River sewage sampler

A sampler and sewage technology, applied in sampling, sampling devices, instruments, etc., can solve the problems of single structure, high labor intensity of staff, inability to sample river water, etc., and achieve the effect of improving safety and reducing labor intensity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

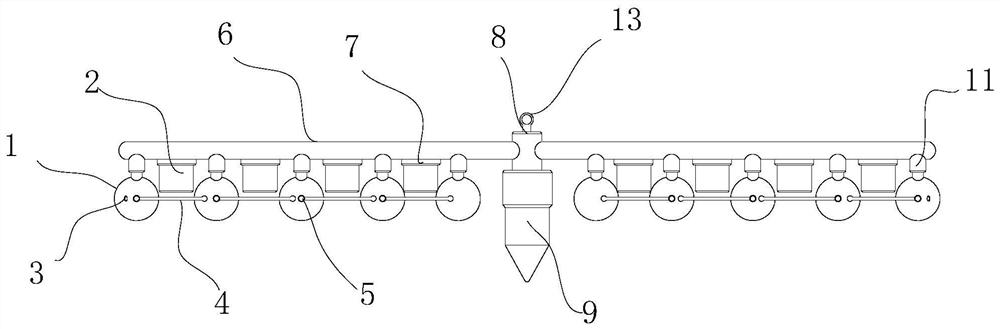

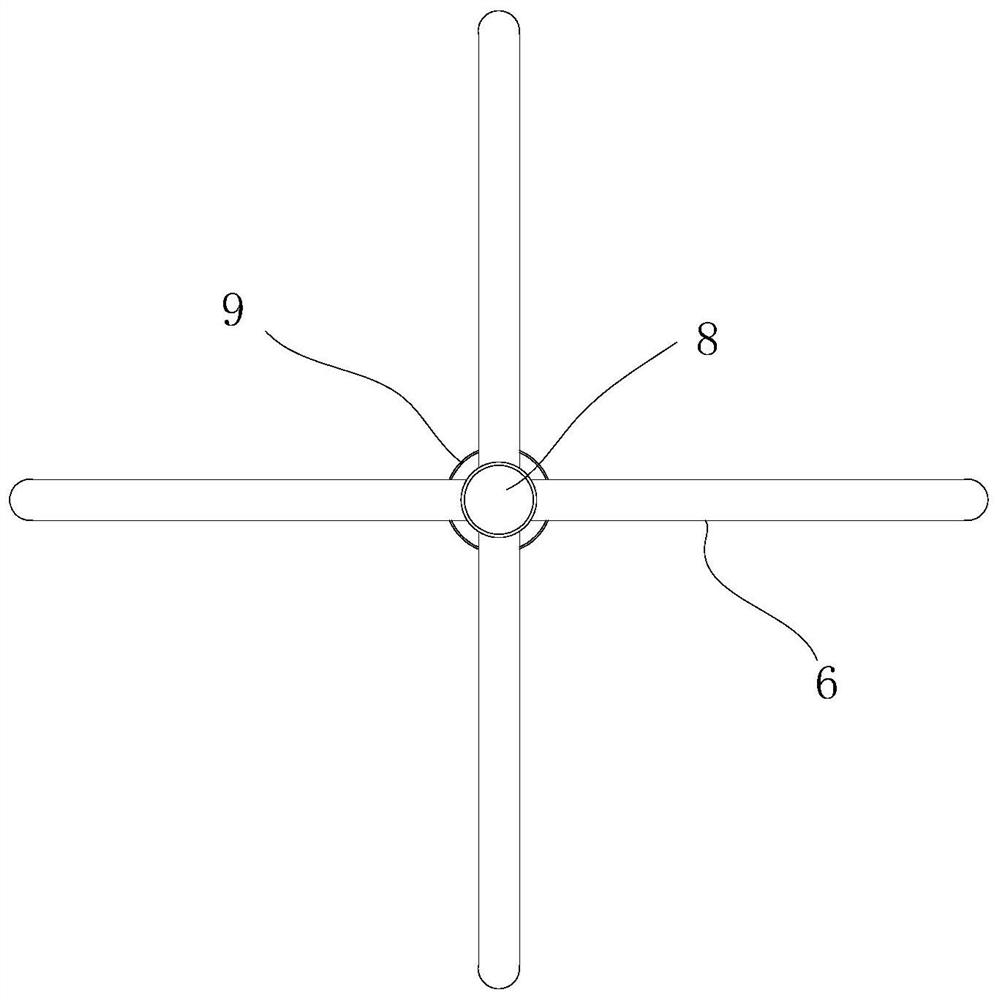

[0016] Such as figure 1 and figure 2 Shown, this river channel sewage sampler comprises a central axis 8, and the bottom of central axis 8 is welded a counterweight body 9 with an outer diameter greater than the central axis outer diameter, and four faces of central axis 8 are vertically welded a support plate 6, and the support plate The lower end surface of 6 is equidistantly welded with more than one fixed shaft sleeve 11, and the bottom of the fixed shaft sleeve 11 is all loaded with a sampling ball 1, and a convex portion is arranged on the top of the sampling ball 1, and the convex portion is loaded into the lower end surface of the fixed shaft sleeve 11 In the fixed hole opened;

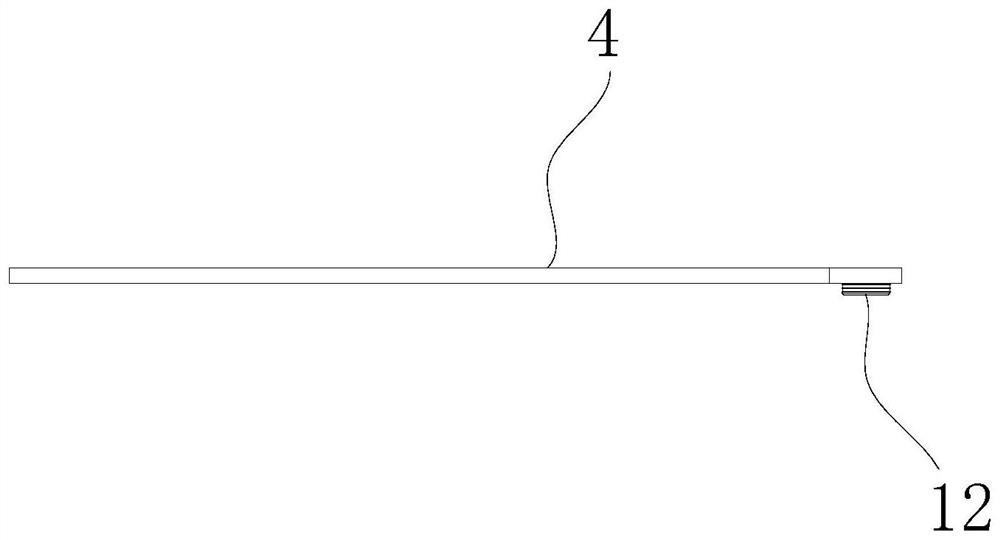

[0017] Wherein, one side of the sampling ball 1 is bonded with a fixed piece 5 by waterproof glue, the sampling ball on the opposite side of the fixed piece 5 is provided with a connecting piece 4, and the same side of the sampling ball 1 and the fixed piece 5 is provided with a water suctio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com