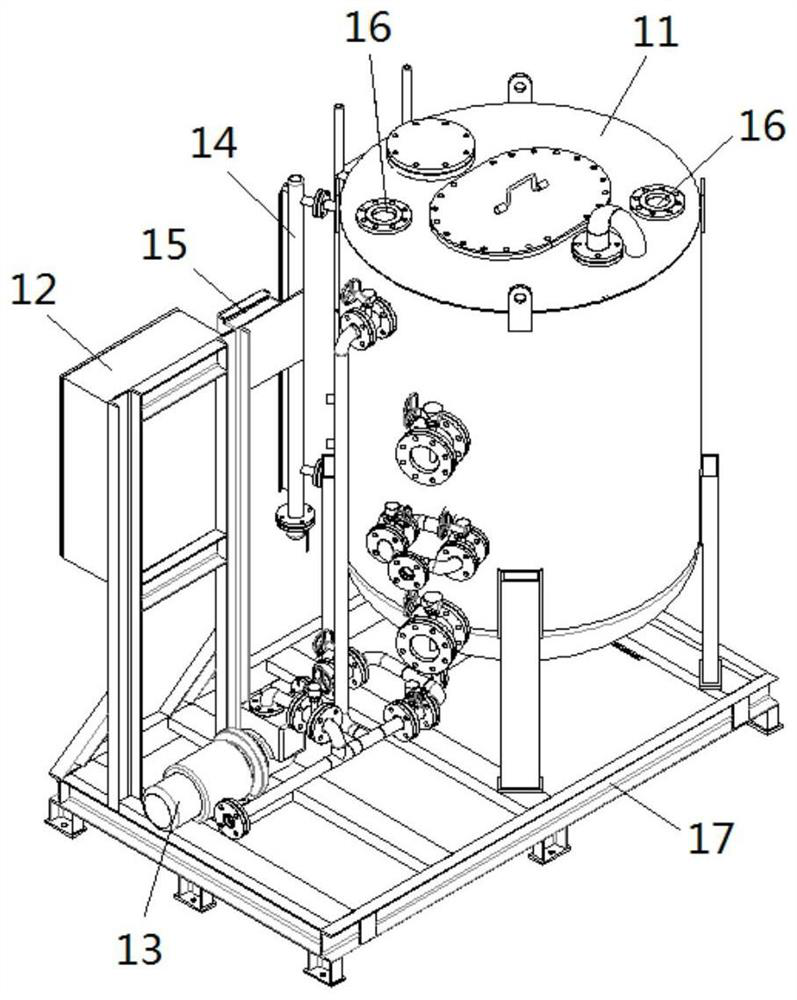

[0052] see figure 1 , the entire water treatment system for marine low-speed diesel engine EGR includes a circulating water buffer tank 1 , a NaOH solution tank 2 and a control system 3 .

[0053] The function of the circulating water buffer tank 1 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com