Rotogravure with snubber roll

A technology of gravure printing and printing mechanism, which is applied to gravure rotary printing machines, printing machines, rotary printing machines, etc. It can solve the problems of lost settings, web tension changes, etc., and achieve good registration accuracy and fast adjustment effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

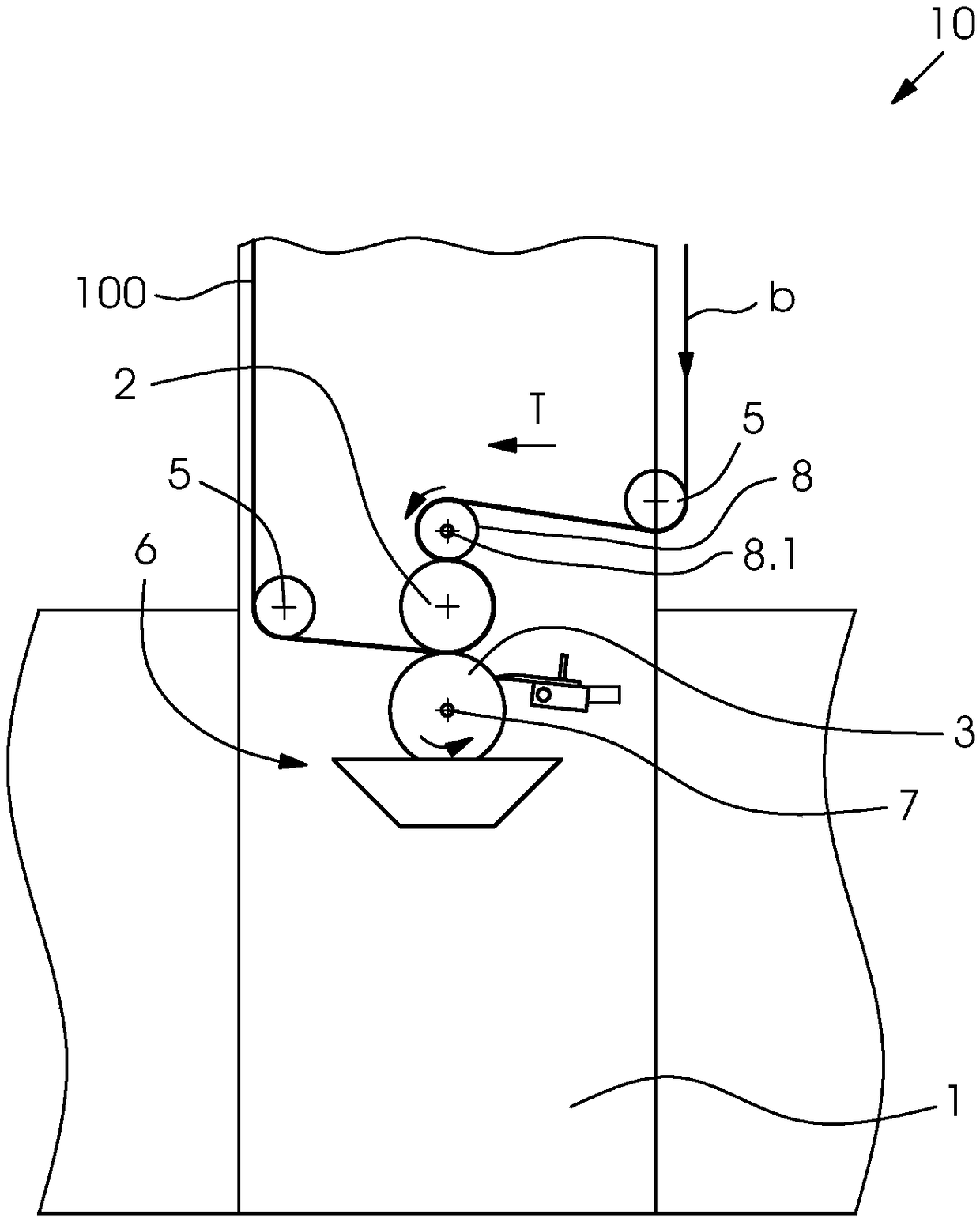

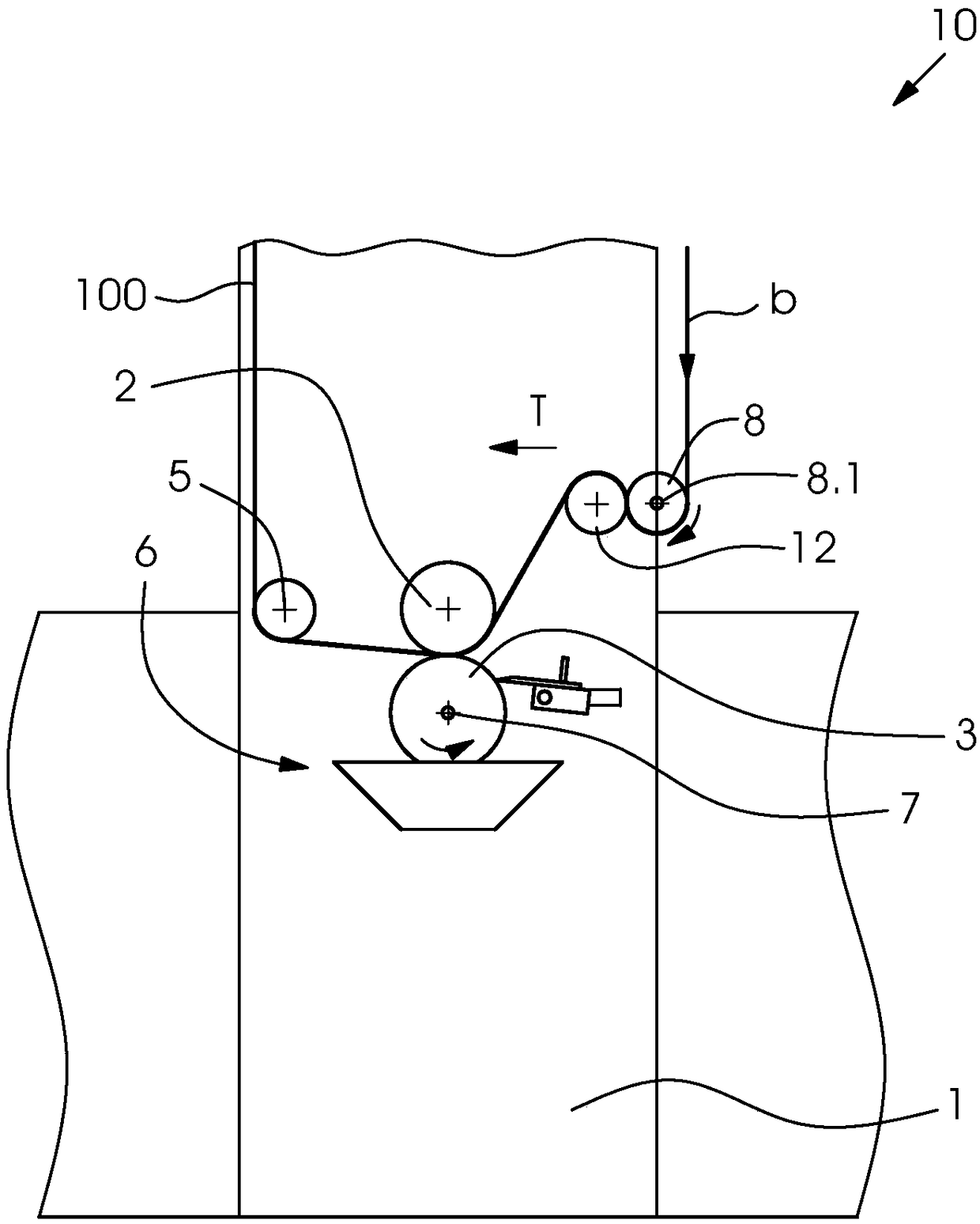

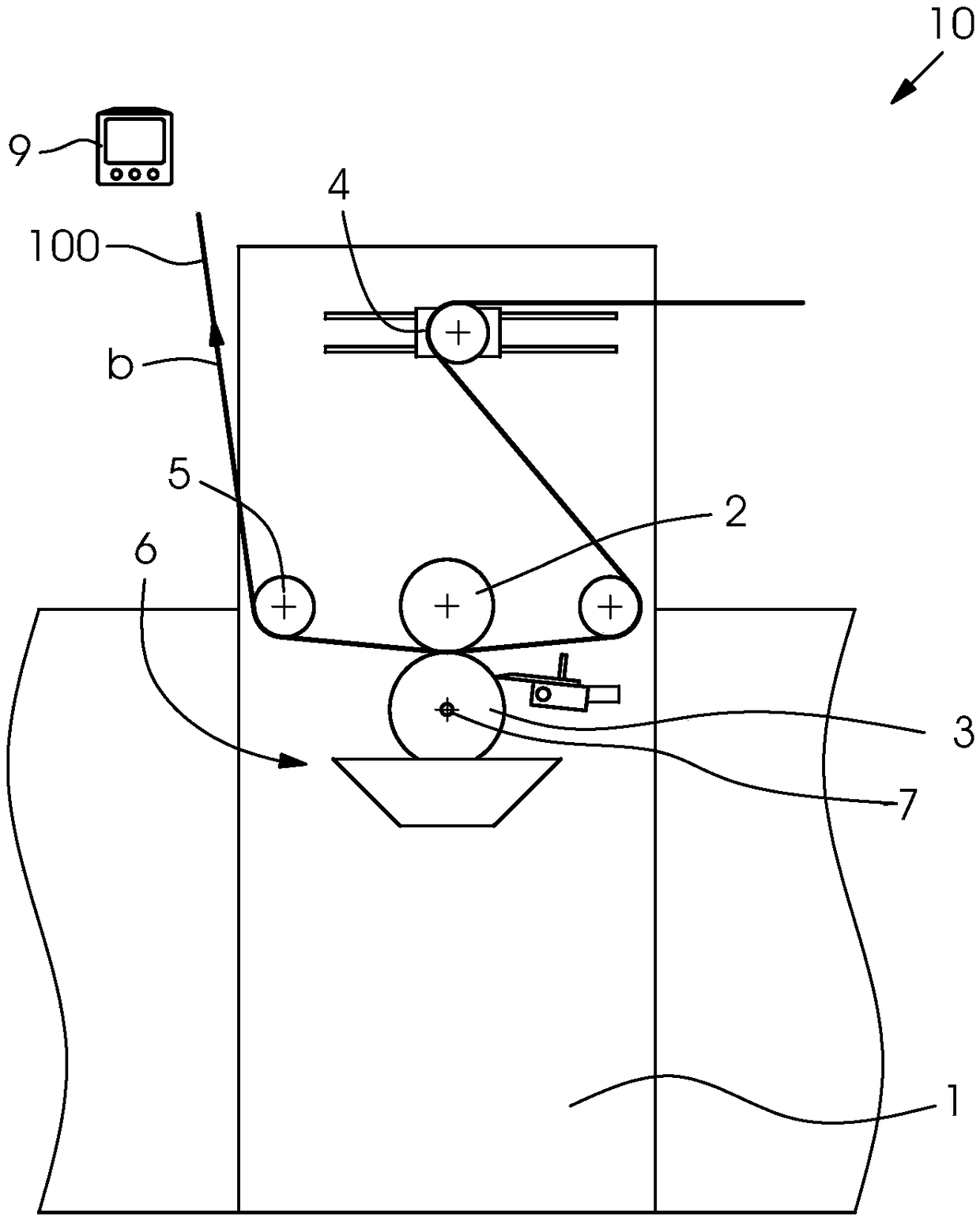

[0027] exist image 3 A rotogravure printing unit 10 according to the prior art is shown in , in which a printing material web 100 is printed. The support structure of the printing unit 10 is formed by the printing unit carrier 1 . As indicated by the arrow b, the printing material web 100 runs through the rotogravure printing unit 10 in such a way that the printing material web 100 passes through a not-shown pre-printing unit or pre-processing station via the web The belt tension compensation device 4 enters the gravure printing mechanism 10, and the printing material web 100 is guided through the gravure printing cylinder 3 and the pressure roller 2 by the first guide roller 5 (here the printing material web 100 is printing), and then, before the printing material web 100 leaves the gravure printing mechanism 10 and is further conveyed to a subsequent, not-shown further printing mechanism or a subsequent, not-shown processing station, the printed The material web 100 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com